Loading ...

Loading ...

Loading ...

Frame/nose leaks air O-ring or Gasket is cut or cracked . . . .Replace O-ring or gasket

Bumper cracked/worn . . . . . . . . . . . . .Replace bumper

Frame/cap leaks air Damaged gasket or seal . . . . . . . . . . .Replace gasket or sea

Loose cap screws . . . . . . . . . . . . . . . .Tighten and recheck

Failure to cycle Air supply restriction . . . . . . . . . . . . . . .Check air supply equipment

Broken cylinder cap spring . . . . . . . . . .Replace cylinder cap spring

Lack of power; slow to cycle Broken cylinder cap spring . . . . . . . . . .Replace cap spring

O-rings/seals cut or cracked . . . . . . . . .Replace O-rings/seals

Exhaust blocked . . . . . . . . . . . . . . . . .Check bumper, head valve spring, muffler

Dirt/tar build up on driver . . . . . . . . . . .Disassemble nose/driver to clean

Air pressure too low . . . . . . . . . . . . . . .Check air supply equipment

-9-

TROUBLE SHOOTING

PROBLEM CAUSE CORRECTION

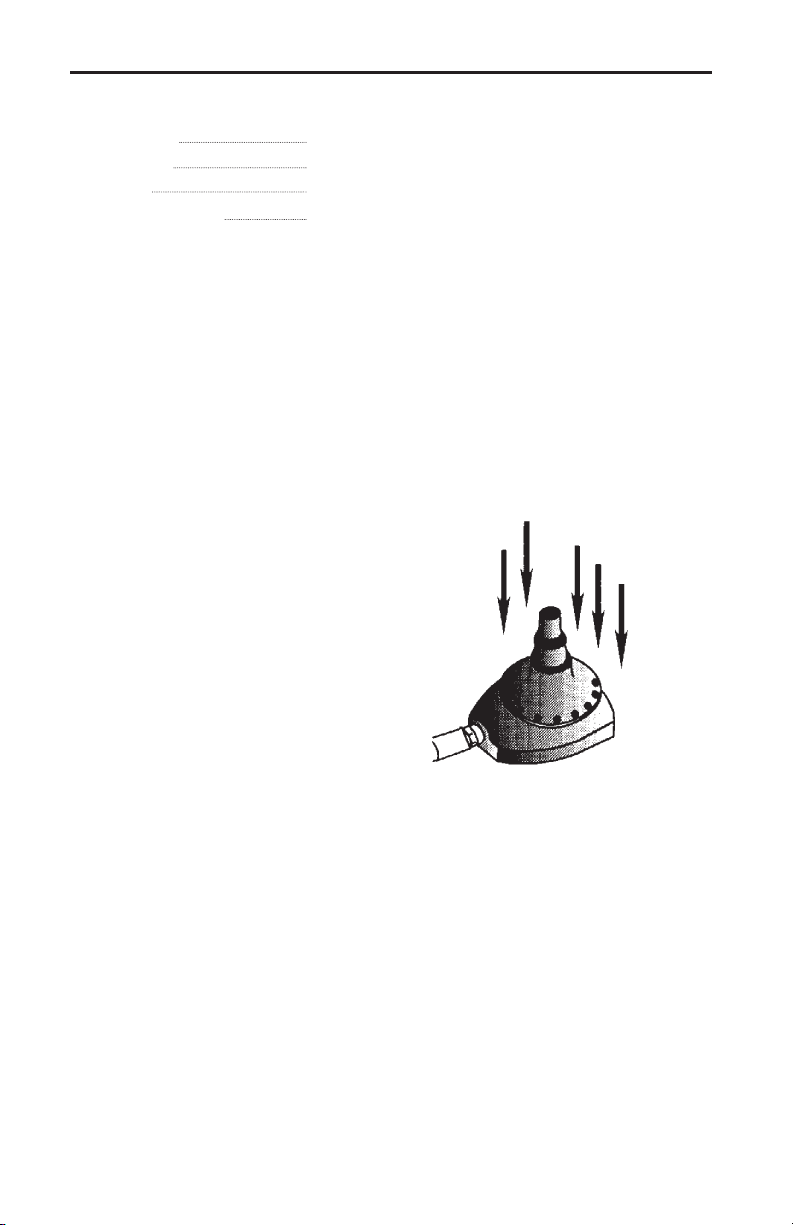

1. If the tool is dropped after the air supply is

shut off, the internal cycling mechanism may

assume mid-cycle position. When resupplied

with air, the tool will remain inoperative and

leak air. To reset the internal valve, abruptly

slap the tool cap with the palm of the hand to

jar the valve into proper position.

Loading ...

Loading ...

Loading ...