Loading ...

Loading ...

Loading ...

7

bottom baseplate, you should also see three white plastic

parts: a short azimuth bushing, a long azimuth bushing,

and a flat PTFE/UHMW bearing ring (Figure 4). The

bushings may have remained lodged in the center hole of

the baseplate(s) when you removed it. If that’s the case,

use a finger to push the bushing out of the hole. Set the

bottom baseplate and associated parts aside for now

while you install the vertical stop L-bracket on the top

baseplate.

2. Install the vertical stop L-bracket. It will be permanently

installed on the top baseplate (Figure 5). The vertical

stop L-bracket will be used before each observing

session to set the precise vertical orientation of the

optical tube, the procedure for which will be described

later. Once installed, the L-bracket will never have to be

removed because it does not interfere with the range of

motion of the optical tube between vertical and horizontal

positions.

To install the vertical stop L-bracket, insert the two 25mm

(~1") machine screws through the two holes in the

L-bracket’s foot. Then insert the screws into the holes in

the top baseplate, with the L-bracket oriented as shown

in Figure 5. On the underside of the top baseplate,

place a small lock washer on the end of each screw,

then thread on a small hex nut. While holding the hex nut

stationary with two fingers, tighten the screw with a small

Phillips screwdriver. Repeat for the other screw. Now the

L-bracket is secured in place.

Note: You may discard the two small flat washers for the

25mm machine screws that were included in the hardware kit;

they are not needed.

3. Thread the vertical stop bolt and knob into the

corresponding hole in the vertical stop bracket, in the

orientation show in Figure 5. Thread it though so that

1/2" or so of the bolt emerges on the other side of the

L-bracket, then thread on the jam nut. You will adjust the

position of the vertical stop bolt and tighten the jam nut

later, when initializing the IntelliScope system prior to

using it for the first time.

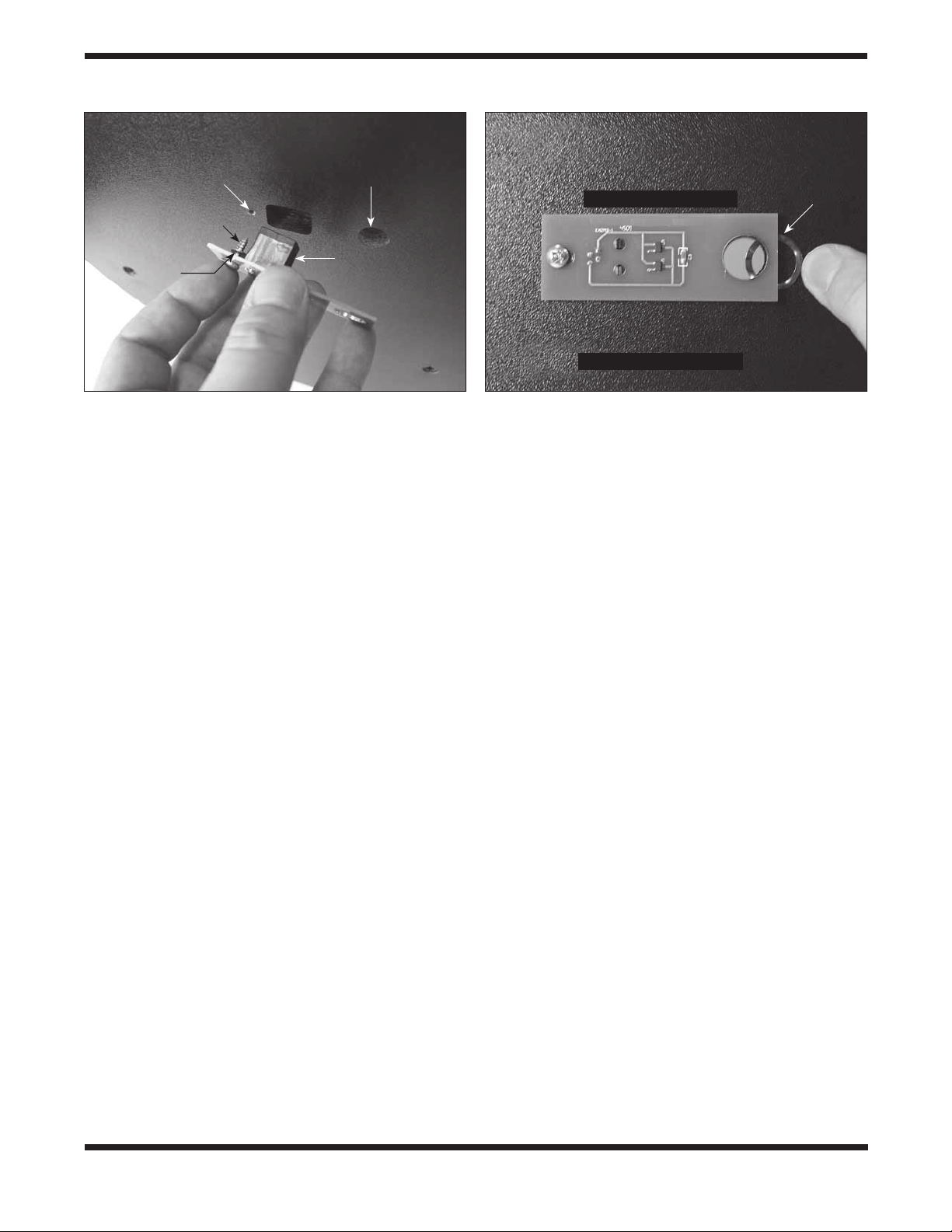

4. Attach the azimuth encoder board to the underside of the

top baseplate (Figure 6). Insert a wood screw through

the slot in the azimuth encoder board, then place a

washer over the tip of the screw. Now hold the encoder

board so that the modular jack and large hole in the

encoder board line up with their corresponding holes

in the baseplate. Insert the screw tip into the pre-drilled

starter hole and screw it in with a Phillips screwdriver

until just tight. The screw should not be fully tightened;

it should be tight, but not tight enough to prevent the

encoder board from moving in its slot.

5. Place the wave spring between the azimuth encoder

board and the bottom of the top baseplate as shown

in Figure 7. Position the wave spring so that it aligns

precisely with the central hole in the baseplate.

Now that the azimuth encoder is installed on the underside of

the top baseplate, be sure not to set the baseplate down on a

flat surface, as doing so could damage the encoder. Rather,

set the baseplate with attached vertical side panel assembly

on its side for now.

6. Place one fender washer on the azimuth axis bolt,

followed by the short nylon bushing. Then insert the bolt

through the central hole from the underside of the bottom

Figure 7. Wedge the wave spring between the azimuth

encoder board and the baseplate and align the “hole” in the

wave spring with the central hole in the baseplate.

Figure 6. Install the azimuth encoder board on the under-

side of the top baseplate. Be sure to place one washer on

the screw after inserting the screw through its hole in the

azimuth board, then thread the screw into the predrilled

starter hole.

Wave

spring

Pre-drilled

starter hole

Wood screw

Washer

Center hole

Modular jack

Altazimuth encoder board

Under side of top baseplate

Under side of top baseplate

Loading ...

Loading ...

Loading ...