Loading ...

Loading ...

Loading ...

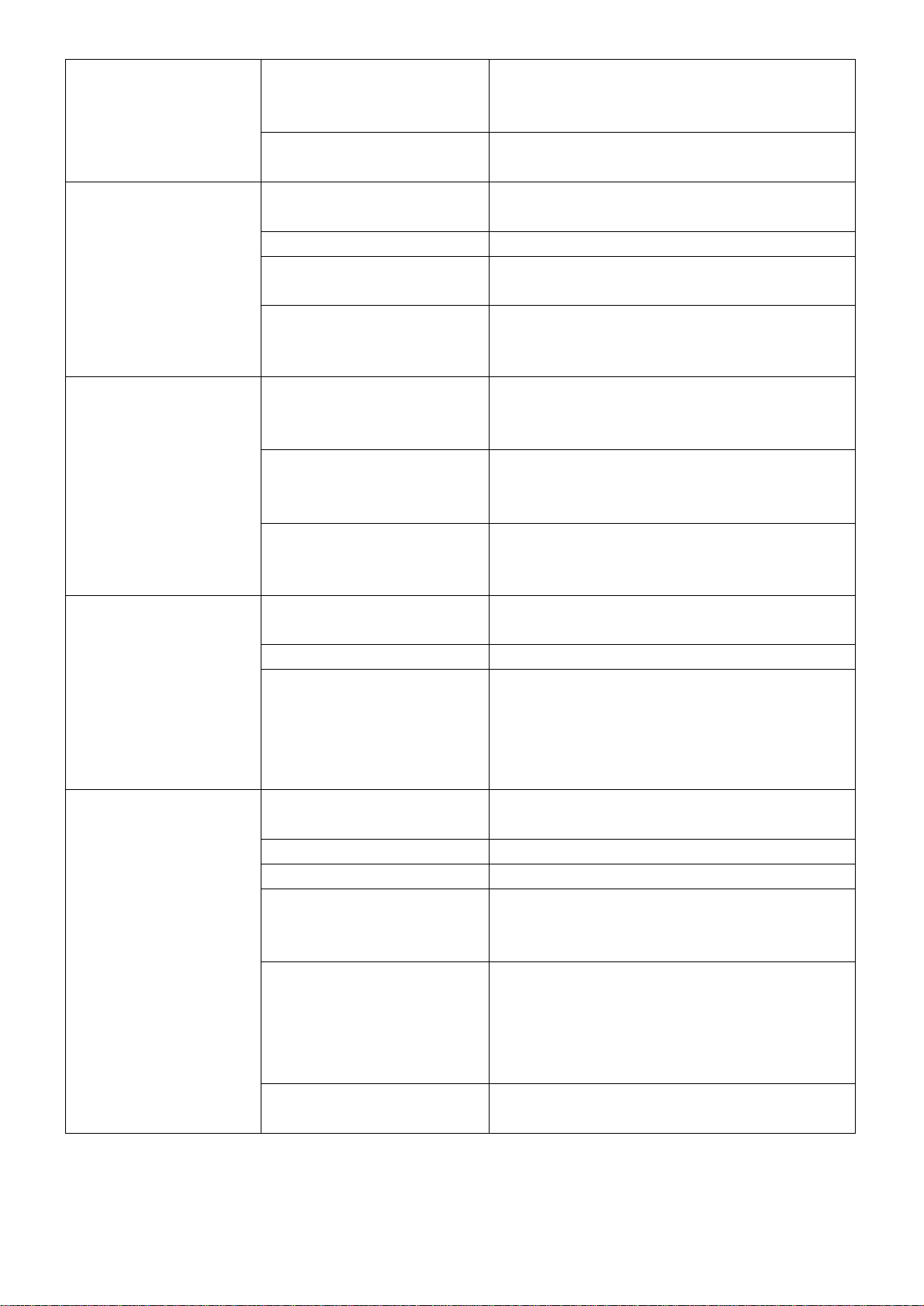

18

Needle valve is not

closed properly or start

hole is clogged.

Dismantle needle valve and repair, clean,

blow to get through.

supply.

Float is damaged or

sticking.

Repair float

Fuel is too filthy or

deteriorated

Replace

There is water in fuel Replace

Too much fuel in engine Drain extra fuel, dry up spark plug

electrodes

1. Normal cylinder

compression.

2. Normal spark plug

spark.

3. Something wrong

with the fuel

system.

4. Smooth fuel flow.

Wrong fuel brand Select proper fuel brand corresponding

with the requirements

Too much carbon deposit

and dirt around

electrodes.

Clear away

Electrodes are burn

damaged seriously or

insulators damaged

Replace spark plug

1. Normal cylinder

compression.

2. Normal fuel

supply.

3. Normal

high-pressure coil

spark.

4. Spark plug is in

bad conditions.

Improper electrodes gap Adjust to proper value

High-pressure coil is

damaged

Replace

Ignition coil is damaged Replace

1. Normal cylinder

compression.

2. Normal fuel

supply.

3. No high-pressure

coil spark.

4. Normal spark

plug.

Magneto loses

magnetism

Replace

Piston ring is worn to or

even over its wear limit

Replace

Piston ring is broken Replace

Piston ring is sticking Clear up carbon fouling

Spark plug is not installed

tighten or without a

gasket

Tighter with a gasket in

Air leakage between

cylinder block and

cylinder head

Check cylinder gasket, and the flatness of

the surface by which cylinder block

contacting with cylinder head, tighten

cylinder head bolts in stipulated order to

stipulated torque.

1. Poor cylinder

compression.

2. Normal fuel

supply system.

3. Normal ignition

system.

Air leakage in valves

Check valve, clearance and tightness,

repair if necessary

WARNING:

● When testing the spark plug, never hold the high-voltage wire of the spark plug with wet hand.

Loading ...

Loading ...

Loading ...