Loading ...

Loading ...

Loading ...

• DoobtainnewwarningandinstructionlabelsfromSearsfor

placementontheblanketdirectlyovertheexistinglabels.

• Doinspecttheinsulationblanketfrequentlytomakecertain

itdoesnotsag,therebyobstructingcombustionairflow.

Combustion Air and Ventilation for

Appliances Located in Unconfined Spaces

UNCONFINED SPACE is space whose volume is not less than

50 cubic feet per 1,000 Btu per hour (4.8 m3 per kW) of the

aggregate input rating of all appliances installed in that space.

Rooms communicating directly with the space in which the

appliances are installed, through openings not furnished with

doors, are considered a part of the unconfined space.

In unconfined spaces in buildings, infiltration may be adequate

to provide air for combustion, ventilation and dilution of flue

gases. However, in buildings of tight construction (for example,

weather stripping, heavily insulated, caulked, vapor barrier,

etc.), additional air may need to be provided using the methods

described in Combustion Air and Ventilation for Appliances

Located in Confined Spaces.

Combustion Air and Ventilation for

Appliances Located in Confined Spaces

CONFINED SPACE is a space whose volume is less than

50 cubic feet per 1,000 Btu per hour (4.8 m3 per kW) of the

aggregate input rating of all appliances installed in that space.

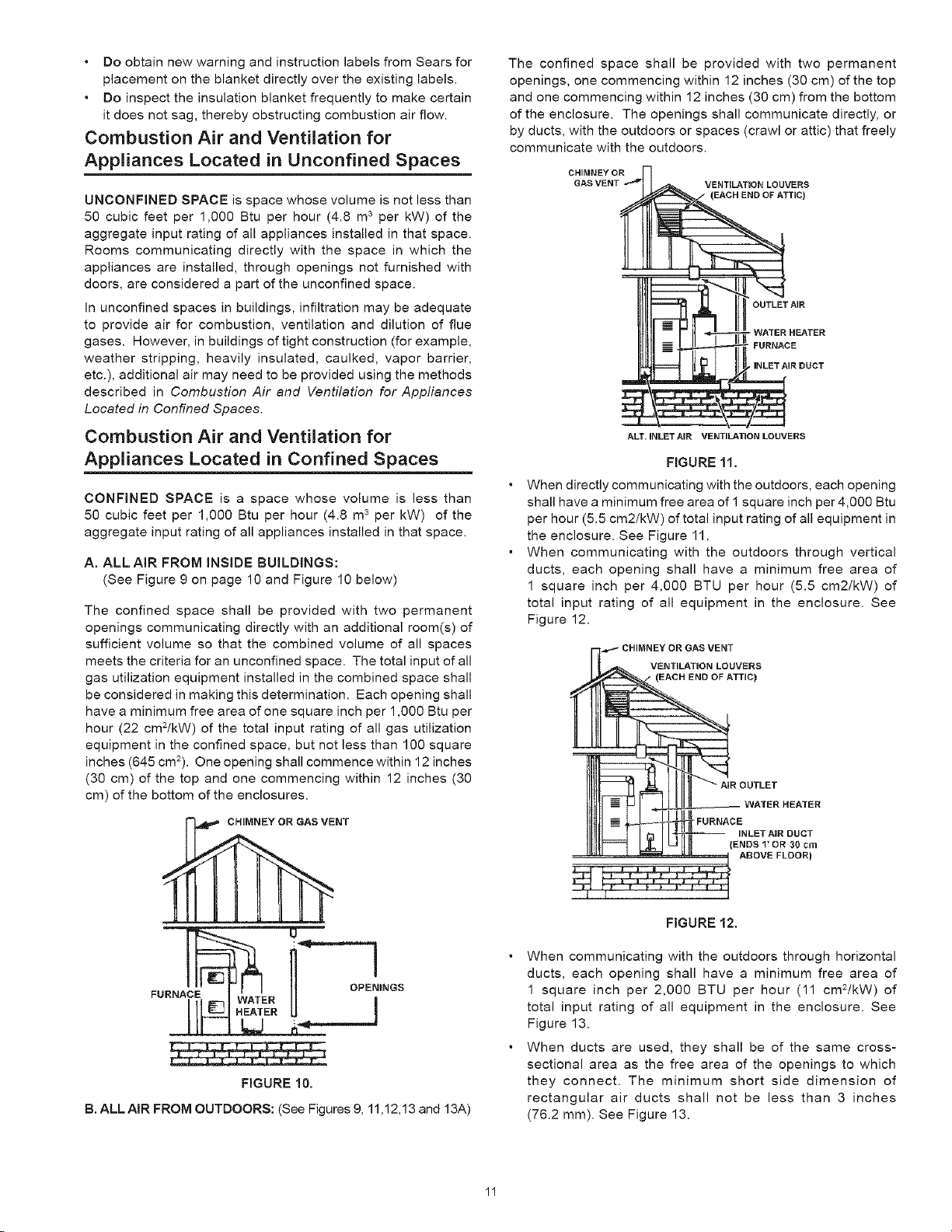

A. ALL AIR FROM INSIDE BUILDINGS:

(See Figure 9 on page 10 and Figure 10 below)

The confined space shall be provided with two permanent

openings communicating directly with an additional room(s) of

sufficient volume so that the combined volume of all spaces

meets the criteria for an unconfined space. The total input of all

gas utilization equipment installed in the combined space shall

be considered in making this determination. Each opening shall

have a minimum free area of one square inch per 1,O00 Btu per

hour (22 cm2/kW) of the total input rating of all gas utilization

equipment in the confined space, but not less than 100 square

inches (645 cm2). One opening shall commence within 12 inches

(30 cm) of the top and one commencing within 12 inches (30

cm) of the bottom of the enclosures.

NT

___OP ENINGS

FIGURE 10,

B. ALL AIR FROM OUTDOORS: (See Figures 9, 11,12,13 and 13A)

The confined space shall be provided with two permanent

openings, one commencing within 12 inches (30 cm) of the top

and one commencing within 12 inches (30 cm) from the bottom

of the enclosure. The openings shall communicate directly, or

by ducts, with the outdoors or spaces (crawl or attic) that freely

communicate with the outdoors.

CHIMNEY OR

GAS VENT VENTILATION LOUVERS

OUTLET MR

'WATERHEATER

FURNACE

INLETAIR DUCT

ALT. INLET AiR VENTILATION LOUVERS

FIGURE II.

When directly communicating with the outdoors, each opening

shall have a minimum free area of 1 square inch per 4,0go Btu

per hour (5.5 cm2/kW) of total input rating of all equipment in

the enclosure. See Figure 11.

When communicating with the outdoors through vertical

ducts, each opening shall have a minimum free area of

1 square inch per 4,000 BTU per hour (5.5 cm2/kW) of

total input rating of all equipment in the enclosure. See

Figure 12.

CHIMNEY OR GAS VENT

VENTiLATiON LOUVERS

_.,_'(EAOH END OF ATT'C)

AIR OUTLET

_ WATER HEATER

INLET AIR DUCT

IIl ll LfJL ilq--- 'Nos,'cR,oo..

ABOVE FLOOR)

FIGURE 12.

When communicating with the outdoors through horizontal

ducts, each opening shall have a minimum free area of

1 square inch per 2,000 BTU per hour (11 cm2/kW) of

total input rating of all equipment in the enclosure. See

Figure 13.

When ducts are used, they shall be of the same cross-

sectional area as the free area of the openings to which

they connect. The minimum short side dimension of

rectangular air ducts shall not be less than 3 inches

(76.2 ram). See Figure 13.

11

Loading ...

Loading ...

Loading ...