Loading ...

Loading ...

Loading ...

5,)Correct Depth Gauges

a.); Place depth gauge tool over each cutter

• depth gauge. Figure 32,

b.) File level with the flat tile if depth gauge is

higher than the depth gauge tool,

c,) Maintain rounded front corner of depth

gauge with a fiat file. Figure 32&33.

NOT_: The very top of the depth gauge

shoutd be flat withthe front half-rounded -

' • off with a flat tile.

I & WARNING

Depth ga_e tool is required to insure proper depth

gauge. Fifi_he depth gauge too deep wilt increase

the chance Of kickback which-can result in serious

iniury.

b. CHAIN RIEPLACEMENT

1.) Use only the Low-Kick Chain specified for

_your saw in "Specifications" for replace.

.Z,::_:.ment chain.

_)_i;Reptace the chain when cutters or links

.... br_,ako

3.) See your Sears Service Center to replace

and sharpen individual cutters for match-

. ing your chain.

4.) Atwayshave a worn sprocket replaced by

...... y0urSearsServiceCenterwheninstalling

a new chain to.avoid excessivewear to the

chain.

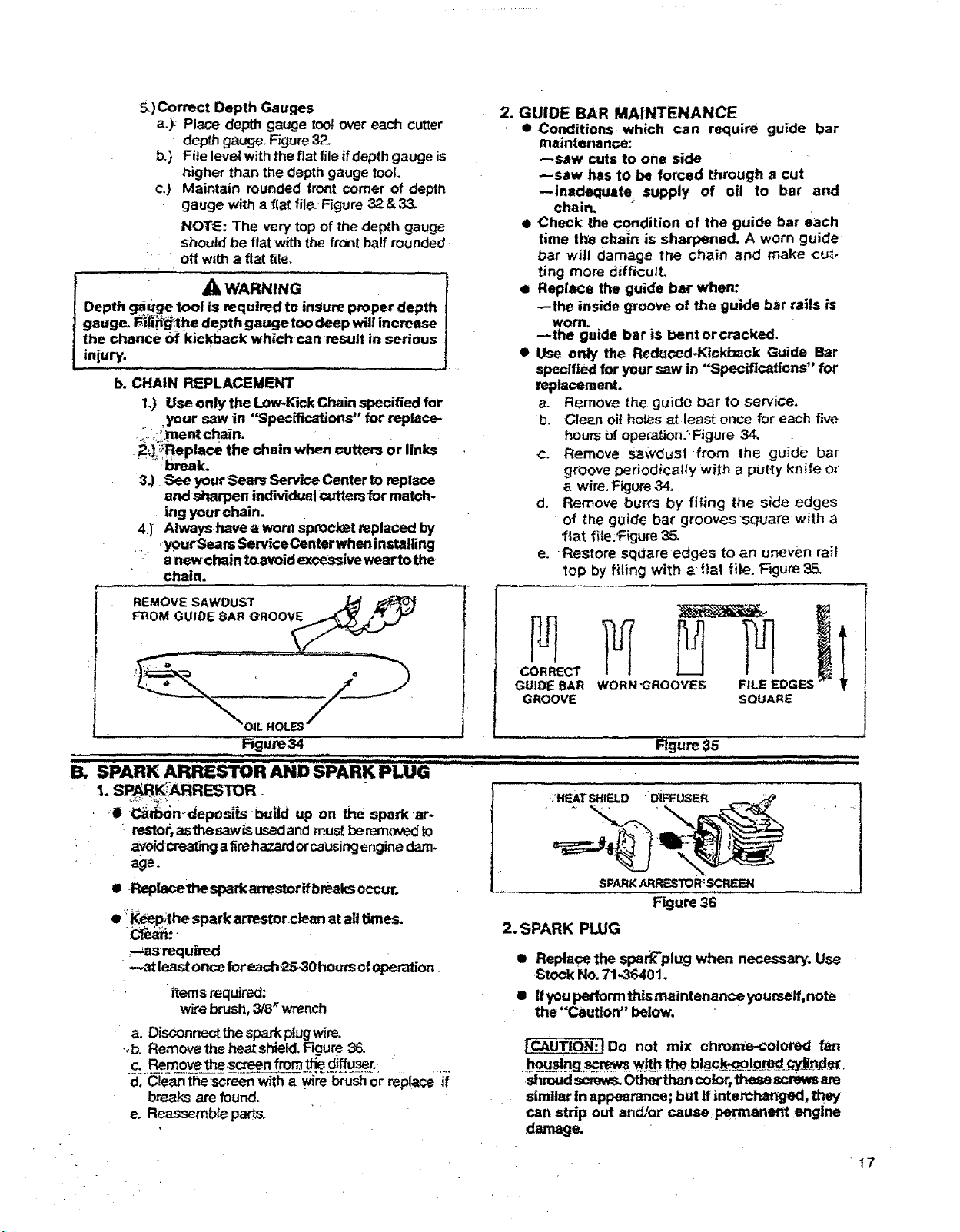

REMOVE SAWDUST

FROM GUIDE BAR GROOVE

2. GUIDE BAR MAINTENANCE

• Conditions which can require guide bar

maintenance:

_saw cuts to one side

--saw has to be forced through a cut

--inadequate supply of oil to bar and

chain,

• Check the condition of the guide bar each

time the chain is sharpened. A worn guide

bar will damage the chain and make cut-

ting more difficult.

• Replace the guide bar when:

--the inside groove of the guide bar rails is

WON'I.

--the guide bar is bent 0rcracked.

• Use only the ReducedJ<ickback Guide Bar

specified for your saw in "Specifications" for

replacement.

a. Remove the guide bar to Service.

b. Clean oil-holes at least once for each five

hours Of operation:Figure 34,

c. Remove Sawdust from the guide bar

groove periodically witt_ a putty knife or

a wire, Figure 34,

d. Remove buKs by filing the side edges

of the guide bar grooves square with a

'flat fi-le:Figure 35.

e. Restore eqUateedges to an uneven rai!

top by filing with a tlal file. F_jure 35.

CORRECT

GUIDE BAR WORN-GROOVES FILE EDGES

GROOVE SQUARE

OIfL HOLES

13. SPARK ARRESTOR AND SPARK PLUG

: -dep s ts bu.duponthe sparkar-

. ' restor, aslhesawisusedand must be removed to

avoid creating afire hazard orcausing engine dam-

age.

• Rep_v_ethesparkarrestorifbre.aks occur.

• __l?;the spark arrestor.clean at alt times.

.C]_:-

Rgure 35

sp K ............

Figure 36

2. SPARK PLUG

_--_asrequired

--at least once foreach,25-30 hours of operation.

items required:

wire brush, 3/8 _wrench

a. Disconnect the spark plug wire.

-,b. Removethe heatshield. Figure 36.

.c: ..Een_ore i:__. o'eenS__m._e .d.iff.u_.F: _

d, Clean the screen with a ._re brush or replace it

breaks are found.

e. Reassemb_ parts.

• Replace the spark-plug when necessary. Use

Stock No, 71_6401.

I Ifyou perform thts maintenance yourself, note

the "Caution" below.

|CAUTION:IDo not mix chrome-colored fan

ho__sln_g.._...W.._ ._tf:_...b..!.a.c__l_=_qy_l_der.

.shroud screws.Otherthan color,thesescrewsare

similar In appearance; but If interchanged, they

can strip out andJor cause, permanent engine

damage.

17

Loading ...

Loading ...

Loading ...