Loading ...

Loading ...

Loading ...

11

TABLE 1 - COOLING OIL - Dielectric

SUPPLIER GRADE

BP Enerpar SE100

Conoco Pale Paraffi n 22

Mobile D.T.E. Oil Light

G & G Oil Circulating 22

Imperial Oil Voltesso-35

Shell Canada Transformer-10

Texaco Diala-Oil-AX

Woco Premium 100

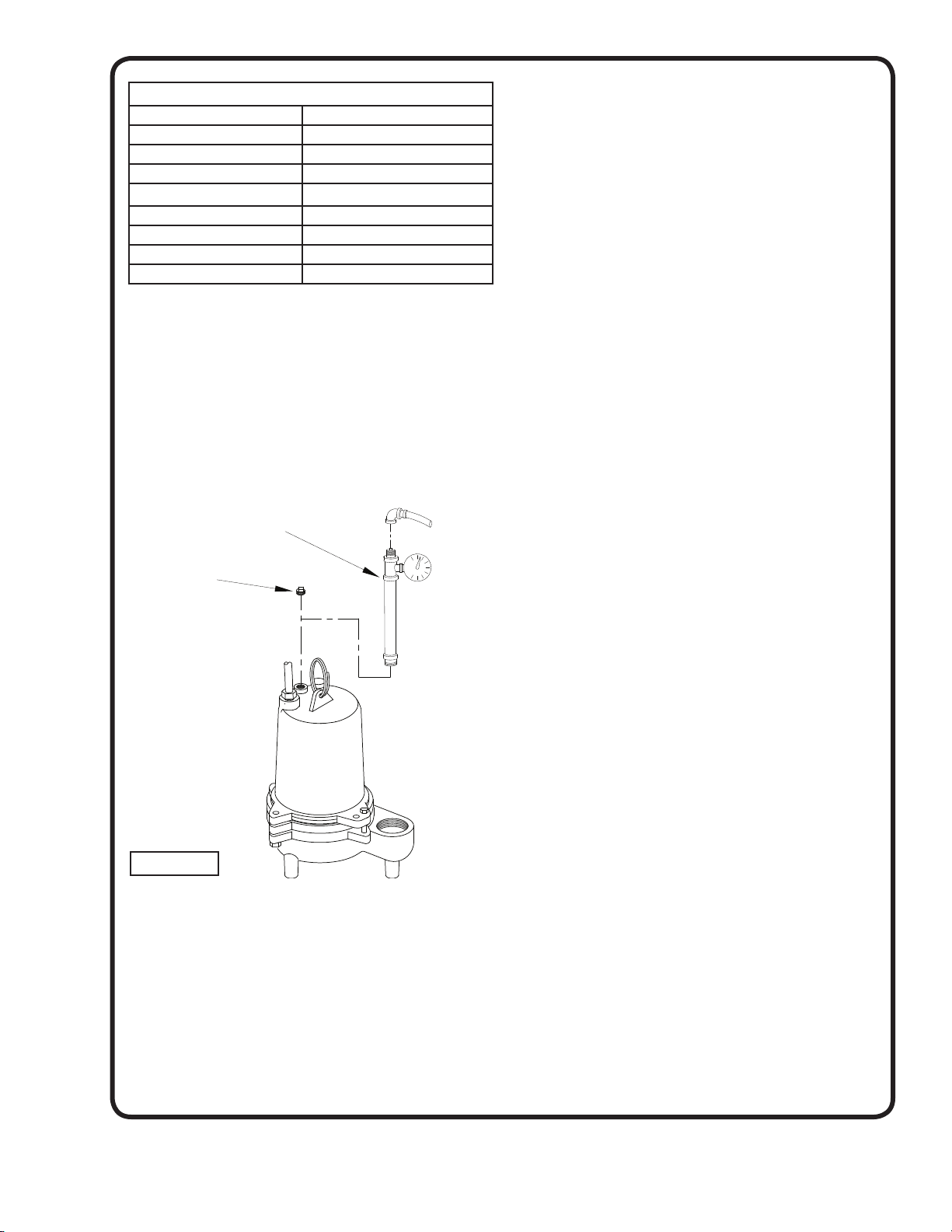

F-1.4) Pressure Test:

Before checking the pump for leaks around the shaft

seal, square ring, and cord inlet, the oil level should be

full as described in section F1.3. Apply pipe sealant to the

pressure gauge assembly and tighten into fi ll plug hole

(see fi g.4). Pressurize motor housing to 10 P.S.I. Use a

soap solution around the sealed areas and inspect joints

for “air bubbles”. If, after fi ve minutes, the pressure is still

holding constant, and no “bubbles” are observed, slowly

bleed the pressure and remove the gauge assembly.

Replace the pipe plug using a sealant. If the pressure

does not hold, then the leak must be located.

F-2) Impeller and Volute Service:

F-2.1) Disassembly and Inspection:

To clean out body (20), or to replace impeller (17),

disconnect power, remove hex bolts (21), and vertically lift

motor and seal assembly from body (20). Clean out body

if necessary . Clean and examine impeller (17) for pitting

or wear and replace if required. Inspect gasket (19) and

replace if cut or damaged. The impeller (17) is threaded

onto the shaft and to remove, unscrew impeller, holding

shaft with a large screwdriver. Remove exclusion seal (16)

and replace if needed.

F-2.2) Reassembly:

Before installing impeller (17), inspect threads on shaft

and impeller to assure that they are clean. Place exclu-

sion seal on shaft with the thin lip toward the motor (see

section F-4.3). Apply a thread-locking compound to shaft

threads and screw impeller onto shaft and tighten. Rotate

impeller to check for binding. Position gasket (19) on body

and install impeller and motor housing on pump body.

Apply thread locking compound to each cap screw (21),

thread into body, and torque to 11 ft. lbs. Check for free

rotation of impeller.

F-3) Motor, Bearing and Cable Service

F-3.1) Disassembly and Inspection:

BP & SE Series, Motor - To examine or replace the mo-

tor (1) or bearing (4), remove body and impeller as per

section F-2.1. Drain oil from motor housing as per section

F-1.2. Remove gland nut (9a) and friction ring (9b) from

motor housing (14). Pull cord through opening and discon-

nect the motor wires from the terminals on cable (9), see

Figure 5. Remove socket head screws (15) and lift motor

housing (14) from seal plate (2). Remove o-ring (13) and

inspect for breaks. Loosen motor screws and pull motor

(1) straight up and off seal plate (2). Inspect all parts for

signs of wear and check motor resistance values.

On “AU” series pumps gland nut (29a) and friction ring

(29b) must also be removed from motor housing (14) and

pulled though opening and motor wires from the terminals

on cable (2), see Figure 5.

BP-HT & SE-HT Series, Motor - To examine or replace

the motor (1) or bearing (4), remove body and impeller

as per section F-2.1. Drain oil from motor housing as

per section F-1.2. Remove socket head screws (15) and

loosen gland nut (9a) and push cord through while lifting

motor housing (14) off of seal plate (2). Disconnect motor

wires from cord set (9). Pull cord through motor housing

along with two friction rings and one gromment. (See

Figure 6). Remove o-ring (13) and inspect for breaks.

Loosen motor screws and pull motor (1) straight up and

off seal plate (2). Inspect all parts for signs of wear and

check motor resistance values.

On “HTAU” series pumps gland nut (29a), must also be

loosened from motor housing (14). Push cord through

while lifting motor housing (14) off of seal plate (2).

Disconnect motor wires from cord set (29). Pull cord

through motor housing along with friction rings (29b) and

grommet (29c), see Figure 6.

Check capacitor (7) with an Ohm meter by grounding the

capacitor by placing a screwdriver across both terminals

and then removing the screwdriver. Connect Ohm meter

(set on high scale) to terminals, if needle moves to infi nity

( ∞ ) then drifts back, the capacitor is good. If needle does

not move or moves to infi nity ( ∞ ) and does not drift back,

replace capacitor (7).

10 PSI

AIR

Pressure Gauge Assembly

(See Parts List)

Remove Pipe

Plug

FIGURE 4

Loading ...

Loading ...

Loading ...