Loading ...

Loading ...

Loading ...

Instructions for the installer

26

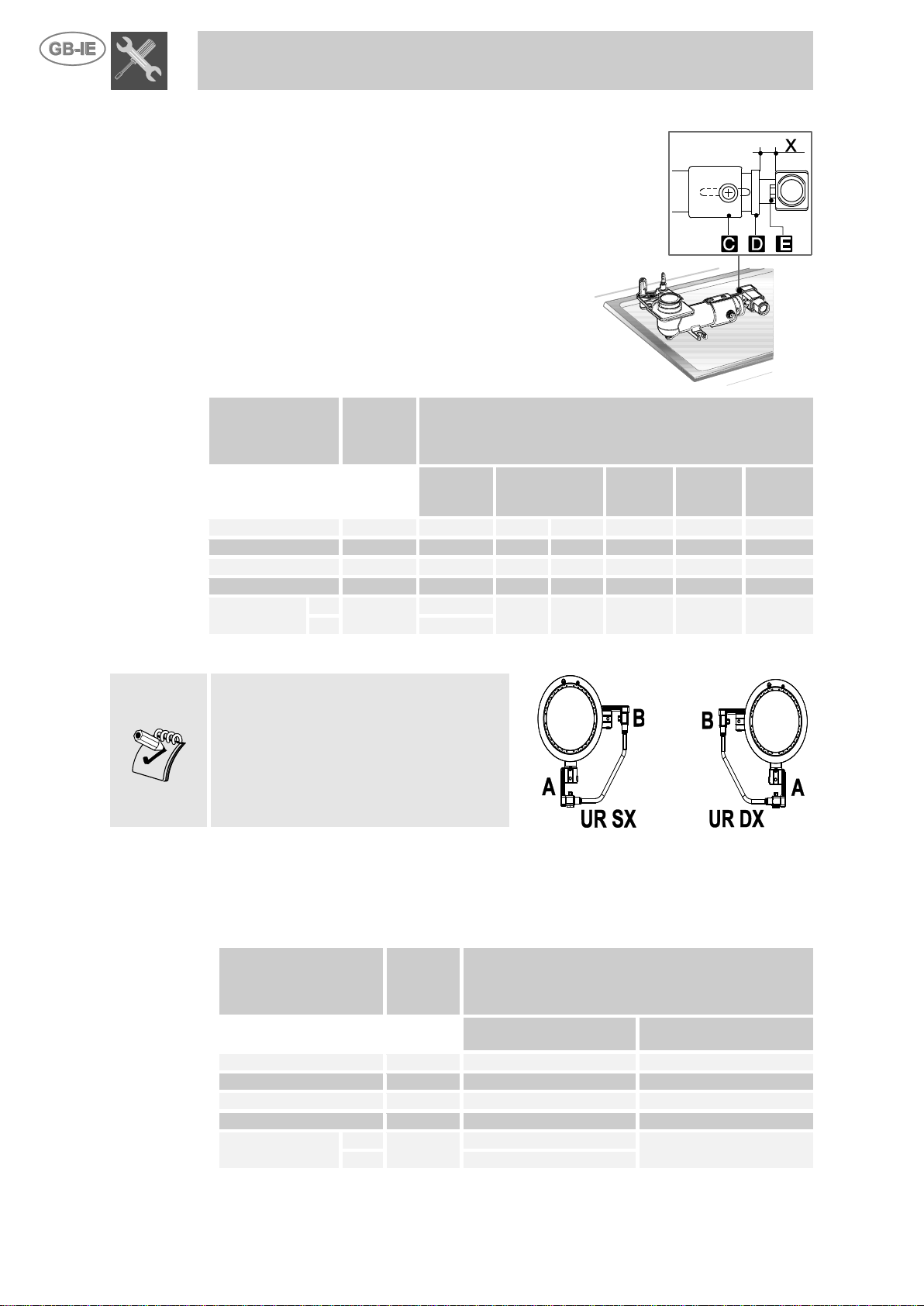

5.2 Regulation for LPG

Loosen screw C and push air regulator D to the

bottom.

With a 7 mm wrench, remove nozzle E and

replace it with the proper one (follow the

instructions on the reference tables for the type of

gas to be used). The torque wrench setting of the

nozzle must not exceed 3 Nm.

Regulate the air by sliding regulator D until

reaching distance “X” shown in the table in

paragraph “5.4 Regulation of primary air ”.

Lock regulator D by tightening screw C.

Burner

Rated

heating

capacity

(kW)

LPG – G30/G31 28/37 mbar

Nozzle

diameter

1/100 mm

By-pass

mm

1/100

Reduced

flowrate

(W)

Flowrate

g/h G30

Flowrate

g/h G31

Auxiliary

1.0

48

30(**)

33 (*)

450

73

71

Semi rapid

1.65

62

32(**)

35 (*)

500

120

118

Medium rapid

2.3

75

38(**)

43 (*)

700

167

164

Large rapid

3.0

82

42(**)

45 (*)

800

218

214

UR

A

3.6

76

48 (**)

52 (*)

1000

261

257

B

48

*/**: diameters marked * and ** must be fitted respectively on valves marked * and **shown inpoint “5.6

Regulation of minimum for natural gas”.

CAUTION: for references A and B on

the lh UR and rh UR burners, see

drawings at side.

5.3 Regulation for natural gas

The hob has been inspected for G20 (2H) natural gas at a pressure of 20 mbar. To

allow the unit to work with this type of gas, perform the same operations described in

paragraph “5.2 Regulation for LPG ”, but choose the nozzles and regulate the primary

air for natural gas, as shown in the following table and in paragraph “5.4 Regulation of

primary air ”.

Burner

Rated

heating

capacity

(kW)

Natural gas – G20 20 mbar

Nozzle diameter

1/100 mm

Reduced flowrate

(W)

Auxiliary

1.0

73

400

Semi rapid

1.65

92

500

Medium rapid

2.3

110

700

Large rapid

3.0

126

800

UR

A

3.6

115

1000

B

73

Loading ...

Loading ...

Loading ...