Documents: Go to download!

User Manual

- Owner's manual - (English)

- Sizing Guide - (English)

- Warranty - (English)

- RANGE MAINTENANCE AND CARE

- INSTALLATION INSTRUCTIONS REQUIREMENTS

Table of contents

User Manual

RANGE MAINTENANCE AND CARE

Self-Cleaning Cycle (on some models)

IMPORTANT: The health of some birds is extremely sensitive to the fumes given off during the Self-Cleaning cycle. Exposure to the fumes may result in death to certain birds. Always move birds to another closed and well-ventilated room.

Keep the kitchen well-ventilated during the Self-Cleaning cycle to help get rid of heat, odors, and smoke.

Do not block the oven vent(s) during the Self-Cleaning cycle. Air must be able to move freely. Depending on your model, see the “Oven Vent” or “Oven Vents” section.

Do not clean, rub, damage, or move the oven door gasket.

Prepare Range:

- Remove the broiler pan, grid, cookware and bakeware, all cooking utensils, oven racks, aluminum foil, and, on some models, the temperature probe from the oven.

- Use a damp cloth to clean inside door edge and the 1&1/2" (38 mm) area around the inside oven cavity frame, being certain not to move or bend the gasket.

- Remove plastic items from the cooktop because they may melt.

- Remove all items from the storage drawer.

How the Cycle Works

IMPORTANT: The heating and cooling of porcelain on steel in the oven may result in discoloring, loss of gloss, hairline cracks, and popping sounds.

Before self-cleaning, make sure the door is completely closed or the door will not lock and the Self-Cleaning cycle will not begin.

Once the oven has completely cooled, remove ash with a damp cloth. To avoid breaking the glass, do not apply a cool damp cloth to the inner door glass before it has completely cooled.

To stop the Self-Cleaning cycle at any time, press CANCEL or OFF/CANCEL. If the temperature is too high, the oven door will remain locked and “cool” and “locked ” or “ ” will be displayed. The cooling fan may continue to run. The oven light will not function during the Self-Cleaning cycle.

” will be displayed. The cooling fan may continue to run. The oven light will not function during the Self-Cleaning cycle.

Electronic Oven Control with Adjustable Clean Time (on some models)

The Self-Cleaning cycle is time adjustable between 2 hours 30 minutes and 4 hours 30 minutes in 30-minute increments. Suggested clean times are 2 hours 30 minutes for light soil and 4 hours 30 minutes for heavy soil.

IMPORTANT: When cooktop is in use, the Self-Cleaning cycle will be disabled. When the Self-Cleaning cycle is in use, the cooktop will be locked.

To Self-Clean:

- Press SELF CLEAN.

- Press the Temp/Time up or down arrow keypad to enter the desired Self-Cleaning cycle time.

- Press START. The oven door will automatically lock. The Door Locked and Clean indicator lights will be displayed. The time remaining will also be displayed.

- When the Self-Cleaning cycle is complete and the oven cools, the Door Locked and Clean indicator lights will turn off.

- When the oven is completely cooled, remove ash with a damp cloth.

To exit the Self-Cleaning cycle before completed, press CANCEL or OFF/CANCEL. The door will unlock once the oven cools.

General Cleaning

EXTERIOR PORCELAIN ENAMEL SURFACES (on some models)

Food spills containing acids, such as vinegar and tomato, should be cleaned as soon as the entire range is cool. These spills may affect the finish.

Cleaning Method:

- Glass cleaner, mild liquid cleaner, or nonabrasive scrubbing pad: Gently clean around the model/serial/rating plate because scrubbing may remove numbers.

- affresh® Kitchen and Appliance Cleaner Part Number W10355010 (not included):See the “Accessories” section for more information.

STAINLESS STEEL (on some models)

NOTE: To avoid damage to stainless steel surfaces, do not use soap-filled scouring pads, abrasive cleaners, Cooktop Cleaner, steel-wool pads, gritty washcloths, or abrasive paper towels.

Damage may occur to stainless steel surfaces, even with one-time or limited use.

Cleaning Method:

- Rub in direction of grain to avoid damaging. affresh® Stainless Steel Cleaner Part Number W10355016 (not included):See the “Accessories” section for more information.

METALLIC PAINT (on some models)

Do not use abrasive cleaners, cleaners with bleach, rust removers, ammonia, or sodium hydroxide (lye) because the paint surface may stain.

CERAMIC GLASS (on some models)

To avoid damaging the cooktop, do not use steel wool, abrasive powder cleansers, chlorine bleach, rust remover, or ammonia.

1. Remove food/residue with the Cooktop Scraper.

- For best results, use the Cooktop Scraper while the cooktop is still warm but not hot to the touch. It is recommended to wear an oven mitt while scraping the warm cooktop.

- Hold the Cooktop Scraper at approximately a 45° angle against the glass surface and scrape the residue. It will be necessary to apply pressure in order to remove the residue.

Allow the cooktop to cool down completely before proceeding to Step 2.

2. Apply a few dime-sized drops of affresh® Cooktop Cleaner to the affected areas.

- Rub affresh® Cooktop Cleaner onto the cooktop surface with the blue Cooktop Cleaning Pad. Some pressure is needed to remove stubborn stains.

- Allow the cleaner to dry to a white haze before proceeding to Step 3.

3. Polish with a clean, dry cloth or a clean, dry paper towel.

- Repeat steps 1 through 3 as necessary for stubborn or burned-on stains.

The Complete Cooktop Cleaner Kit is available for order including the following:

- Cooktop Scraper

- affresh® Cooktop Cleaner

- Blue Cooktop Cleaning Pads

See the “Accessories” section for part numbers and information on ordering.

COOKTOP CONTROLS

To avoid damage to the cooktop controls, do not use steel wool, abrasive cleansers, or oven cleaner.

To avoid damage, do not soak knobs. When replacing knobs, make sure knobs are in the Off position.

On some models, do not remove seals under knobs.

Cleaning Method:

- Soap and water: Pull knobs straight away from control panel to remove.

CONTROL PANEL AND OVEN DOOR EXTERIOR

To avoid damage to the control panel, do not use abrasive cleaners, steel-wool pads, gritty washcloths, or abrasive paper towels.

Cleaning Method:

- Glass cleaner and soft cloth or sponge:

- Apply glass cleaner to soft cloth or sponge, not directly on panel. affresh® Kitchen and Appliance Cleaner Part Number W10355010 (not included):See the “Accessories” section for more information.

OVEN RACKS

Cleaning Method:

- Steel-wool pad

- For racks that have discolored and are harder to slide, a light coating of vegetable oil applied to the rack guides will help them slide.

STORAGE DRAWER (on some models)

Check that storage drawer is cool and empty before cleaning.

Cleaning Method:

- Mild detergent

OVEN CAVITY

Use AquaLift® Technology regularly to clean oven spills.

Do not use oven cleaners.

Food spills should be cleaned when oven cools. At high temperatures, foods react with porcelain. Staining, etching, pitting, or faint white spots can result.

Cleaning Method:

- Clean cycle:See the “Clean Cycle” section.

INSTALLATION INSTRUCTIONS REQUIREMENTS

Location Requirements

IMPORTANT: Observe all governing codes and ordinances.

- It is the installer's responsibility to comply with installation clearances specified on the model/serial/rating plate. The model/serial/rating plate is located behind the oven door on the top right-hand side of the oven frame.

- The range should be located for convenient use in the kitchen.

- Recessed installations must provide complete enclosure of the sides and rear of the range.

- All openings in the wall or floor where range is to be installed must be sealed.

- Cabinet opening dimensions that are shown must be used. Given dimensions are minimum clearances.

- The anti-tip bracket must be installed. To install the anti-tip bracket shipped with the range, see the “Install Anti-Tip Bracket” section.

- Grounded electrical supply is required. See the appropriate “Electrical Requirements” section.

- Contact a qualified floor covering installer to check that the floor covering can withstand at least 200°F (93°C).

- Use an insulated pad or 1/4" (0.64 cm) plywood under range if installing range over carpeting.

IMPORTANT: To avoid damage to your cabinets, check with your builder or cabinet supplier to make sure that the materials used will not discolor, delaminate or sustain other damage. This oven has been designed in accordance with the requirements of UL and CSA International and complies with the maximum allowable wood cabinet temperatures of 194°F (90°C).

Mobile Home - Additional Installation Requirements

The installation of this range must conform to the Manufactured Home Construction and Safety Standard, Title 24 CFR, Part 3280 (formerly the Federal Standard for Mobile Home Construction and Safety, Title 24, HUD Part 280). When such standard is not applicable, use the Standard for Manufactured Home Installations, ANSI A225.1/NFPA 501A or with local codes.

In Canada, the installation of this range must conform with the current standards CAN/CSA-Z240.1-latest edition, or with local codes.

Mobile home installations require:

- When this range is installed in a mobile home, it must be secured according to the instructions in this document.

- Four-wire power supply cord or cable must be used in a mobile home installation. The appliance wiring will need to be revised. See “Electrical Connection - U.S.A. Only” section.

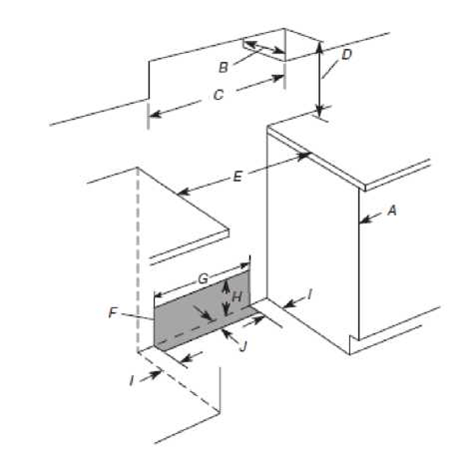

Cabinet Dimensions

Cabinet opening dimensions shown are for 25" (64.0 cm) countertop depth, 24" (61.0 cm) base cabinet depth, and 36" (91.4 cm) countertop height.

IMPORTANT: If installing a range hood or microwave hood combination above the range, follow the range hood or microwave hood combination installation instructions for dimensional clearances above the cooktop surface.

Range may be installed next to combustible walls with zero clearance.

A. Cabinet door or hinges should not extend into the cutout.

B. 13" (33 cm) max. upper cabinet depth

C. 30" (76.2 cm) min. opening width

D. For minimum clearance to top of cooktop, see NOTE*.

E. 30" (76.2 cm) min. opening width

F. The shaded area is recommended for installation of grounded outlet.

G. 131/8" (33.3 cm)

H. 711/86" (19.5 cm)

I. 413/i6" (12.2 cm)

J. 311/16" (9.4 cm)

*NOTE: 24" (61.0 cm) minimum when bottom of wood or metal cabinet is shielded by not less than 1/4" (0.64 cm) flame retardant millboard covered with not less than No. 28 MSG sheet steel,

0.015" (0.4 mm) stainless steel, 0.024" (0.6 mm) aluminum or

0.020" (0.5 mm) copper.

30" (76.2 cm) minimum clearance between the top of the cooking platform and the bottom of an uncovered wood or metal cabinet.

INSTALLATION Unpack Range

1. Remove shipping materials, tape and film from the range. Keep cardboard bottom under range. Do not dispose of anything until the installation is complete.

2. Remove oven racks and parts package from oven and shipping materials.

3. To remove cardboard bottom, first take 4 cardboard corners from the carton. Stack one cardboard corner on top of another. Repeat with the other 2 corners. Place them lengthwise on the floor behind the range to support the range when it is laid on its back.

4. Using 2 or more people, firmly grasp the range and gently lay it on its back on the cardboard corners.

5. Remove cardboard bottom.

The leveling legs can be adjusted while the range is on its back. See the “Adjust Leveling Legs” section.

NOTE: To place range back up into a standing position, put a sheet of cardboard or hardboard on the floor in front of range to protect the flooring. Using 2 or more people, stand range back up onto the cardboard or hardboard.

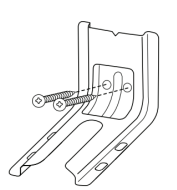

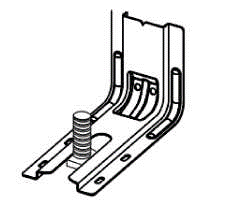

Install Anti-Tip Bracket

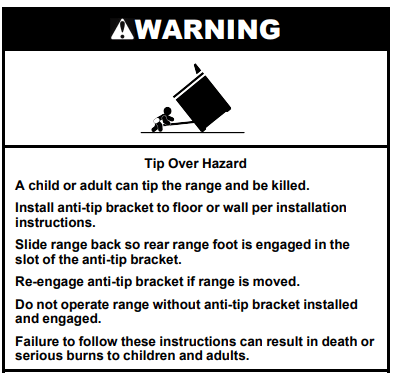

A child or adult can tip the range and be killed.

Install anti-tip bracket to floor or wall per installation instructions.

Slide range back so rear range foot is engaged in the slot of the anti-tip bracket.

Re-engage anti-tip bracket if range is moved.

Do not operate range without anti-tip bracket installed and engaged.

Failure to follow these instructions can result in death or serious burns to children and adults.

- Remove the anti-tip bracket from the inside of the oven.

- Determine which mounting method to use: floor or wall.

If you have a stone or masonry floor, you can use the wall mounting method. If you are installing the range in a mobile home, you must secure the range to the floor.

This anti-tip bracket and screws can be used with wood or metal studs.

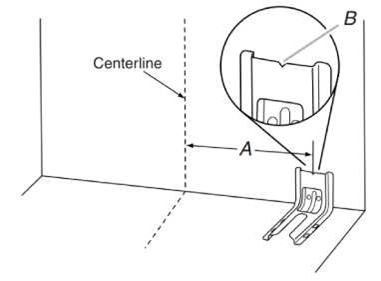

3. Determine and mark centerline of the cutout space. The

mounting can be installed on either the left-side or right-side of the cutout. Position mounting bracket against the wall in the cutout so that the V-notch of the bracket is 121/2" (31.8 cm) from centerline as shown.

A. 121/2" (31.8 cm)

B. Bracket V-notch

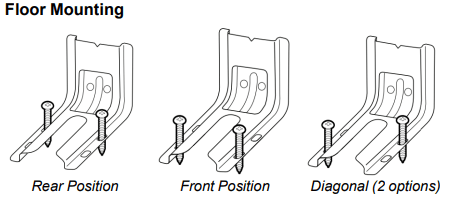

4. Drill two 1/8" (3 mm) holes that correspond to the bracket holes of the determined mounting method. See the following illustrations.

Wall Mounting

5. Using the two #10 x 15/s" (4.1 cm) Phillips-head screws provided, mount anti-tip bracket to the wall or floor.

6. Move range close enough to opening to allow for final electrical connections. Remove shipping base, cardboard or hardboard from under range.

7. Move range into its final location, making sure rear leveling leg slides into anti-tip bracket.

8. Move range forward onto shipping base, cardboard or hardboard to continue installing the range using the following installation instructions.

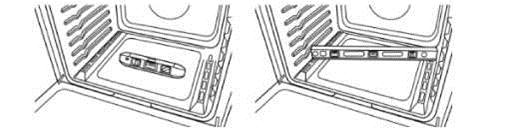

Level Range

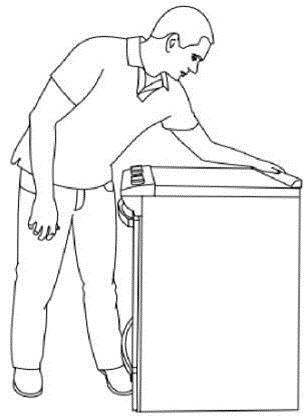

1. Place level on the oven bottom, as indicated in one of the two figures below, depending on the size of the level. Check with the level side to side and front to back.

2. If range is not level, use a wrench or pliers to adjust leveling legs up or down until the range is level.

NOTE: Range must be level for satisfactory baking performance and best cleaning results using AquaLift® SelfClean Technology.

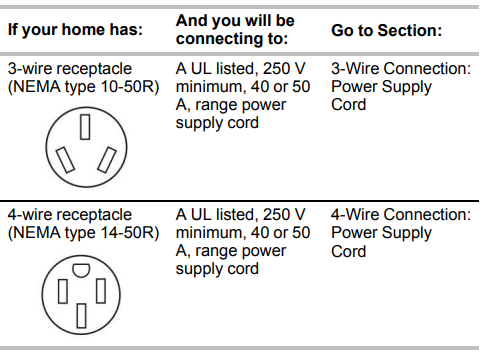

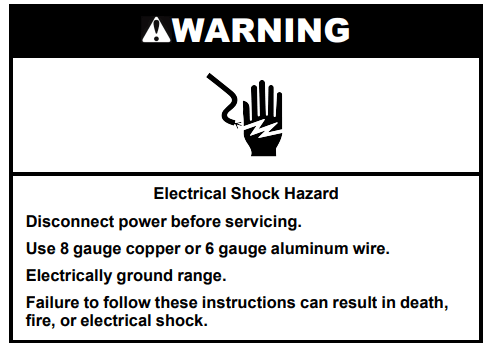

Electrical Connection - U.S.A. Only

If your home has a 3- or 4-wire receptacle, continue with “Install Using a Power Supply Cord.” If your home has a 3- or 4-wire direct connection, go to “Install Using Direct Wire.”

Install Using a Power Supply Cord

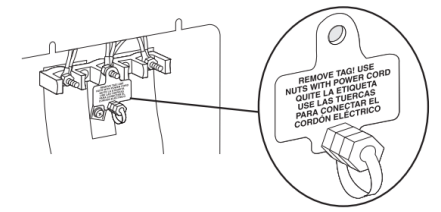

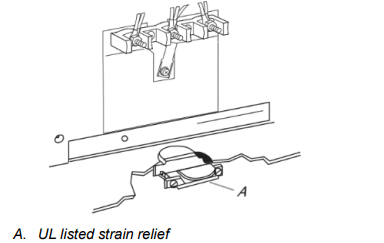

Power Supply Cord Strain Relief

1. Disconnect power.

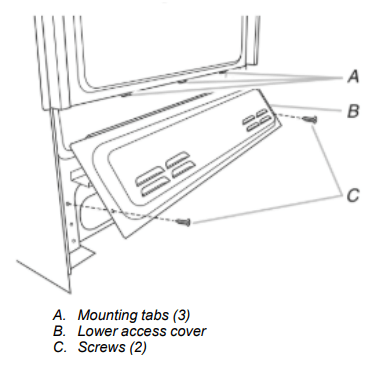

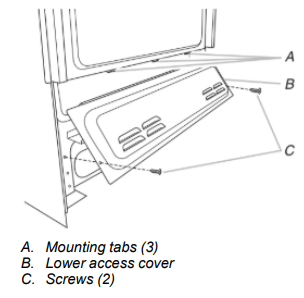

2.Remove the lower access cover screws located on the back of the range. Pull the bottom of the cover toward you and out to remove cover from range.

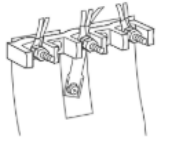

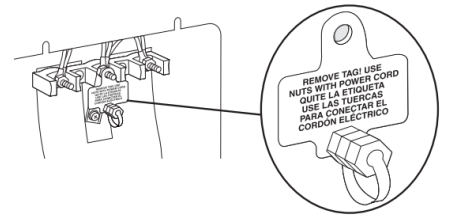

3. Remove plastic tag holding three 10-32 hex nuts from the middle post of the terminal block.

OR

Remove the top 10-32 hex nut from each of the 3 terminal blocks and set aside.

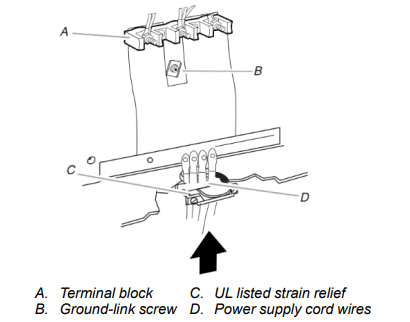

4. Assemble a UL listed strain relief in the opening.

5. Complete installation following instructions for your type of electrical connection:

4-wire (recommended)

3-wire (if 4-wire is not available)

Electrical Connection Options

4-Wire Connection: Power Supply Cord

Use this method for:

- New branch-circuit installations (1996 NEC)

- Mobile homes

- Recreational vehicles

- In an area where local codes prohibit grounding through the neutral

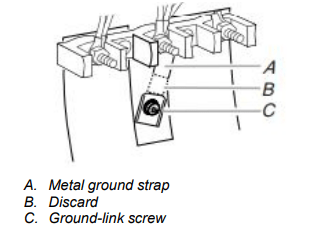

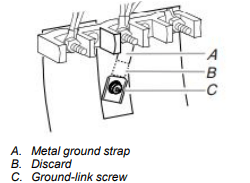

1. Part of metal ground strap must be cut out and removed.

2. Use a Phillips screwdriver to remove the ground-link screw from the back of the range. Save the ground-link screw and the end of the ground link under the screw.

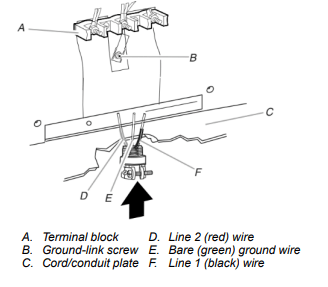

3. Feed the power supply cord through the strain relief on the cord/conduit plate on bottom of range. Allow enough slack to easily attach the wiring to the terminal block.

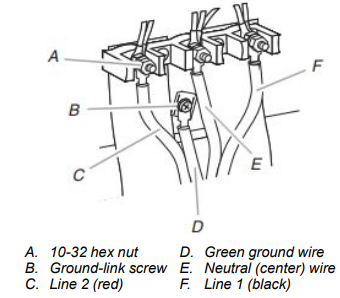

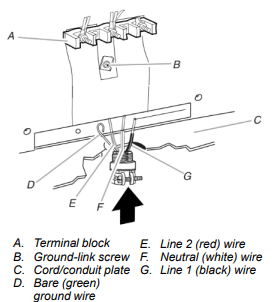

4. Use Phillips screwdriver to connect the green ground wire from the power supply cord to the range with the ground-link screw. The ground wire must be attached first.

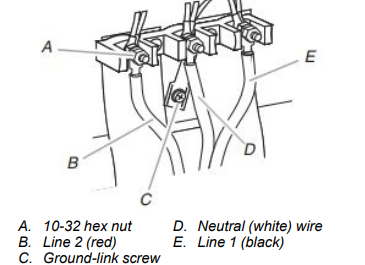

5. Use 3/8" (9.5 mm) nut driver to connect the neutral (white) wire to the center terminal block post with one of the 10-32 hex nuts.

6. Connect line 2 (red) and line 1 (black) wires to the outer terminal block posts with 10-32 hex nuts.

7. Securely tighten hex nuts.

NOTE: For power supply cord replacement, use only a power cord rated at 250 V minimum, 40 A or 50 A that is marked for use with nominal 1%" (3.5 cm) diameter connection opening, with ring terminals and marked for use with ranges.

8. Tighten strain relief screws.

9. Replace terminal block access cover.

3-Wire Connection: Power Supply Cord

Use this method only if local codes permit connecting chassis

ground conductor to neutral wire of power supply cord.

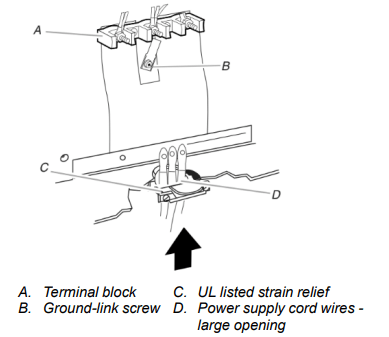

1. Feed the power supply cord through the strain relief in the cord/conduit plate on bottom of range. Allow enough slack to easily attach the wiring to the terminal block.

2. Use 3/8" (9.5 mm) nut driver to connect the neutral (white) wire to the center terminal block post with one of the 10-32 hex nuts.

3. Connect line 2 (red) and line 1 (black) wires to the outer terminal block posts with 10-32 hex nuts.

4. Securely tighten hex nuts.

NOTE: For power supply cord replacement, only use a power cord rated at 250 V minimum, 40 A or 50 A that is marked for use with nominal 13/s" (3.5 cm) diameter connection opening, with ring terminals and marked for use with ranges.

5. Tighten strain relief screws.

IMPORTANT: Verify the tightness of the hex nuts.

6. Replace terminal block access cover.

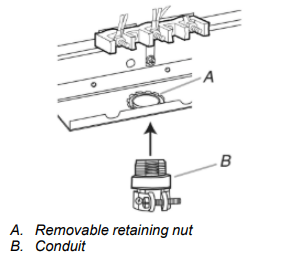

Install Using Direct Wire

Direct Wire Strain Relief

1. Disconnect power.

2. Remove the lower access cover screws located on the back of the range. Pull the bottom of the cover toward you and out to remove cover from range.

3. Remove plastic tag holding three 10-32 hex nuts from the middle post of the terminal block.

OR

Remove the top 10-32 hex nut from each of the 3 terminal blocks and set aside.

4. Assemble a UL listed conduit connector in the opening.

5. Tighten strain relief screw against the flexible conduit.

4-Wire Connection: Direct Wire

Use this method for:

- New branch-circuit installations (1996 NEC)

- Mobile homes

- Recreational vehicles

- In an area where local codes prohibit grounding through the neutral

1. Part of metal ground strap must be cut out and removed.

2. Use a Phillips screwdriver to remove the ground-link screw from the back of the range. Save the ground-link screw and the end of the ground link under the screw.

3. Pull the wires through the strain relief on bottom of range. Allow enough slack to easily attach wiring to the terminal block.

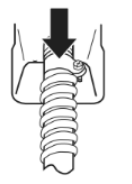

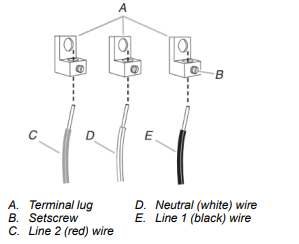

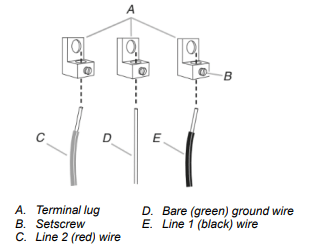

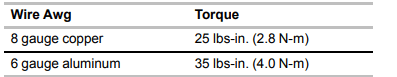

4. Attach terminal lugs to line 1 (black), neutral (white), and line 2 (red) wires. Loosen (do not remove) the setscrew on the front of the terminal lug and insert exposed wire end through bottom of terminal lugs. Securely tighten setscrew to torque as shown in the following Bare Wire Torque Specifications chart.

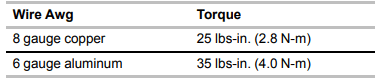

Bare Wire Torque Specifications

Attaching terminal lugs to the terminal block - 20 lbs-in. (2.3 Nm)

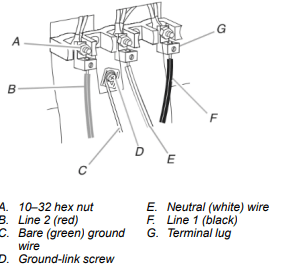

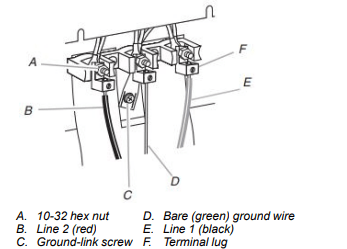

5. Use a hex or Phillips screwdriver to connect the bare (green) ground wire to the range with the ground-link screw and ground-link section. The ground wire must be attached first and must not contact any other terminal.

6. Use 3/8" nut driver to connect the neutral (white) wire to the center terminal block post with one of the 10–32 hex nuts.

7. Connect line 2 (red) and line 1 (black) wires to the outer terminal block posts with 10-32 hex nuts.

8. Securely tighten hex nuts.

9. Replace terminal block access cover

3-Wire Connection: Direct Wire

Use this method only if local codes permit connecting ground

conductor to neutral supply wire.

1. Pull the wires through the conduit on cord/conduit plate on bottom of range. Allow enough slack to easily attach the wiring to the terminal block.

2. Attach terminal lugs to line 2 (red), bare (green) ground, and line 1 (black) wires. Loosen (do not remove) the setscrew on the front of the terminal lug and insert exposed wire end through bottom of terminal lugs. Securely tighten setscrew to torque as shown in the following Bare Wire Torque Specifications chart.

Bare Wire Torque Specifications

Attaching terminal lugs to the terminal block - 20 lbs-in. (2.3 Nm)

3. Use 3/8" nut driver to connect the bare (green) ground wire to the center terminal block post with one of the 10–32 hex nuts.

4. Connect line 2 (red) and line 1 (black) wires to the outer terminal block posts with 10-32 hex nuts.

5. Securely tighten hex nuts.

6. Replace terminal block access cover.

Verify Anti-Tip Bracket Is Installed and Engaged

On Ranges Equipped with a Premium Storage Drawer:

1. Slide range into final location, making sure rear leveling leg slides into anti-tip bracket.

2. Remove the premium storage drawer. See the “Remove/ Replace Drawer” section.

3. Use a flashlight to look underneath the bottom of the range.

4. Visually check that the rear range foot is inserted into the slot of the anti-tip bracket.

On Ranges Equipped with a Warming Drawer or Baking Drawer:

1. Slide range into final location, making sure rear leveling leg slides into anti-tip bracket. Leave a 1" (2.5 cm) gap between the back of the range and the back wall.

2. Place the outside of your foot against the bottom front of the warming drawer or baking drawer to keep the range from moving, and then grasp the back of the range as shown.

3. Slowly attempt to tilt the range forward.

If you encounter immediate resistance, the range foot is engaged in the anti-tip bracket. Go to Step 8.

4. If the rear of the range lifts more than 1/2" (1.3 cm) off the floor without resistance, stop tilting the range and lower it gently back to the floor. The range foot is not engaged in the anti-tip bracket.

IMPORTANT: If there is a snapping or popping sound when lifting the range, the range may not be fully engaged in the bracket. Check to see if there are obstructions keeping the range from sliding to the wall or keeping the range foot from sliding into the bracket. Verify that the bracket is held securely in place by the mounting screws.

5. Slide the range forward, and verify that the anti-tip bracket is securely attached to the floor or wall.

6. Slide range back so the rear range foot is inserted into the slot of the anti-tip bracket.

7. Repeat steps 1 and 2 to ensure that the range foot is engaged in the anti-tip bracket.

If the rear of the range lifts more than 1/2" (1.3 cm) off the floor without resistance, the anti-tip bracket may not be installed correctly. Do not operate the range without anti-tip bracket installed and engaged. Please reference the Quick Start Guide for contact information.

8. Move the range into its final location. Check that the range is level by placing a level on the oven bottom. See the “Level Range” section.

IMPORTANT: If the range is moved to adjust the leveling legs, verify that the anti-tip bracket is engaged by repeating steps 1 to 8.

Remove/Replace Drawer

Remove all items from inside the baking drawer, warming drawer or premium storage drawer, and then allow the range to cool completely before attempting to remove the drawer

To Remove:

1. Open the drawer to its fully open position.

2. Raise the front edge, and then lift out.

To Replace:

1. Align the forward drawer notches with the notches in the drawer rails on both sides. Place the rear alignment tabs into the drawer rails on both sides.

2. Push the drawer in all the way.

3. Gently open and close the drawer to ensure it is seated properly on the rails on both sides.

Oven Door

For normal range use, it is not suggested to remove the oven door. However, if removal is necessary, make sure the oven is off and cool. Then, follow these instructions. The oven door is heavy.

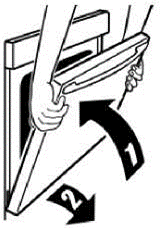

To Remove:

1. Open oven door all the way.

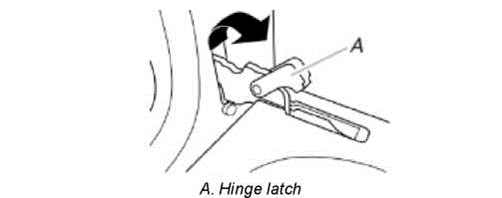

2. Pinch the hinge latch between two fingers and pull forward. Repeat on other side of oven door.

3. Close the oven door as far as it will shut.

4. Lift the oven door while holding both sides.

Continue to push the oven door closed and pull it away from the oven door frame.

To Replace:

1. Insert both hanger arms into the door. Be sure that the hinge notches are engaged in the oven door frame.

2. Open the oven door.

The door should be able to open all the way.

3. Move the hinge levers back to the locked position. Check that the door is free to open and close and is level while closed. If it is not, repeat the removal and installation procedures.

Complete Installation

- Check that all parts are now installed. If there is an extra part, go back through the steps to see which step was skipped.

- Check that you have all of your tools.

- Check that you have all of the range accessories, especially oven racks. These accessories may be in the range packaging.

- Dispose of/recycle all packaging materials.

- Check that the range is level. See the “Level Range” section.

- Use a mild solution of liquid household cleaner and warm water to remove waxy residue caused by shipping material. Dry thoroughly with a soft cloth. For more information, see the “Range Maintenance and Care” section.

- Read the Quick Start Guide and online Control Guide.

- Plug power cord into appropriate outlet. Turn power on.

- Turn on surface burners and oven. See the Quick Start Guide and online Control Guide for specific instructions on range operation.

NOTE: Odors and smoke are normal when the oven is used the first few times.

If Range Does Not Operate, Check the Following:

- Household fuse is intact and tight; or circuit breaker has not tripped.

- Range is plugged into a grounded outlet.

- Electrical supply is connected.

IMPORTANT: If the range control displays an “F9” or “F9, E0” error code, the electrical outlet in the home may be miswired. Disconnect power and contact a qualified electrician to verify the electrical supply.

10. When the range has been on for 5 minutes, check for heat. If the range is cold, turn off the range and contact a qualified electrician.

If You Need Assistance or Service:

Please reference the Quick Start Guide for contact information.

Moving the Range

When moving range, slide range onto cardboard or hardboard to avoid damaging the floor covering.

If removing the range is necessary for cleaning or maintenance:

For power supply cord-connected ranges:

- Slide range forward.

- Unplug the power supply cord.

- Complete cleaning or maintenance.

- Plug in power supply cord.

- Check that the anti-tip bracket is installed and engaged. See the “Verify Anti-Tip Bracket Is Installed and Engaged” section.

- Check that range is level.

For direct-wired ranges:

- Disconnect power.

- Slide range forward.

- Complete cleaning or maintenance.

- Check that the anti-tip bracket is installed and engaged. See the “Verify Anti-Tip Bracket Is Installed and Engaged” section.

- Check that range is level.

- Reconnect power.

See other models: WEE745H0LZ WFE535S0LS WFE550S0LZ WED5010LW WGD5010LW