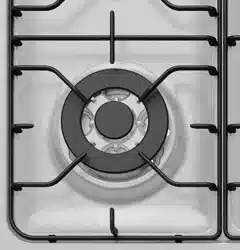

GAS COOKTOPS

User and Installation Manual

MODELS

CHG642SB/WB, CHG646SB/WB, CHG606SB,

CHG956SB/WB, SHG646SB, SHG956SB,

ZHG645SA,ZHG955SA

WHG640SB/WB, WHG640SC/WC, WHG643SA/SB,

WHG645SA/WA, WHG645SB/WB,WHG951SB,

WHG953SB,WHG955SA/WA,WHG955SB/WB

Loading ...

Loading ...

Loading ...