Loading ...

Loading ...

Loading ...

Westinghouse Outdoor Power Equipment, LLC | 15

MAINTENANCE

MAINTENANCE

MAINTENANCE SCHEDULE

Disconnect the spark plug boot from the spark plug

when performing maintenance on the pressure washer�

Regular maintenance will improve performance and extend

the service life of the pressure washer� Follow the hourly

or calendar intervals, whichever occurs rst. More frequent

service is required when operating in adverse conditions

as noted below�

Before Each Use

Check engine oil

Check water inlet screen and gasket

Clean around air intake and mufer

After First 5 Hours

Change engine oil

After 50 Hours or Every Season

Clean air lter

Change engine oil if operating under heavy load or in

hot environments

Clean spark arrestor

After 100 Hours or Every Season

Inspect/clean spark arrestor

Inspect/clean spark plug

Inspect/adjust valve clearance*

After 300 Hours

Replace spark plug

Replace air lter

* Recommend service to be performed by

authorized Westinghouse service dealer�

CLEANING THE PRESSURE WASHER

DO NOT spray the pressure washer with water� Water

can contaminate the fuel system and can enter the

engine through the cooling slots and damage the engine�

1. Use a damp cloth to clean exterior surfaces of the

pressure washer�

2. Use a soft bristle brush to remove dirt and oil�

3. Use an air compressor (25 PSI) to clear dirt and debris

from the pressure washer�

4. Inspect all air vents and cooling slots to ensure that they

are clean and unobstructed�

CLEANING SPRAY NOZZLES

Detach the nozzle from the spray lance� Use the included

nozzle cleaning tool to loosen any particles in the nozzle�

Flush with water�

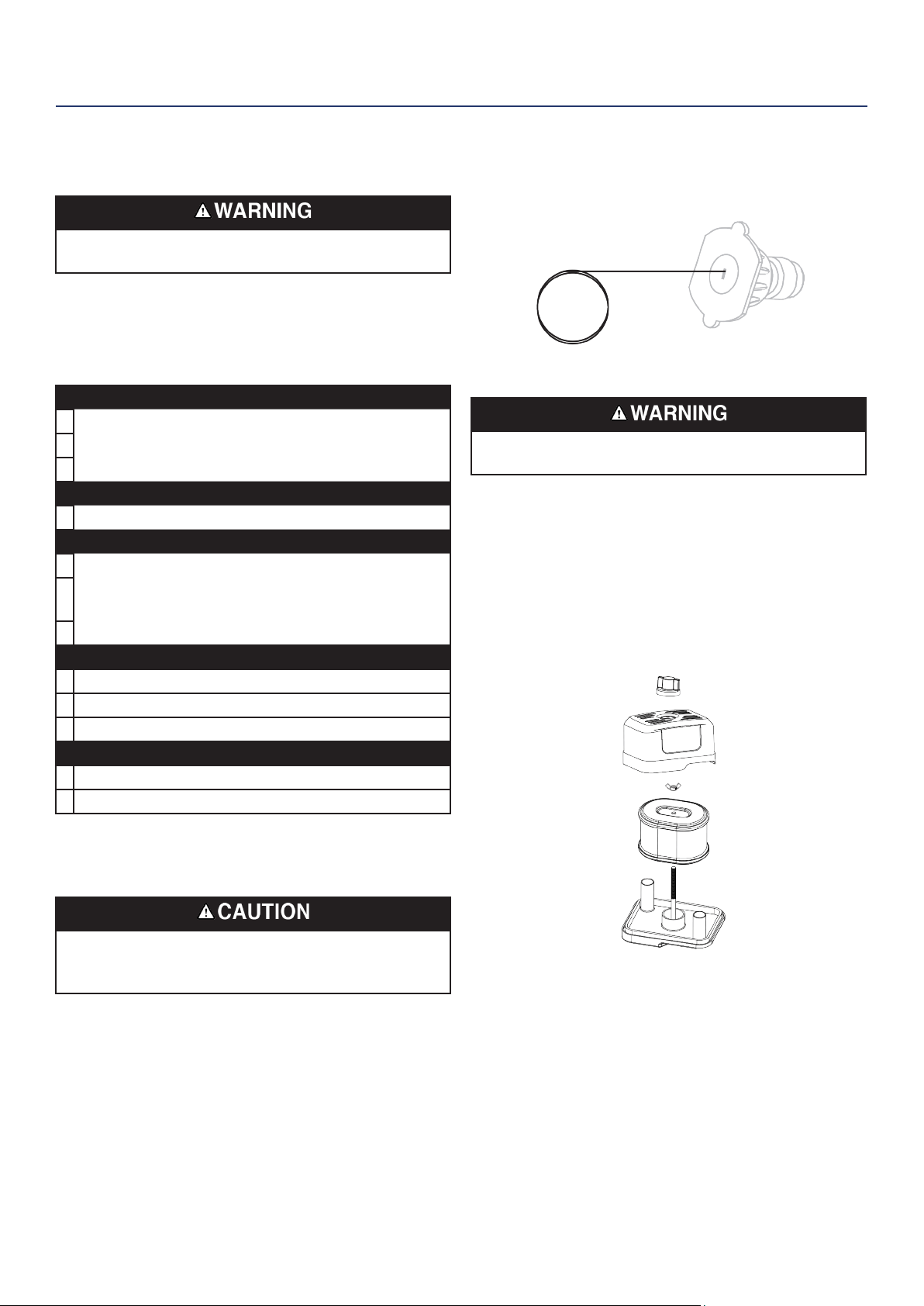

AIR FILTER MAINTENANCE

Fire hazard. Never use gasoline or other ammable

solvents to clean the air lter.

The air lter must be cleaned after every 50 hours of use or

six months (frequency should be increased if the pressure

washer is operated in a dusty environment)�

1. Place the pressure washer on a level surface and allow

the engine to cool for several minutes�

2. Use your ngers to unscrew the thumb screw on top

of the air lter assembly. Remove the wing nut, then

remove the air lter.

3. Use compressed air to clean the air lter from the inside

out�

Note: The outer foam air lter element is not intended to

be removed. If torn, replace the air lter.

Loading ...

Loading ...

Loading ...