Loading ...

Loading ...

Loading ...

DRIVING WITH VARIABLE SPEED

The technique is to start slowly, increasing the

speed as the screw runs down. Set the screw

snug ly by slowing to a stop. Prior to driving

screws, pilot and clearance holes should be

drilled.

Always hold the machine straight on the bolt

to be tightened.

The best method to determine the right

impacting/tightening duration is by means of a

trial. For small screws, the right

impacting/tightening duration can be reached

in less then 0.5 Sec. Therefore, work with low

RPM and switch the machine off immediately

when the screw is tight and the impacting

sound can be heard.

For screwing larger, longer wood screws into

hard material, pre-drilling is the best method.

TIGHTENING TORQUE

The tightening torque depends on the duration

of the impacting/tightening action. The largest

tightening torque is achieved after approx. 6 to

10 Sec. impacting/tightening action.

The torque build-up depends on the

following factors:

• Hardness of the bolts/nuts.

• Type of washer (disk washer, spring washer,

seal).

• Hardness of the material to be joined.

• Lubricating effect at the surfaces of the

junction.

This leads to the following application cases:

Hard case: The joining of metal to metal with

a disk washer. The maximum torque is

reached after a relative short impacting/

tightening action.

Medium case: The joining of metal to metal

where spring ring washer, disk spring washer,

stud bolts or bolts/nuts with conical seats are

used.

Soft case: The joining of e.g. metal to wood

or insulation material.

For middle or soft joining cases, the maximum

tightening torque is less as for hard cases.

Therefore, a longer impacting/tightening action

is necessary to arrive at the maximum

tightening torque.

FASTENING WITH SCREWS

This procedure shown in (Fig. 7) will enable

you to fasten ma terials together with your tool

without stripping, splitting or separating the

material.

First, clamp the pieces together and drill the

first hole 2/3 the diam eter of the screw. If the

material is soft, drill only 2/3 the proper

Operating Tips

-10-

B

UILT IN WORK LIGHT

Your tool is also equipped with a light that turns

on automatically when the switch is activated,

for better visibility when drilling/driving (Fig. 1).

BATTERY CHARGE CONDITION

INDICATOR LIGHTS

Your tool is equipped with charge condition

indicator lights (Fig. 1). The indicator lights

shows the charge condition of the battery for a

f

ew second when the On/Off trigger is pressed

halfway or fully.

LED Capacity

Continuous lighting 3 x green > 2/3

Continuous lighting 2 x green > 1/3

Continuous lighting 1 x green < 1/3

Flashing light 1 x green reserve

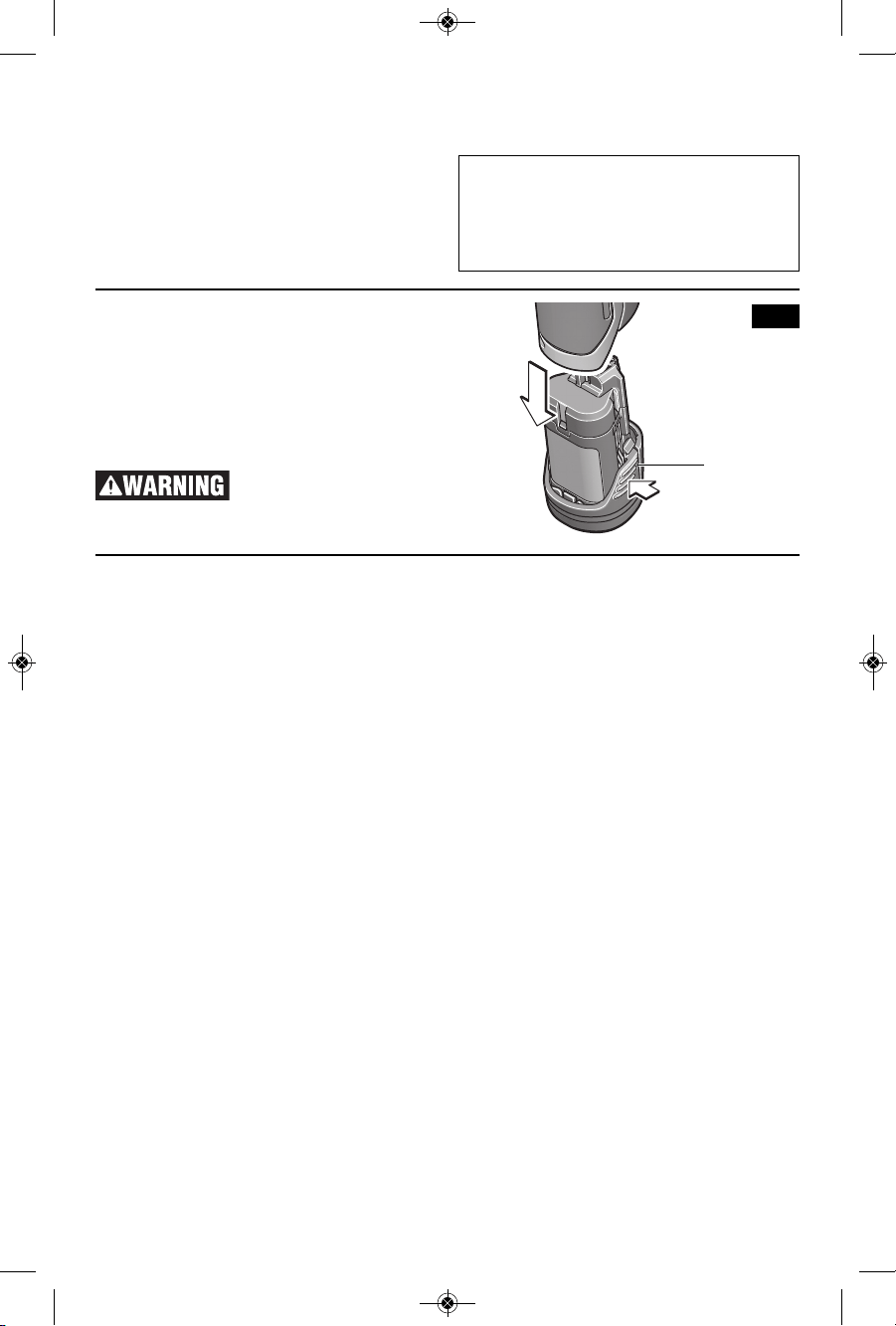

INSERTING AND RELEASING

BATTERY PACK

Release battery pack from tool by pressing on

both sides of the battery release tabs and pull

downward (Fig. 4).

To insert battery, align battery and slide

battery pack into tool until it locks into position.

Do not force.

If battery release tabs are

cracked or otherwise

damaged, do not insert into tool. Battery can

fall out during operation.

BATTERY

RELEASE

TABS

FIG. 4

2610051964_PS41 1/16/19 10:59 AM Page 10

Loading ...

Loading ...

Loading ...