Loading ...

Loading ...

Loading ...

Advanced Technology

07-08

Cleaning-free Pipe Reuse Technology

<

PUHZ-RP71–200

>

Ability to use existing piping reduces pipe waste and replacement time

No Need to Clean at the Time of System Renewal

Chloride residue builds up in existing pipes and becomes a source of trouble. In addition, the iron particles and slime produced as a result of

compressor failure lead to problems. To counter this, various original Mitsubishi Electric technologies have been combined to enable the introduction

of “cleaning-free pipe reuse.”

This feature is available in the PUHZ-RP71-200

Cautions when using existing piping

•When removing an old air conditioning unit, please make sure to perform the pump-down process and recover the refrigerant and refrigerant oil.

•Check to ensure that the piping diameter and thickness match Mitsubishi Electric specications.

•Check to ensure that the are is compatible with R410A.

Cleaning pipe or replacing with new pipe is required

Result

R22 refrigerant R410A refrigerant

Accelerated deterioration

of refrigerant oil

Problem

High heat generated

during operation

Problem

Chloride residue

Increased chloride

residue

Iron particles and slime

Refrigerant circuit

malfunctions and

causes failure

At time of renewal

At time of

compressor failure

Countermeasure for Problem 1 Countermeasure for Problem 2

Technology 2

Friction Reduction

(moving parts in compressor)

Friction inside the compressor is reduced by using an

original Mitsubishi Electric technology called the

“Heat Caulking Fixing Method” or coating the edge of

the blade in the scroll compressor, thereby

suppressing the increase in temperature that causes

refrigerant oil deterioration.

Technology 1

Original High-quality Filtration

Our original high-quality ltration device called

the “Wide strainer” is equipped inside the

refrigerant inlet and outlet pipe. The “Wide

strainer” traps iron particles and provide

cleaning-free pipe reuse. In addition,

improvements to the metal used in the

bearings of our new scroll compressors provide

more robust units.

Existing piping can be used without cleaning

Why can’t existing piping be used?

Mitsubishi Electric’s Original Replacement Technologies

“Wide strainer”

1 2

see specication on Page 24

Advanced Energy-ecient Technologies

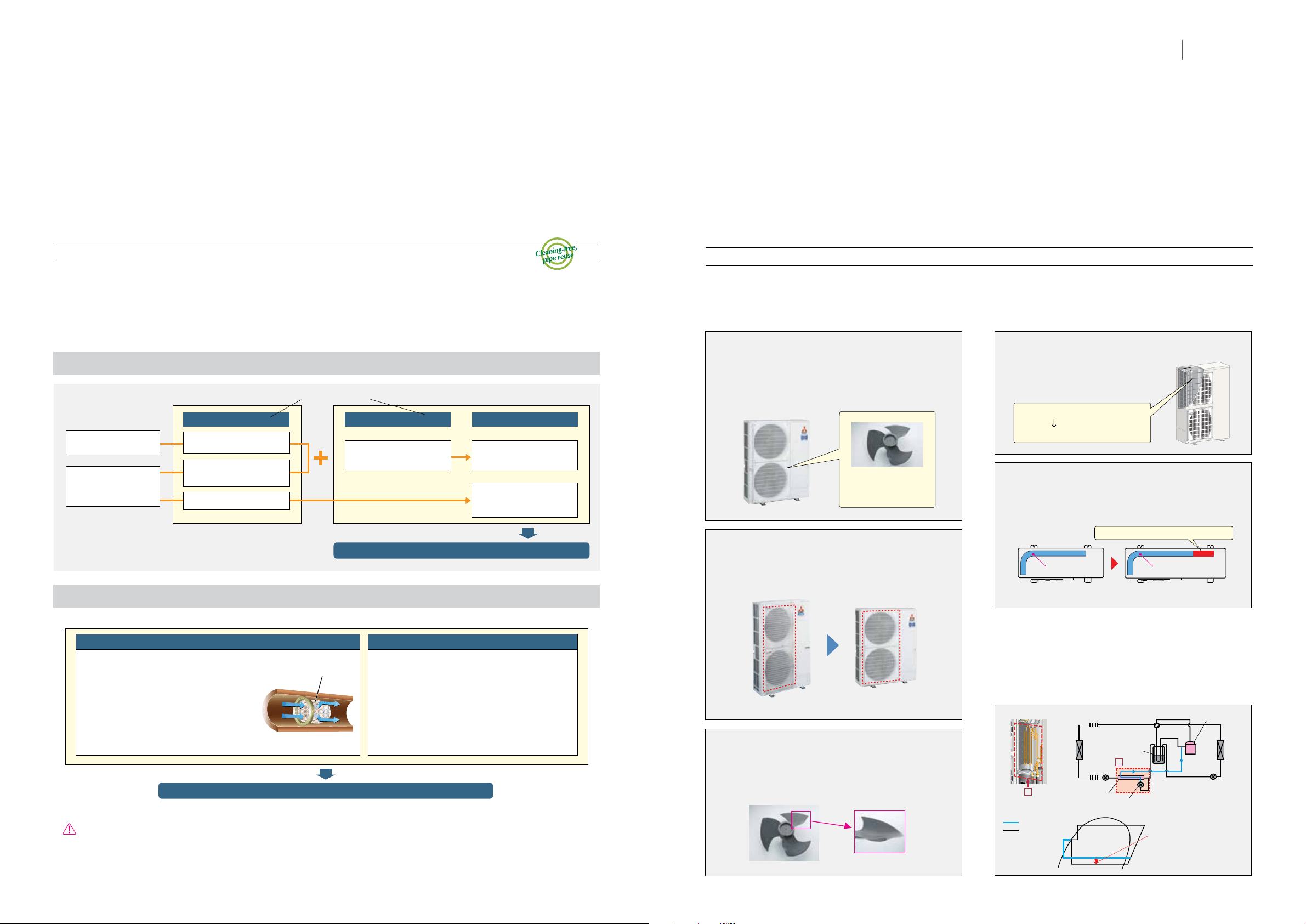

Highly ecient fan and grille for outdoor unit

The shapes of the fan and grille of the outdoor unit have been redesigned,

realising an increase in blowing capacity and more ecient heat exchange

while maintaining the same operating noise level.

Highly ecient heat exchanger

A high density and increase in surface area have improved the

heat-exchange eciency of the heat exchanger.

Fan rear edge

Outdoor unit fan opening increased <PUHZ-RP100-200>

The diameter of the opening for the fan in the outdoor unit has

been increased from 490 to 550mm. Blowing capacity has been

increased while maintaining the same fan rotation speed.

High-density heat exchanger

<PUHZ-RP100-200>

The pipe diameter has been changed

from 9.52 to 7.94mm, resulting in a

high-density heat exchanger.

Grille shape changed

<PUHZ-RP71-200>

The shape of the air outlet grille has been changed to reduce

pressure loss. This has helped to improve heat exchange

performance.

Inexed fan

<PUHZ-RP100-200>

Adoption of a fan with improved ventilation characteristics and

a newly designed rear edge that suppresses wind turbulence

raises fan operation eciency.

Heat-exchange surface area increased

<

PUHZ–RP100–200

>

Heat exchanger size extended horizontally, increasing the

surface area.

Heat exchanger

Heat exchanger

Increase in heat-exchanger surface area

Opening increased

from 490 to 550mm

in diameter

2 lines, 52 columns

2 lines, 64 columns

(

RP100 –200

)

Increasing the pressure of the

refrigerant sent to the compressor

reduces the compression load

w/ HIC circuit

w/o HIC circuit

Heat Interchanger (HIC)

LEV B

LEV C

LEV A

Heat

interchanger

(HIC)

A

A

Indoor

HEX

Outdoor

HEX

Power

receiver

Compressor

Cooling operation

<

PUHZ–RP

•

HA

> <

PUHZ–RP

•

KA

>

<

PUHZ–RP

•

HA

>

(image)

<

PUHZ–RP

•

KA

>

Heat Interchanger

(

HIC

)

Added

<PUHZ-RP140>

A HIC circuit has been added to improve energy eciency during cooling

operation. Liquid refrigerant is rerouted, transformed into a gas state and

injected back into the system to increase overall pressure of the refrigerant

being sent to the compressor, thereby reducing the load on the

compressor and raising eciency.

see specication on Page 24

Loading ...

Loading ...

Loading ...