Loading ...

Loading ...

Loading ...

21

GAS SUPPLY AND GAS PIPING SIZE

• Check that the type of gas matches the rating plate rst.

• Ensure that any and all gas regulators are operating properly and

providing gas pressures withing the specied range shown below.

Excess gas inlet pressure may cause serious accidents.

• Conversion of this unit from natural gas to propane or vice versa will void all

warranty. Contact your local distributor to get the correct unit for your gas

type. The manufacturer is not liable for nay property and/or personal

damage resulting from gas conversions.

• The minimum and maximum inlet gas pressures are:

• Inlet gas pressures that fall outside the range of values listed above may adversely affect the per-

formance of the micro boiler. These pressures are measured when the micro boiler is in full opera-

tion.

• Inlet gas pressure must not exceed the above maximum values; gas pressure above the specied

range will cause dangerous operating conditions a damages to the unit.

• Until testing of the main gas line supply pressure is completed, ensure the gas line to the micro

boiler is disconnected to avoid any further damage.

Gas connections

1. Install a manual gas shutoff valve between the micro boiler and the gas supply.

2. When the gas connections are completed, it is necessary to perform a gas leak test either by

applying soapy water to all gas ttings and observing for bubble or by using a gas leak detection

device.

• The micro boiler and its individual shutoff valve must be disconnected from the gas supply pip-

ing system during any pressure testing of that system at the test pressures in excess of 1/2 psi

(3.5kPa).

• The micro boiler must be isolated from the gas supply piping system by closing its individual

manual shutoff valve during any pressure testing of the gas supply piping system at test pressures

equal to or less than 1/2 psi (3.5 kPa).

3. Always purge the gas line of any debris and/or water before connecting to the gas inlet.

Size the gas pipe appropriately to supply the necessary volume of gas required for

the micro boiler using ANSI Z223.1/NFPA 54 in the USA of B149.1 in Canada or

local codes. Otherwise, ow capabilities and output temperatures will be limited.

CAUTION

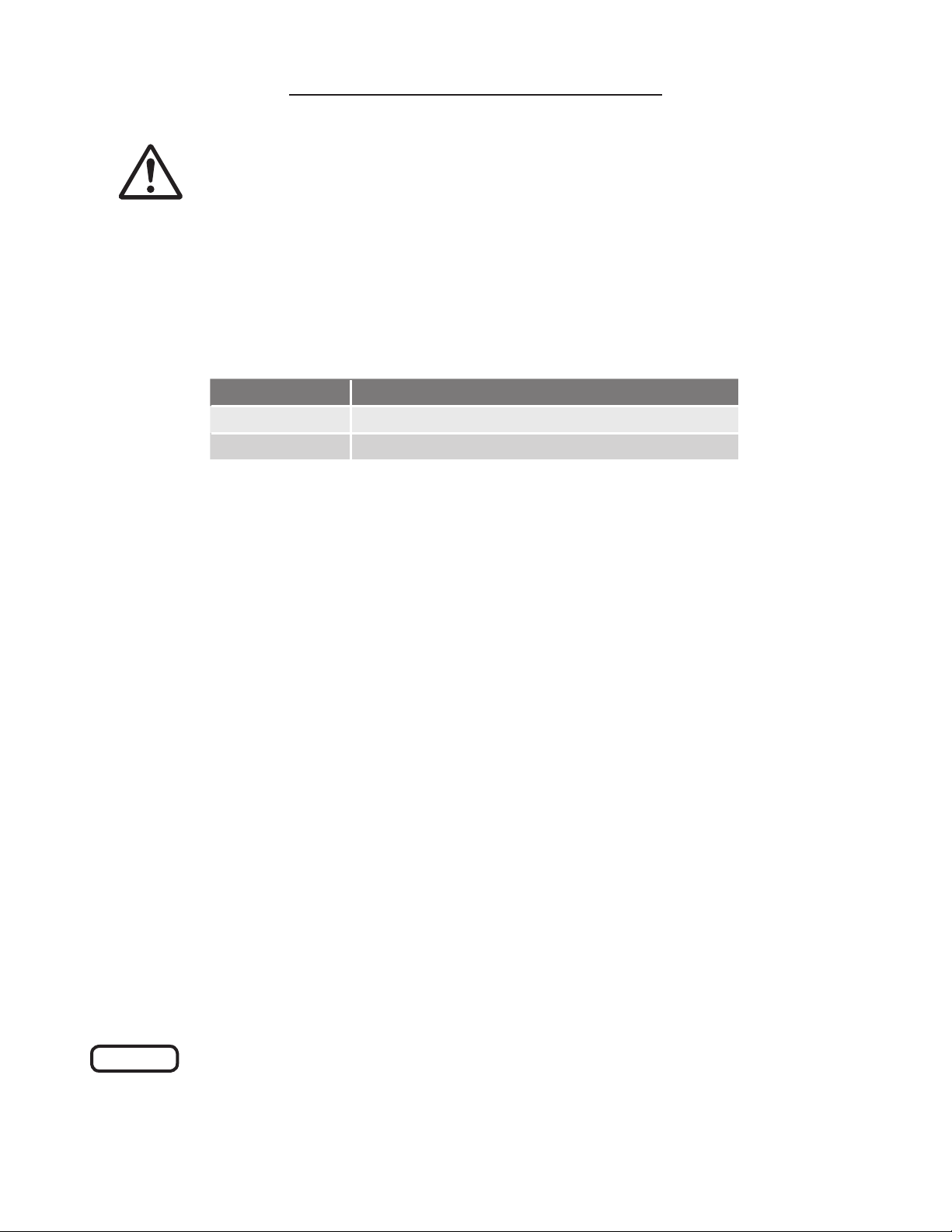

Gas type Inlet gas pressure

Natural Gas

Propane

Min. 5.0” W.C. (1.24 kPa) – Max. 10.5” W.C. (2.61 kPa)

Min. 8.0” W.C. (1.99 kPa) – Max. 14.0” W.C. (3.48 kPa)

NOTICE

Loading ...

Loading ...

Loading ...