Documents: Go to download!

User Manual

- Owner's manual - (English, Spanish)

- Specification - (English)

- INSTALLATION

- OPERATION

- MAINTENANCE

- Troubleshooting

Table of contents

User manual Dryer for LG Electronics DLE7100W

INSTALLATION

Installation Location Requirements

The installation requires:

- A location that allows for proper exhaust installation. A gas dryer must be exhausted to the outdoors. See Venting the Dryer.

- A grounded electrical outlet located within 2 ft. (61 cm) of either side of the dryer. See Connecting Electric Dryers .

- A sturdy floor to support the total dryer weight of 200 lb (90.7 kg). The combined weight of a companion appliance should also be considered.

- No other fuel-burning appliance can be installed in the same closet as a dryer.

Do not operate the dryer at temperatures below 45 °F (7 °C). At lower temperatures, the dryer might not shut off at the end of an automatic cycle. This can result in longer drying times. The dryer must not be installed or stored in an area where it will be exposed to water and/or weather. Check code requirements. Some codes limit, or do not permit, installation of the dryer in garages, closets, mobile homes or sleeping quarters. Contact your local building inspector.

NOTE

- The floor must be level, with a maximum slope of 1 inch (2.5 cm) under the entire dryer. Clothes may not tumble properly, and automatic sensor cycles may not operate correctly if dryer is not level.

- For a garage installation, you will need to place the dryer at least 18 inches (46 cm) above the floor. The standard pedestal is 15 inches (38.1 cm). You will need 18 inches (46 cm) from the garage floor to the bottom of the dryer.

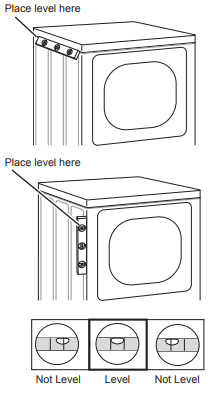

Leveling the Dryer

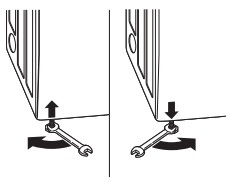

1. Position the dryer in the final location. Check levelness of dryer from side to side. Repeat from front to back.

2. Use an adjustable wrench to turn the leveling feet. Unscrew the legs to raise the dryer or screw in the legs to lower it. Raise or lower with the leveling feet until the dryer is level from side to side and front to back. Make sure that all four leveling feet are in firm contact with the floor.

If you are installing the dryer on the optional pedestal, you must use the leveling feet on the pedestal to level the dryer. The dryer leveling feet should be fully retracted.

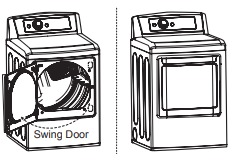

Reversing the Door

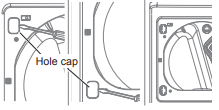

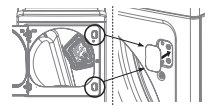

1 Open the door and remove the two plastic hole caps on the catch side by gently prying up with a flat blade screwdriver. Save these for step 6.

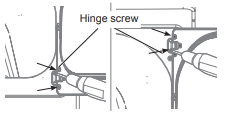

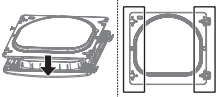

2 While supporting the door, remove the 4 screws, two from each hinge. Set the door aside face down on a protected surface to prevent damage to the door or the work surface.

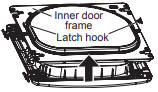

3 With the door on a protected surface, remove all screws on each side of the door and lift off the inner door frame using a flat blade screwdriver. Remove the latch hook and blank and move them to the opposite side.

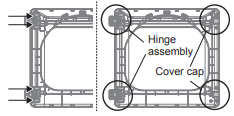

4 Remove the 4 screws securing the hinges to the door frame. Remove the two plastic cover caps. Reinstall the hinges and cover caps on the opposite sides from which they were removed.

5 With the hinges and cover caps in the new locations, remount the inner door frame onto the outer door frame with the screws removed in step 3 above.

6 Reinstall the door with the screws from steps 1,2.

7 Test the swing of the door to make sure the hinges and latch are properly aligned and that the door closes and latches correctly

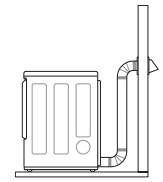

Routing And Connecting Ductwork

NOTE

Follow the guidelines below to maximize drying performance and reduce lint buildup and condensation in the ductwork. Ductwork and fittings are NOT included and must be purchased separately.

- Use 4-inch (10.2 cm) diameter rigid, semi-rigid or flexible metal ductwork.

- The exhaust duct run should be as short as possible.

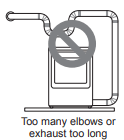

- Use as few elbow joints as possible.

- The male end of each section of exhaust duct must point away from the dryer.

- Use duct tape on all duct joints.

- Insulate ductwork that runs through unheated areas in order to reduce condensation and lint buildup on duct surfaces.

- Incorrect or inadequate exhaust systems are not covered by the dryer warranty. Dryer failures or service required because of such exhaust systems will not be covered by the dryer warranty.

Correct Venting

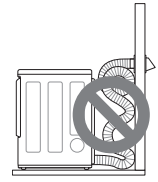

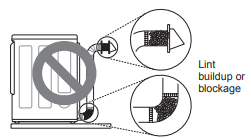

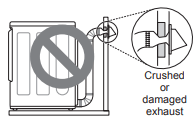

Incorrect Venting

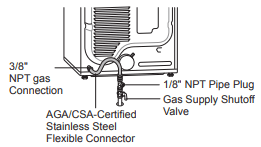

Connecting the Gas Supply

- Make sure that the gas supply to the laundry room is turned OFF and the dryer is unplugged. Confirm that the type of gas available in your laundry room is appropriate for the dryer.

- Remove the shipping cap from the gas fitting at the back of the dryer. Be careful not to damage the threads of the gas connector when removing the shipping cap.

- Connect the dryer to your laundry room’s gas supply using a new flexible stainless steel connector with a 3/8-inch NPT fitting.

- Securely tighten all connections between the dryer and your laundry room’s gas supply.

- Turn on your laundry room’s gas supply.

- Check all pipe connections (both internal and external) for gas leaks with a noncorrosive leakdetection fluid.

- Proceed to Venting the Dryer.

Installation Test (Duct Check)

Once you have completed the installation of the dryer, use this test to make sure the condition of the exhaust system is adequate for proper operation of the dryer. This test should be performed to alert you to any serious problems in the exhaust system of your home.

- This dryer features Flow Sense™, an innovative sensing system that automatically detects blockages and restrictions in dryer ductwork. Keeping ductwork clean of lint buildup and free of restrictions allows clothes to dry faster and reduces energy use.

NOTE

- The dryer should be cool before starting this test. If the dryer was warmed up during installation, run the AIR DRY cycle for a few minutes to reduce the interior temperature.

To activate the installation test:

1 Remove the drying rack and literature, and then close the door. Do not load anything in the drum for this test, as in may affect the accuracy of the results.

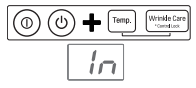

2 Press and hold the POWER, Temp., and Wrinkle Care buttons until  and a usage count alternate in the display. (The usage count indicates the number of cycles run with no load during the last 5 cycles.)

and a usage count alternate in the display. (The usage count indicates the number of cycles run with no load during the last 5 cycles.)

3 Press the START/PAUSE button. The dryer will start the test, which will last about 2 minutes. The heat will be turned on and the temperatures in the drum will be measured and displayed. A chime sounds when the test portion of the cycle is complete.

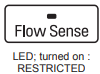

4 Check the display for results. During the test cycle, monitor the Flow Sense™ display on the control panel. If the Flow Sense™ LED is not turned on, when the cycle ends, the exhaust system is adequate. If the exhaust system is severely restricted, the Flow Sense™ LED will be turned on. Other problems may also be shown with error codes. See the chart below for error code details and solutions.

The Flow Sense™ LED indicates that the exhaust system is severely restricted. Have the system checked immediately, as performance will be poor.

5 End of cycle. At the end of the test cycle,  will display. The test cycle will end and the dryer will shut off automatically after a short delay.

will display. The test cycle will end and the dryer will shut off automatically after a short delay.

Check the error code before you call for service

tE1 or tE2

- Temperature sensor failure.

Turn off the dryer and call for service.

HS

- Humidity sensor failure.

Turn off the dryer and call for service.

PS or PF or nP

- Electric dryer power cord is not connected correctly, or house power supply is incorrect.

Check the power supply or the connection of the power cord to the terminal block. Refer to the Connecting Electric Dryers section of this manual for complete instructions.

- House fuse is blown, circuit breaker has tripped, or power outage has occurred.

Reset circuit breaker or replace fuse. Do not increase the fuse capacity. If the problem is a circuit overload, have it corrected by a qualified electrician.

gAS

- Gas supply or service turned off. (Gas Model only.)

Confirm that house gas shutoff and the dryer gas shutoff are both fully open.

Check the duct condition

- If the Flow SenseTM LED is turned on, check the ENGLISH exhaust system for restrictions and damage. Repair or replace the exhaust system as needed.

NOTE

- When the dryer is first installed, this test should be performed to alert you to any existing problems with the exhaust duct in your home. However, since the test performed during normal operation provides more accurate information on the condition of the exhaust duct than does the installation test, the number of bars displayed during the two tests may not be the same.

- Do not interrupt the test cycle, as this could result in inaccurate results.

- Even if no bars are displayed during the test cycle, some restrictions may still be present in the exhaust system. Refer to the Venting the Dryer section of this manual for complete exhaust system and venting requirements.

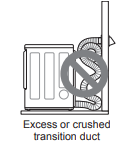

Restricted or Blocked Airflow

Avoid long runs or runs with multiple elbows or bends.

Check for blockages and lint buildup.

Make sure the ductwork is not crushed or restricted.

OPERATION

Using the Dryer

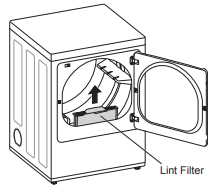

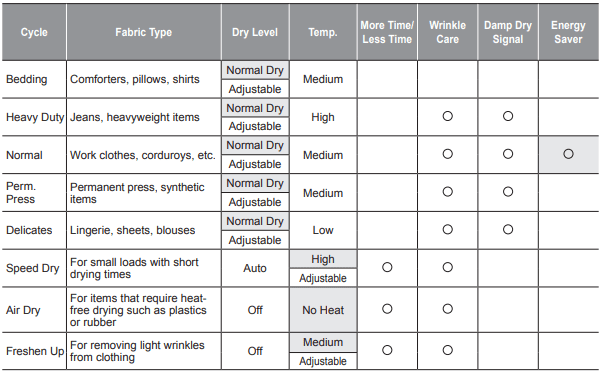

1 Clean the Lint Filter If the lint filter has not already been cleaned, lift out the filter and remove the lint from the last load. This will help ensure the fastest and most efficient drying performance. Make sure to reinstall the filter, pressing down until it clicks firmly into place. The dryer will not operate without the lint filter in place.

2 Load the Dryer Load the dryer with the wet laundry from the washer. If the load is extra large, you may need to divide it into smaller loads for proper performance and fabric care.

3 Turn on The Dryer Press the POWER button to turn ON the dryer. The cycle LEDs will illuminate and a chime will sound.

4 Select a Cycle Turn the cycle selector knob in either direction until the LED for the desired cycle is on. The preset temperature, dry level, and option settings for that cycle will be shown. Default settings for the selected cycle can now be changed if desired. Refer to the Cycle Setting and Options page for details.

5 Begin the Cycle Press the START/PAUSE button to begin the cycle. The cycle can be paused at any time either by opening the door or by pressing the START/PAUSE button. If the cycle is not restarted within 60 minutes of being paused, the dryer will shut off and the settings will be lost. Lint Filter.

6 End of Cycle When the cycle is finished, the chime will sound. Immediately remove your clothing from the dryer to reduce wrinkling. If Wrinkle Care is selected, the dryer will tumble briefly every few minutes to help prevent wrinkles from setting in the clothes.

Check the Lint Filter Before Every Load

Always make sure the lint filter is clean before starting a new load; a clogged lint filter will increase drying time. To clean, pull the lint filter straight up and roll any lint off the filter with your fingers. Do not rinse or wash the filter to remove lint. Push the lint filter firmly back into place. See Regular Cleaning for more information.

Always ensure the lint filter is properly installed before running the dryer. Running the dryer with a loose or missing lint filter will damage the dryer and articles in the dryer.

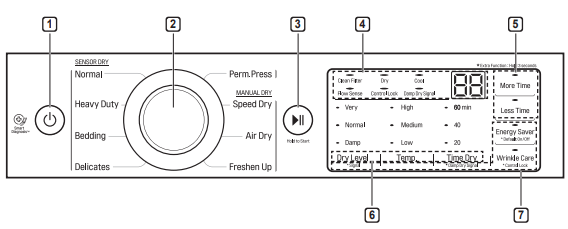

Control Panel

1 POWER Button

Press to turn the dryer ON. Press again to turn the dryer OFF.

2 Cycle Selector Knob

Turn this knob to select the desired cycle. Once the desired cycle has been selected, the standard presets are shown in the display. On Manual Dry cycles, these settings can be adjusted using the cycle modifier buttons any time before starting the cycle.

3 START/PAUSE Button

Press this button to start the selected cycle. If the dryer is running, use this button to pause the cycle without losing the current settings.

4 Time and Status Display

The display shows the settings, estimated time remaining, options, and status messages for the dryer.

5 More Time/Less Time Buttons

Use these buttons with the Time Dry and other Manual Dry cycles to adjust the drying time. Press the More Time button to increase the selected manual cycle time by 1 minute; press the Less Time button to decrease the cycle time by 1 minute.

6 Cycle Modifier Buttons

Use these buttons to select the desired cycle settings for the selected cycle. The current settings are shown in the display. Press the button for that modifier to select other settings.

7 Cycle Option Buttons

The option buttons allow you to select additional cycle options. Certain buttons also allow you to activate special functions by pressing and holding the button for 3 seconds.

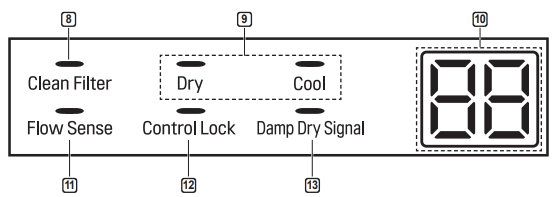

8 Clean Filter Reminder

The display will show Clean Filter when the dryer is turned on as a reminder to check the filter. It turns off when the START/PAUSE button is pressed.

9 Cycle Completion Indicator with Check Filter Reminder

This portion of the display shows which stage of the drying cycle is currently underway (Dry, Cool).

10 Estimated Time Remaining

This display shows the estimated time remaining for SENSOR DRY cycles or the actual time remaining for Time Dry or MANUAL DRY cycles.

11 Flow Sense™ Duct Blockage Sensing System Indicator

The Flow Sense™ duct blockage sensing system detects and alerts you to blockages in the ductwork that reduce exhaust flow from the dryer. Maintaining a clean exhaust system improves operating efficiency and helps minimize service calls, saving you money.

12 Control Lock Indicator

When Control Lock is set, the Control Lock indicator appears and all buttons are disabled except the POWER button. This prevents children from changing settings while the dryer is operating.

13 Damp Dry Signal Indicator

The dryer will signal when the load is approximately 80% dry. This allows you to remove faster- drying lightweight items or items that you would like to iron or hang while still slightly damp.

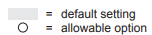

Cycle Guide

Cycle Settings and Options

Cycle Modifier Buttons

SENSOR DRY cycles have preset settings that are selected automatically. MANUAL DRY cycles have default settings, but you may also customize the settings using the cycle modifier buttons. Press the button for that option to view and select other settings.

Dry Level

Selects the level of dryness for the cycle. Press the Dry Level button repeatedly to scroll through available settings.

- This option is only available with SENSOR DRY cycles.

- The dryer will automatically adjust the cycle time. Selecting Very Dry will increase the cycle time, while Damp Dry will decrease the cycle time.

- Use a Damp Dry setting for items that you wish to iron.

Temp.

- Adjusts the temperature setting. This allows precise care of your fabrics and garments. Press the Temp. button repeatedly to scroll through available settings.

Time Dry

- Allows you to manually select the drying time, from 20 to 60 minutes, in 10-minute increments. Use this for small loads or to remove wrinkles.

More Time/Less Time

- Use the More Time/Less Time buttons to add or reduce the drying time of a MANUAL DRY cycle in 1-minute increments.

Cycle Option Buttons

The dryer features several additional cycle options to customize cycles to meet individual needs. Certain option buttons also feature a special function that can be activated by pressing and holding that option button for 3 seconds. (See Special Functions on the following page for details.)

Adding Cycle Options to a Cycle:

- Turn on the dryer and turn the cycle selector knob to select the desired cycle.

- Use the cycle modifier buttons to adjust the settings for that cycle.

- Press the cycle option button(s) for the option you would like to add. A confirmation message is shown in the display.

- Press the START/PAUSE button to start the cycle. The dryer starts automatically

Special Functions

Some cycle option buttons also activate secondary functions. These special functions are marked with an asterisk (*). Press and hold the option button marked with the special function to activate it.

* Control Lock

- Use this option to prevent unwanted use of the dryer or to keep cycle settings from being changed while the dryer is operating.

- Press and hold the button marked *Control Lock for 3 seconds to activate or deactivate the Control Lock function. The Control Lock icon will be shown in the display, and all controls will be disabled except the POWER button.

NOTE Once set, Control Lock remains active until it is manually deactivated. Control Lock must be turned off to run another cycle. To deactivate Control Lock, press and hold the *Control Lock button for 3 seconds.

* Damp Dry Signal

- With this option, the dryer will signal when the load is approximately 80% dry. This allows you to remove faster- drying lightweight items or items that you would like to iron or hang while still slightly damp.

* Default On/Off

- This option allows the Energy Saver settings to be changed. To run a Normal cycle without the Energy Saver option, press and hold the Energy Saver button for three seconds. ON or OFF appears in the display.

* SIGNAL

Press and hold the Dry Level button for 3 seconds to adjust the volume of the signal. Press and hold the button repeatedly to adjust the volume of the melody. When no signal is heard, the signal is off. The volume settings are ON – OFF. The signal volume can be adjusted at any time as long as the dryer is turned ON.

MAINTENANCE

Cleaning the Exterior

Proper care of your dryer can extend its life. The outside of the machine can be cleaned with warm water and a mild, nonabrasive household detergent. Immediately wipe off any spills with a soft, damp cloth.

NOTE

- Do not use methylated spirits, solvents, or similar products.

- Never use steel wool or abrasive cleansers; they can damage the surface.

Cleaning the Interior

- Wipe around the door opening and seal with a soft, damp cloth to prevent lint and dust buildup that could damage the door seal.

- Clean the window with a soft cloth dampened with warm water and a mild, nonabrasive household detergent, then wipe dry.

- The stainless steel drum can be cleaned with a conventional stainless steel cleaner, used according to the manufacturer’s specifications. Never use steel wool or abrasive cleansers; they may scratch or damage the surface.

Cleaning Around and Under the Dryer

- Vacuum lint and dust from around the dryer and underneath it regularly. Vent ductwork should be checked for lint buildup and cleaned at least once per year. If any noticeable reduction in airflow or drying performance occurs, immediately check ductwork for obstructions and blockages.

Maintaining Ductwork

Vent ductwork should be checked for lint buildup once per month and cleaned at least once per year. If any noticeable reduction in airflow or drying performance occurs, immediately check ductwork for obstructions and blockages. Contact a qualified technician or service provider.

Cleaning the Lint Filter

Always clean the lint from the filter after every cycle.

To clean, open the dryer door and pull the lint filter straight up. Then:

1 For everyday cleaning, roll any lint off the filter with your fingers, or

2 Vacuum the lint filter.

3 If the lint filter has become very dirty or clogged with fabric softener, wash the lint filter in warm, soapy water and allow it to dry thoroughly before reinstalling.

NOTE NEVER operate the dryer without the lint filter in place. NEVER operate the dryer with a wet lint filter.

Troubleshooting

FAQs: Frequently Asked Questions

Q: When I press a button, why does my dryer beep and then nothing happens?

A: The Control Lock feature is turned on. To turn off Control Lock, turn the dryer on, then press and hold the button that has *Control Lock on or under it for 3 seconds.

Q: Why does my dryer take so long to dry clothes?

A: Proper airflow is critical to the efficient operation of clothes dryers. A lint filter which is full of lint or clogged with fabric softener sheet residue can reduce the airflow to the point that the time required to dry clothing will be greatly increased. Another factor affecting dry time is your home exhaust system. An exhaust system which is dirty and clogged with lint, or is excessively long, needs to be professionally cleaned or repaired.

Q: Why does my dryer start by itself every few minutes?

A: This is how the Wrinkle Care feature works. The dryer runs briefly every few minutes for up to 3 hours after the cycle finishes. This feature is designed to help prevent wrinkles from setting in when the dryer is not unloaded immediately after the cycle is finished.

Before Calling for Service

This dryer is equipped with an automatic error-monitoring system to detect and diagnose problems at an early stage. If the dryer does not function properly or does not function at all, check the following before you call for service.

Operation

The Flow SenseTM indicator remains active after clearing the restriction in the venting.

- After clearing the restriction, the Flow SenseTM system requires multiple, consecutive cycles to determine that the performance value has improved before the Flow SenseTM indicator is reset.

If the Flow SenseTM indicator remains active for more than five cycles after the restriction has been cleared, call for service.

Dryer will not turn on

- Power cord is not properly plugged in.

Make sure that the plug is securely plugged into a grounded outlet matching the dryer’s rating plate.

- House fuse is blown, circuit breaker has tripped, or power outage has occurred.

Reset circuit breaker or replace fuse. Do not increase fuse capacity. If the problem is a circuit overload, have it corrected by a qualified electrician.

Dryer does not heat

- House fuse is blown, circuit breaker has tripped, or power outage has occurred.

Reset circuit breaker or replace fuse. Do not increase fuse capacity. If the problem is a circuit overload, have it corrected by a qualified electrician.

NOTE Due to the design of electric dryers, it is possible for a circuit problem to allow an electric dryer to run without heat.

- Gas supply or service is turned off (gas models only).

Confirm that the house gas shutoff and the dryer gas shutoff valves are both fully open. Even if gas is not supplied to the dryer, it will run and display error code. Verify that other gas appliances in the home are working normally

- Energy Saver option selected (on some models)

If using the Cotton/Normal cycle, deselect the energy saver option. The Energy Saver option is selected by default. This option reduces energy use by adding an air dry section to the beginning of the cycle. It is normal to feel no heat at the beginning of the cycle while in Energy Saver mode.

Display show error code nP

- Electric dryer power cord is not connected correctly, or house power supply is incorrect.

Check the power supply or the connection of the power cord to the terminal block.

Display show error code gAS

- Gas supply or service turned off (gas models only).

Confirm that house gas shutoff and the dryer gas shutoff are both fully open.

Clothes take too long to dry

- Exhaust ducts are blocked, dirty, or duct run is too long.

Confirm that the exhaust duct is properly configured and free of debris, lint, and obstructions. Make sure that outside wall dampers can open properly and are not blocked, jammed, or damaged.

- Load is not properly sorted.

Separate heavy items from lightweight items. Larger and heavier items take longer to dry. Light items in a load with heavy items can fool the sensor because the light items dry faster.

Clothes take too long to dry

- Large load of heavy fabrics

Heavy fabrics take longer to dry because they tend to retain more moisture. To help reduce and maintain more consistent drying times for large and heavy fabrics, separate these items into smaller loads of a consistent size.

- Dryer controls are not set properly.

Use the appropriate control settings for the type of load you are drying. Some loads may require an adjustment of the dry level setting for proper drying.

- Lint filter needs to be cleaned.

Remove the lint from the filter before every load. With the lint removed, hold the filter up to a light to see if it is dirty or clogged. With some loads that produce high amounts of lint, such as new bath towels, it may be necessary to pause the cycle and clean the filter during the cycle.

- House fuse is blown, circuit breaker has tripped, or power outage has occurred.

Reset circuit breaker or replace fuse. Do not increase fuse capacity. If the problem is a circuit overload, have it corrected by a qualified electrician.

NOTE Due to the design of electric dryers, it is possible for a circuit problem to allow an electric dryer to run without heat.

- Dryer is overloaded.

Divide extra large loads into smaller loads for better drying performance and efficiency.

- Dryer is underloaded.

If you are drying a very small load, add a few extra items to ensure proper tumbling action. If the load is very small and you are using SENSOR DRY cycles, the electronic control cannot properly sense the dryness of the load and may shut off too soon. Use TIME DRY or add some extra wet clothes to the load.

Clothes take too long to dry

- Clothes take too long to dry

If using the Cotton/Normal cycle, deselect the Energy Saver option. This option reduces energy use by adding an air dry section to the beginning of the cycle.

Drying time is not consistent

- Heat settings, load size, or dampness of clothing is not consistent.

The drying time for a load will vary depending on the type of heat used (electric, natural gas, or LP gas), the size of the load, the type of fabrics, the wetness of the clothes, and the condition of the exhaust duct and lint filter. Even an unbalanced load in the washer can cause poor spinning, resulting in wetter clothes which will take longer to dry

Performance

Greasy or dirty spots on clothes

- Fabric softener used incorrectly.

Confirm and follow the instructions provided with your fabric softener.

- Clean and dirty clothes are being dried together.

Use your dryer to dry only clean items. Soil from dirty clothes can transfer to the clean clothes in the same or later loads.

- Clothes were not properly cleaned or rinsed before being placed in the dryer.

Stains on dried clothes could be stains that were not removed during the washing process. Make sure that clothes are being completely cleaned or rinsed according to the instructions for your washer and detergent. Some difficult soils may require pre-treating prior to washing.

Clothes are wrinkled

- Clothes dried too long (over dried).

Over drying a load of laundry can lead to wrinkled clothes. Try a shorter drying time or LESS DRY setting and remove items while they still retain a slight amount of moisture.

- Clothes dried too long (over dried).

Use the WRINKLE CARE option. This feature will tumble the clothes briefly every few minutes for up to 3 hours to help prevent wrinkling.

Clothes are shrinking

- Garment care instructions are not being followed.

To avoid shrinking your clothes, always consult and follow fabric care instructions. Some fabrics will naturally shrink when washed. Other fabrics can be washed but will shrink when dried in a dryer. Use a low or no heat setting.

Lint on clothes

- Lint filter not cleaned properly

Remove the lint from the filter before every load. With the lint removed, hold the filter up to a light to see if it is dirty or clogged. If it looks dirty, follow the cleaning instructions. With some loads that produce high amounts of lint, it may be necessary to clean the filter during the cycle.

- Laundry not sorted properly.

Some fabrics are lint producers (i.e., a fuzzy white cotton towel) and should be dried separately from clothes that are lint trappers (i.e., a pair of black linen pants).

Lint on clothes

- Excess static in clothes.

Use a fabric softener to reduce static electricity. Be sure to follow the manufacturer’s instructions. Overdrying a load of laundry can cause a buildup of static electricity. Adjust settings and use a shorter drying time, or use SENSOR DRY cycles.

- Dryer is overloaded.

Divide extra large loads into smaller loads for drying.

- Tissue, paper, etc., left in pockets.

Check pockets thoroughly before washing and drying clothes.

Excess static in clothes after drying

- Fabric softener is not used or used incorrectly

Use a fabric softener or the STATIC SHIELD option, if equipped, to reduce static electricity. Be sure to follow the manufacturer’s instructions.

- Clothes dried too long (overdried).

Overdrying a load of laundry can cause a buildup of static electricity. Adjust settings and use a shorter drying time, or use AUTO DRY cycles. Select a LESS DRY setting on SENSOR DRY cycles, if necessary.

- Drying synthetics, permanent press, or synthetic blends.

These fabrics are naturally more prone to static buildup. Try using fabric softener, or use LESS DRY and/or shorter TIME DRY time settings.

Clothes have damp spots after a SENSOR DRY cycle.

- Very large load or very small load. Single large item such as a blanket or comforter.

If items are too tightly packed or too sparse the sensor may have trouble reading the dryness level of the load. Use a Time Dry cycle for very small loads.

Large, bulky items such as blankets or comforters can sometimes wrap themselves into a tight ball of fabric. The outside layers will dry and register on the sensors, while the inner core remains damp. When drying a single bulky item, it may help to pause the cycle once or twice and rearrange the item to unwrap and expose any damp areas.

To dry a few remaining damp items from a very large load or a few damp spots on a large item after a sensor cycle has completed, empty the lint trap, then set a Time Dry cycle to finish drying the item(s).

Error Codes

Error code: tE1 through tE7

- Temperature sensor failure.

Turn off the dryer and call for service.

Display shows error code: PS (electric dryers only)

- Power cord is connected incorrectly.

Check the connection of the power cord to the terminal block.

*Flow SenseTM indicator shows four bars during the drying cycle or the display shows "d80" after drying

- Exhaust system is too long or has too many turns/restrictions.

Install a shorter or straighter duct run. See the Installation Instructions for details.

- Partial blockage of the ductwork due to lint buildup or other foreign object.

Ductwork should be checked/cleaned immediately. Dryer can be used in this condition, but drying times will be longer and energy consumption will increase.

* This warning light is not a dryer failure and is not covered by the dryer warranty. Contact a duct cleaning service to set up an appointment to have your exhaust system cleaned and inspected.

- The appliance has detected a restriction in the external dryer venting

If exhaust restrictions are sensed by the Flow SenseTM system, the indicator will remain on for 2 hours after the end of the cycle. Opening the door or pressing the POWER button will turn off the display

The Flow SenseTM indicator remains active after clearing the restriction in the venting.

- After clearing the restriction, the Flow SenseTM system requires multiple, consecutive cycles to determine that the performance value has improved before the Flow SenseTM indicator is reset.

If the Flow SenseTM indicator remains active for more than five cycles after the restriction has been cleared, call for service.

Clean Filter: indicator light is on during the drying cycle

- Lint filter not cleaned properly.

Remove the lint from the filter before every load. With the lint removed, hold the filter up to a light to see if it is dirty or clogged. If it looks dirty, follow the cleaning instructions. With some loads that produce high amounts of lint, it may be necessary to clean the filter during the cycle.

The display shows d90, d95

- The duct work is about 90%-95% blocked.(“d90” or “d95” error code is displayed for 2 hours only)

Do not use the dryer until the exhaust system has been cleaned and/or repaired. Using the dryer with a severely restricted exhaust is dangerous and could result in a fire or other property damage.

- House exhaust system blocked.

Check the outside dryer vent while the dryer is operating to make sure there is strong airflow.

If the exhaust system is extremely long, have it repaired or rerouted.

Keep the area around the dryer clean and free of clutter.

Check vent hood for damage or lint clogging.

Make sure the area around the vent hood is clear.

See other models: BP540 W2452T-TF LSC27914SB LSDF9969BD LG357