Documents: Go to download!

- Owner's manual - (English, French)

- OPERATING INSTRUCTIONS

- INSTALLATION INSTRUCTIONS

- TROUBLESHOOTING

Table of contents

USER MANUAL Front-Loading Automatic Washer

OPERATING INSTRUCTIONS

Accessories

Stack Kit

If space is at a premium, the stack kit allows the dryer to be installed on top of the washer.

12" Pedestal

Color-matched pedestals raise the washer and dryer to a more comfortable working height.

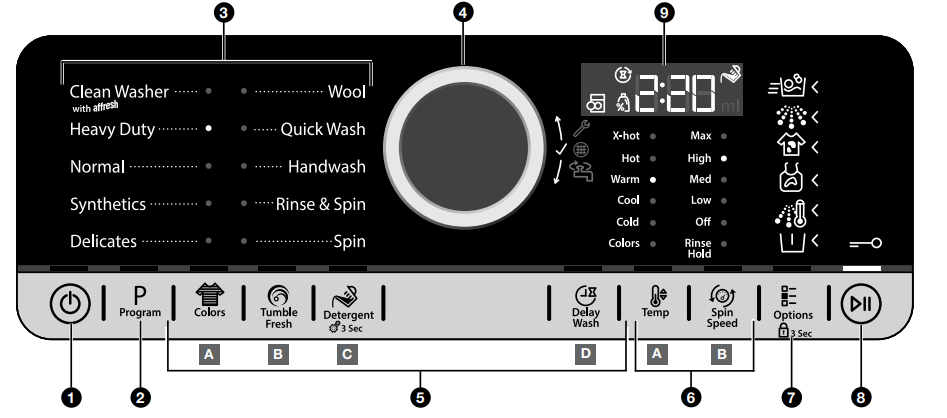

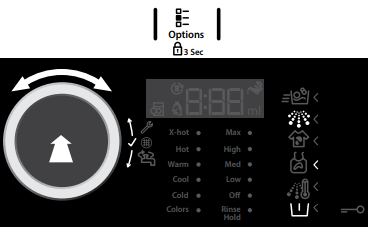

Control Panel and Features

1. POWER BUTTON

- Touch and hold until the indicator above the Program button lights up. The indicators above all the buttons will scroll from left to right as the washer turns on. Symbols appear on the control panel and sounds are played.

- Touch and hold POWER to cancel a cycle. “rES” is displayed when the cycle is cancelled.

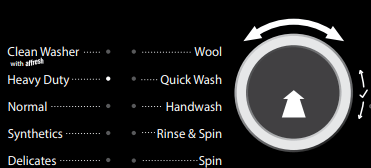

2. PROGRAM (cycle)

When you turn on the washer, the light above this button will turn on. This indicates you can now select your program or cycle. The program settings which you used last will appear on the control panel.

3. PROGRAM/CYCLE AREA

An indicator next to each program/cycle lights up as you use the knob to scroll through the list. Press the knob when the indicator next to the desired program/cycle lights up.

4. CONTROL KNOB

Turn the knob to select a program/cycle for your laundry load, change program/cycle temperature, adjust spin speed, set delay start time or dosing values, or select Other Options. Press the knob to confirm your selection.

5. OPTIONS

- Touch to select additional wash options or additional features on the washer before touching the Start/Pause button. Additional wash options or additional features selected after touching the Start/Pause button may not be activated.

- To return to factory default cycle settings, unplug the washer for 30 seconds, then plug back in.

A. Colors

- This option helps to preserve the colors of your laundry by washing them with cold water 59°F (15°C). Suitable for lightly soiled colored laundry without stains.

B. TumbleFresh™ Option

- The TumbleFresh™ option will periodically tumble the load after the end of the cycle every 3 minutes for 7 seconds, for up to 6 hours. To turn on the TumbleFresh™ option, touch the TUMBLEFRESH button. If, however, the TumbleFresh™ option is turned on, it will stay on for all future cycles until turned back off – the washer remembers the last on/off status set. To turn off the TumbleFresh™ option, touch the TUMBLEFRESH button.

C. Detergent Dosing Aid

- This option helps to determine the correct amount of detergent for your laundry load. The concentration of detergents varies considerably, so adjust the amount of detergent as needed. Also check if the washer’s preset water hardness level matches your local water hardness level and adjust it if needed (see the “Using Your Washer” section).

- When you touch this button, the Detergent Dosing Aid symbol lights up in the display.

- When you touch the Start/Pause button to start the program/cycle, the drum will rotate to detect the load size of the laundry. During load detection, the time display changes from cycle time to a chasing LED animation. The display will then show the recommended detergent amount in milliliters (see Concentration Chart in “About Detergent Concentration”). Use any standard measuring cup to measure out the right detergent amount. After adding detergent, close the detergent dispenser. Touch and hold the START/PAUSE button to continue the cycle.

D. Delay Wash

- This option starts your program/cycle at a later time, up to 24 hours.

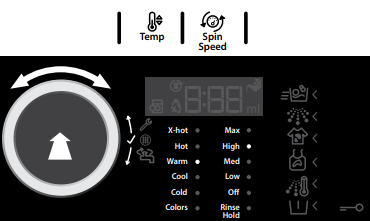

6. SETTINGS

A. Temperature

- This setting lets you change the temperature of the program/cycle selected, if desired.

B. Spin Speed

- This setting lets you change the spin speed of the program/cycle selected, if desired.

Rinse/Hold

- This option will stop at the end of the rinse portion of the cycle and leave the clothes soaking until you touch the Start/Pause button to continue the drain and final spin.

7. OTHER OPTIONS

Save Time

Save Time

- This option enables quicker washing. Only recommended for lightly soiled laundry

Extra Rinse

Extra Rinse

- This option helps to avoid detergent residues in the laundry by extending the rinse time. Especially suitable for baby laundry, people with allergies, or areas with soft water.

Heavy Soil

Heavy Soil

- This option optimizes the stain-removal efficiency of additives. Ideal for heavily soiled, stained laundry. Add an appropriate amount of powder in-wash additive for stain removal to the main wash compartment, together with your detergent (powder only). This may extend the program by up to 15 minutes. Appropriate for use with oxygen-based stain removers.

Cold Water PreWash for Stains

Cold Water PreWash for Stains

- This option helps remove all kinds of stains (except grease/oil) by beginning with a cold water wash and adding 10 minutes to the cycle.

Warm Rinse

Warm Rinse

- This option ends with a warm rinse. This rinse relaxes the fibers of your laundry to make it feel comfortably warm when removed soon after the program/cycle ends.

PreWash

PreWash

- This option helps to clean heavily soiled laundry by adding a 20-minute prewash to the program/cycle selected.

Control Lock

Control Lock

- This option allows you to lock the buttons and knob to avoid unwanted use by small children or other unqualified persons. Touch and hold the OPTION button until the “key” symbol lights up. All controls will be locked except for the Power button. To cancel Key Lock, touch and hold the OPTION button until the key symbol goes off.

8. START/PAUSE BUTTON

- Touch to start, or touch and hold to pause, a program/ cycle. When you start a program/cycle, the display shows an animation of chasing LEDs. This indicates the washer is estimating dry load size. Once the load size is estimated, water will be added to start the wash cycle.

9. LED DISPLAY

- When you select a program/cycle, its default settings will light up and the Estimated Time Remaining will be displayed. Factors such as load size, wash temperature, and water pressure may affect the time shown in the display. Tightly packing, unbalanced loads, or excessive suds may cause the washer to lengthen the program/cycle time, as well.

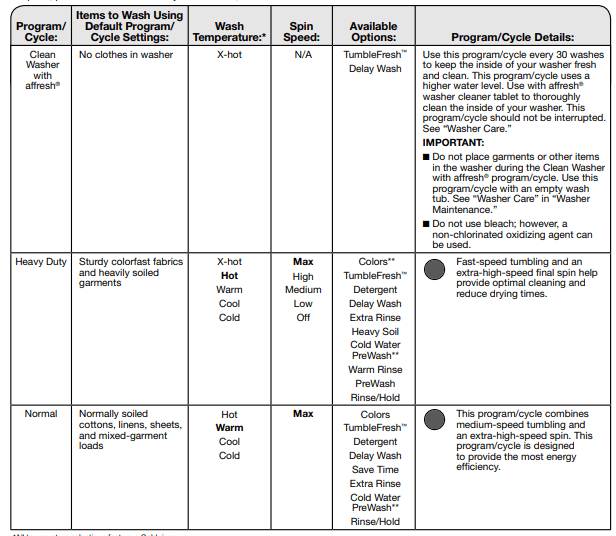

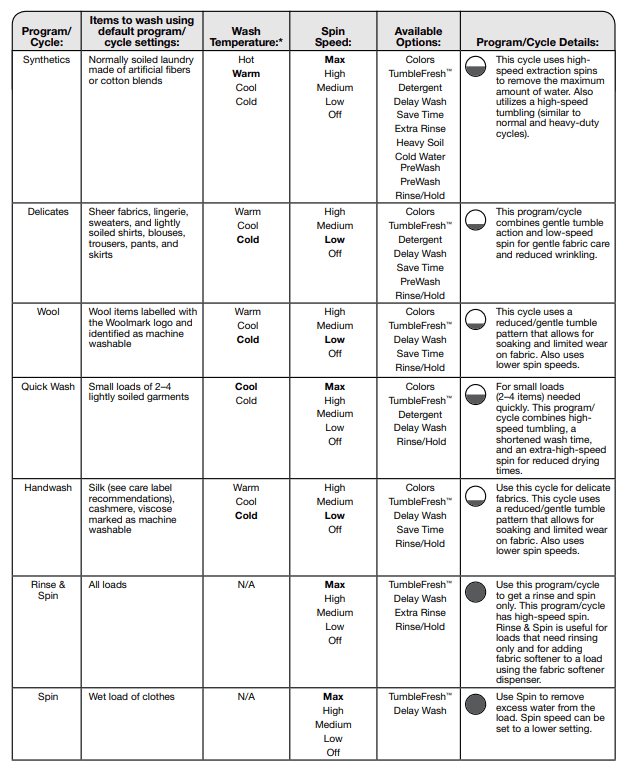

Program/Cycle Guide

Settings and options shown in bold are default settings for that program/cycle. For best fabric care, choose the program/cycle, options, and settings that best fit the load being washed. Not all settings are available with each program/cycle, and some options cannot be used together.

Load Size Recommendations

For best results, follow the load size recommendations noted for each program/cycle.

Small load: Fill the washer drum with 3–4 items, not more than 1/4 full.

Small load: Fill the washer drum with 3–4 items, not more than 1/4 full.

Medium load: Fill the washer drum up to about 1/2 full.

Medium load: Fill the washer drum up to about 1/2 full.

Large load: Fill the washer drum up to about 3/4 full.

Large load: Fill the washer drum up to about 3/4 full.

Extra-large load: Fill the washer drum, but make sure clothes can tumble freely. For best results, avoid packing tightly

Extra-large load: Fill the washer drum, but make sure clothes can tumble freely. For best results, avoid packing tightly

Rinse Hold Option

This option keeps laundry in the final rinse water without spinning. Rinse Hold is suitable for delicate laundry and items that require a lower spin speed, but is not appropriate for silk.

To turn off Rinse Hold and drain the water:

- Turn the knob to select “0” for spin speed, press the knob to confirm your selection, and touch the START/PAUSE button.

OR

- Spin the laundry, if desired. Touch the START/PAUSE button to spin at the default speed or turn the knob to select a different spin speed, press the knob to confirm your selection, and touch the START/PAUSE button.

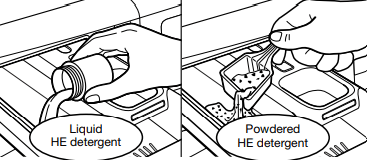

Choosing the Right Detergent

Use only High Efficiency detergents. The package will be marked “HE” or “High Efficiency.” Low-water washing creates excessive sudsing with a non-HE detergent. Using non-HE detergent will likely result in longer cycle times and reduced rinsing performance. It may also result in component malfunction and, over time, buildup of mold or mildew. HE detergents should be low-sudsing and quick-dispersing to produce the right amount of suds for the best performance. They should hold soil in suspension so it is not redeposited onto clean clothes. Not all detergents labeled as High Efficiency are identical in formulation and their ability to reduce suds. For example, natural, organic, or homemade HE detergents may generate a high level of suds. Always follow the detergent manufacturer’s instructions to determine the amount of detergent to use.

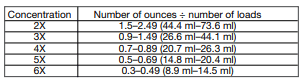

About Detergent Concentration

- Today’s liquid HE detergents are concentrated. Most brands of concentrated HE detergent will show the level of concentration on the bottle.

- However, if the detergent bottle does not give the concentration, it can be easily calculated. Just divide the package size in fluid ounces by the number of loads. Then refer to the chart below to find the concentration.

- If you do not get your desired cleaning results, try using a lower concentration number. If you have excess suds, try using a higher concentration number

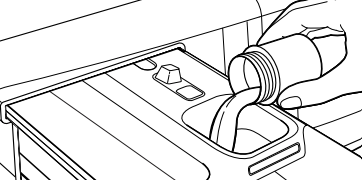

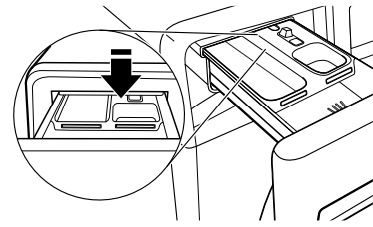

Using the Dispenser Drawer

- Open the dispenser drawer.

- Add laundry products as described in steps 4–6 in the “Using Your Washer” section.

- Slowly close the dispenser drawer. Make sure it is completely closed.

NOTE: A small amount of water may remain in the dispensers from the previous wash cycle. This is normal.

IMPORTANT: Do not use chlorine bleach in this washer.

Using Your Washer

First wash cycle without laundry

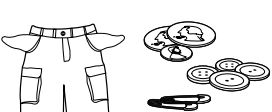

1. Sort and prepare your laundry

Sort items by recommended cycle, water temperature, and colorfastness. Separate heavily soiled items from lightly soiled. Separate delicate items from sturdy fabrics. Treat stains promptly and check for colorfastness by testing stain remover products on an inside seam.

IMPORTANT:

- Empty pockets. Loose change, buttons, or any small object can plug pumps and may require a service call.

- Close zippers, fasten hooks, tie strings and sashes, and remove non-washable trim and ornaments.

- Mend rips and tears to avoid further damage to items during washing.

- Turn knits inside out to prevent pilling. Separate lint-takers from lint-givers. Synthetics, knits, and corduroy fabrics will pick up lint from towels, rugs, and chenille fabrics.

- Do not dry garments if stains remain after washing, because heat can set stains into fabric.

- Always read and follow fabric care labels and laundry product instructions. Improper usage may cause damage to your garments.

2. Add laundry products (if desired)

Single-dose laundry packets, Oxi-type boosters, or fabric softener crystals can be added to the drum prior to adding laundry.

NOTES:

- Always follow manufacturer’s instructions.

- Do not use chlorine bleach.

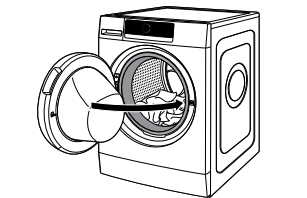

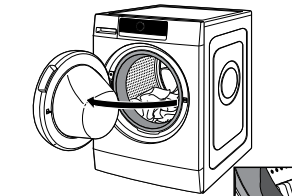

3. Load laundry into washer

Place a load of sorted items loosely in the washer. Items need to move freely for best cleaning and to reduce wrinkling and tangling. Close the washer door by pushing it firmly until the latch clicks.

- Depending on load type and cycle, the washer can be fully loaded, but not tightly packed. Washer door should close easily. See “Program/Cycle Guide” for loading suggestions.

- Mix large and small items and avoid washing single items. Load evenly.

- Wash small items in mesh garment bags. For multiple items, use more than one bag and fill bags equally

4. Add HE detergent*

NOTE: Do not add single-dose laundry packets, Oxi-type boosters, or fabric softener crystals to dispensers. They will not dispense correctly

5. Add liquid fabric softener to dispenser (if desired)

- Pour a measured amount of liquid fabric softener into liquid fabric softener compartment. Always follow manufacturer’s directions for correct amount of fabric softener based on your load size.

- Fabric softener is always dispensed in the last rinse, even if Extra Rinse is selected.

IMPORTANT: Do not overfill, dilute, or use more than 1/4 cup (60 mL) of fabric softener. Do not fill past the MAX line. Overfilling dispenser will cause fabric softener to immediately dispense into washer.

- Do not spill or drip any fabric softener onto the clothes.

- Do not use liquid fabric softener dispenser balls in this washer. They will not dispense correctly

6. Touch and hold POWER button to turn on washer

- Touch and hold until the indicators turn on.

NOTE: To cancel a cycle, touch and hold the POWER button. “rES” is displayed when the cycle is cancelled.

NOTE: When powering on the washer, the indicator lights will scroll across the front of the control panel. Do not try to program the washer until the lights stop scrolling.

7. Select program/cycle†

Turn the knob to select a program/cycle for your laundry load. As you turn the knob, an indicator light will light up next to the program/cycle names to the left of the knob. Stop turning when the indicator next to the desired program/cycle lights up. Press the knob to confirm your selection

8. Select options, if desired†

Dosing Aid (Detergent Button):

The Detergent button calculates a recommended amount of detergent in milliliters. This will be displayed after touching the Start/Pause button and the load is detected. The Detergent button also lets you adapt your washer to the dosing amounts of your detergent and the hardness of your local water.

To set the washer for the detergent dosing amount:

- Check your detergent dosing amount for medium soil level and medium water hardness.

- Touch and hold the DETERGENT button until the bottle symbol on the display lights up.

- Turn the knob to adjust the dosing value to the one shown on the detergent bottle. Press the knob to confirm your selection. See the chart in “About Detergent Concentration.”

To set the washer for local water hardness (washer is preset for soft water):

- Check your regional water hardness level by consulting your local authorities or the Internet.

- If your water is not soft, touch and hold the PROGRAM and DETERGENT buttons at the same time. “1” (for soft water) appears on the display

- Turn the knob to adjust the water level to either “2” (Medium) or “3” (Hard). Press the knob to confirm your selection.

9. Setting a delayed wash, if desired†

If you do not want to begin a cycle immediately, you may choose the Delay Wash option. This will delay the start of the wash cycle by up to 24 hours.

To set a Delayed Wash:

- Touch the DELAY WASH button to set the desired delay time.

- Turn the knob to the number of hours you want to delay the start of the wash cycle. The delay time will appear on the display. Press the knob to confirm your selection.

After touching the Start/Pause button, the door will lock and the time will count down until the delay time has been reached. The washer will start and the display will show the remaining time in the cycle.

10. Change temperature or spin speed, if desired†

Touch the TEMP or SPIN SPEED button; then turn the knob to select the desired temperature or spin speed. As you turn the knob, an indicator light will light up next to the temperatures or spin speeds to the right of the knob. Stop turning when the indicator next to the desired selection lights up. Press the knob to confirm your selection.

11. Select any additional options†

After setting temperature or spin speed, the light above “Options” lights up. Turn the knob to select the desired option(s). As you turn the knob, the option symbols above the Options button will light up one at a time as you turn the knob. Stop turning when the symbol of the desired option lights up. Press the knob to confirm your selection.

12. Touch START/PAUSE button to begin wash program/cycle

- Touch the START/PAUSE button to start the wash program/ cycle. To pause a program/cycle in progress, touch the START/PAUSE button once, then touch again to continue the program/cycle. To cancel a program/cycle, touch the POWER button.

- Once you touch the START/PAUSE button, you will hear the door lock. The washer door will remain locked during the wash program/cycle.

13. Touch POWER button to turn off washer after program/cycle ends

14. Remove garments promptly after cycle is finished

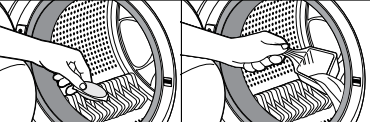

- Promptly remove garments after cycle has completed to avoid odor and rusting of metal objects on garments. When unloading garments, pull back the door seal and check for small items between the tub and the washer drum

- . If you will be unable to remove the load promptly, use the TumbleFresh™ option. If the TumbleFresh™ option is selected, the washer will automatically tumble the load periodically for up to 6 hours. To turn off the TumbleFresh™ option, touch the POWER button. To set the washer so that the TumbleFresh™ option does not come on for future cycles, touch the TUMBLEFRESH button.

NOTES:

- The door will remain locked while the TumbleFresh™ option is active. To cancel the option and unlock the door, touch the POWER button.

- A small amount of water may remain in the dispensers after the wash cycle is complete. This is normal.

- This washer has a tight seal to avoid water leaks. To avoid odors, leave the door open to allow the washer to dry between uses.

Washer Maintenance

WATER INLET HOSE

Replace inlet hose after five years of use to reduce the risk of hose failure. Periodically inspect and replace inlet hose if bulges, kinks, cuts, wear, or leaks are found. When replacing your inlet hose:

- Mark the date of replacement on the label with a permanent marker.

- Check that the old washer is not stuck on the washer inlet valve.

- Use a new washer in the new inlet hose to ensure a proper seal.

WASHER CARE

Recommendations to Help Keep Your Washer Clean and Performing at Its Best

- Always use High Efficiency (HE) detergents and follow the HE detergent manufacturer’s instructions regarding the amount of HE detergent to use. Never use more than the recommended amount because that may increase the rate at which detergent and soil residue accumulate inside your washer, which in turn may result in undesirable odor.

- Use warm or hot water washes sometimes (not exclusively cold water washes), because they do a better job of controlling the rate at which soils and detergent accumulate.

- Always leave the washer door slightly ajar between uses to help dry out the washer and avoid the buildup of odor-causing residue.

- Periodically clean residue from all interior surfaces of the glass window. For better care, wipe the entire inside of the glass door with a damp cloth.

Cleaning Your Front-Loading Washer

- Read these instructions completely before beginning the routine cleaning processes recommended below. This Washer Maintenance Procedure should be performed, at a minimum, once per month or every 30 wash cycles, whichever occurs sooner, to control the rate at which soils and detergent may otherwise accumulate in your washer.

Cleaning the Door Seal

- Open the washer door and remove any clothing or items from the washer.

- Inspect the seal between the door opening and the drum for stained areas or soil buildup. Pull back the seal to inspect all areas under the seal and to check for foreign objects.

- If stained areas or soil buildup are found, wipe down these areas of the seal using the following procedure: When the cycle is complete, gently pull back the rubber door seal and clean the entire surface with the textured side of an affresh® Machine Cleaning Wipe.

Cleaning the Inside of the Washer

- This washer has a special cycle that uses higher water volumes in combination with affresh® Washer Cleaner to thoroughly clean the inside of the washer. Steam washer models also utilize steam to enhance cleaning in this special cycle.

NOTE: Read these instructions completely before beginning the cleaning process.

Begin procedure

Clean Washer with affresh® Cycle Procedure (Recommended for Best Performance):

a. Open the washer door and remove any clothing or items.

b. Use an affresh® Machine Cleaning Wipe or a soft, damp cloth or sponge to clean the inside door glass.

c. Add an affresh® Washer Cleaner tablet to the washer drum.

d. Do not add the affresh® Washer Cleaner tablet to the dispenser drawer.

e. Do not add any detergent or other chemical to the washer when following this procedure.

f. Close the washer door.

g. Select the Clean Washer with affresh® cycle.

h. Select the TumbleFresh™ option to help dry the washer interior after the cycle is complete.

NOTE: The washer remembers your last option selection and will use it for future wash cycles until you deselect that option.

i. Touch the START/PAUSE button to begin the cycle. The Clean Washer with affresh® Cycle Operation is described below.

Description of Clean Washer with affresh® Cycle Operation:

- Do not run this cycle with a load. Doing so could damage the items.

- After the cycle is complete, leave the door open slightly to allow for better ventilation and drying of the washer interior.

Cleaning the Dispensers

- After a period of using your washer, you may find some residue buildup in the washer’s dispensers. To remove residue from the dispensers, remove the drawer and wipe the surfaces with an affresh® Machine Cleaning Wipe or a damp cloth and towel dry either before or after you run the Clean Washer with affresh® cycle. Use an all-purpose surface cleaner, if needed.

IMPORTANT: Dispenser is not dishwasher safe.

Cleaning the Outside of the Washer

- Use an affresh® Machine Cleaning Wipe or a soft, damp cloth or sponge to wipe up any spills. Occasionally wipe the outside of your washer to help keep it looking new. Use an affresh® Machine Cleaning Wipe or mild soap and water.

IMPORTANT: To avoid damaging the washer’s finish, do not use abrasive products.

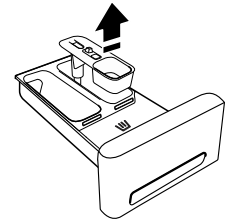

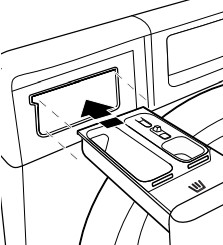

REMOVING THE DISPENSER

To remove:

- Pull dispenser drawer out until it stops.

- Press down on the release tab and pull straight out to remove the dispenser.

- Lift off cover panel by pulling straight up.

To replace:

- Slide cover panel back onto posts on dispenser.

- Align edges of dispenser with guides in washer, then slide dispenser back into slot.

NON-USE AND VACATION CARE

Operate your washer only when you are home. If moving, or not using your washer for a period of time, follow these steps:

- Unplug or disconnect power to washer.

- Turn off water supply to washer to avoid flooding due to water pressure surges. HELPFUL TIP: Attach a reminder note to the washer to turn the water back on before washer’s next use.

- Clean the dispensers. See “Cleaning the Dispensers.”

WINTER STORAGE CARE

IMPORTANT: To avoid damage, install and store washer where it will not freeze. Because some water may stay in hoses, freezing can damage washer. If storing or moving during freezing weather, winterize your washer.

To winterize washer:

- Shut off water faucet, disconnect and drain water inlet hose. HELPFUL TIP: Attach a reminder note to the washer to turn the water back on before washer’s next use.

- Put 1 qt. (1 L) of R.V.-type antifreeze in washer drum and run washer on Normal cycle for about 2 minutes to mix antifreeze and remaining water.

- Unplug washer or disconnect power.

TRANSPORTING YOUR WASHER

- Shut off water faucet. Disconnect and drain water inlet hose.

- If washer will be moved during freezing weather, follow “Winter Storage Care” directions before moving.

- Disconnect drain hose from drain system and from back of washer.

- Unplug power cord.

- Place inlet hose and drain hose inside washer drum.

- Bundle power cord with a rubber band or cable tie to keep it from hanging onto the ground.

IMPORTANT: Call for service to install new transport bolts. Do not reuse transport bolts. Washer must be transported in the upright position. To avoid structural damage to your washer, it must be properly set up for relocation by a certified technician.

REINSTALLING/USING WASHER AGAIN

To reinstall washer after non-use, vacation, winter storage, or moving:

- Refer to “Installation Instructions” to locate, level, and connect washer.

- Before using again, run washer through the following recommended procedure:

To use washer again:

- Flush water pipes and hose. Reconnect water inlet hose. Turn on water faucet.

- Plug in washer or reconnect power.

- Run washer through Heavy Duty cycle to clean washer and remove antifreeze, if used. Use only HE detergent. Use half the manufacturer’s recommended amount for a medium-size load.

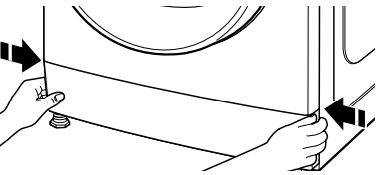

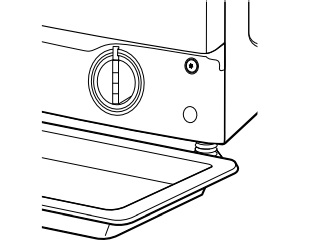

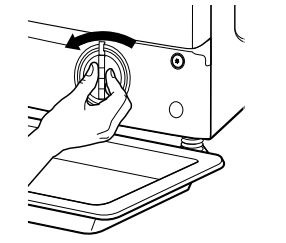

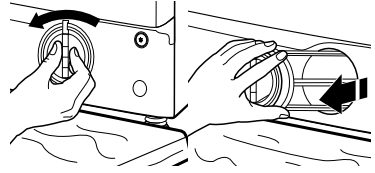

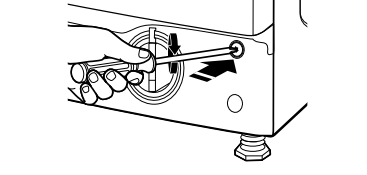

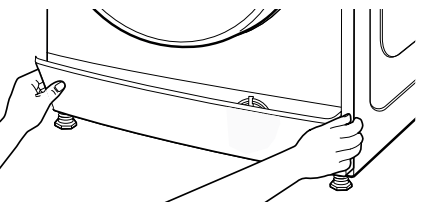

CLEANING THE DRAIN PUMP FILTER/ DRAINING RESIDUAL WATER

- Push the tabs located on both sides of the base panel to release it, then remove

- Place a broad, flat container beneath the drain pump filter to collect the drain water.

- Slowly turn the filter counterclockwise until water flows out. Let the water flow out, without removing the filter. When the container is full, close the drain pump filter by turning it clockwise. Empty the container. Repeat this procedure until all the water has drained.

- Lay a cotton cloth beneath the drain pump filter to absorb any water still in it. Then remove the drain pump filter by turning it counterclockwise.

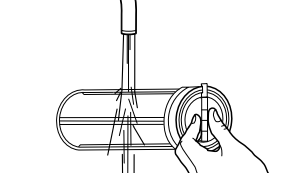

- Remove residue from the filter by rinsing with water.

- Reinsert the drain pump filter by turning it clockwise. Make sure to turn it in as far as it will go, with the filter handle left in a vertical position. To test water tightness of the drain pump filter, pour about 1 liter of water into the detergent dispenser. Then reinstall the base panel.

INSTALLATION INSTRUCTIONS

Installation Requirements

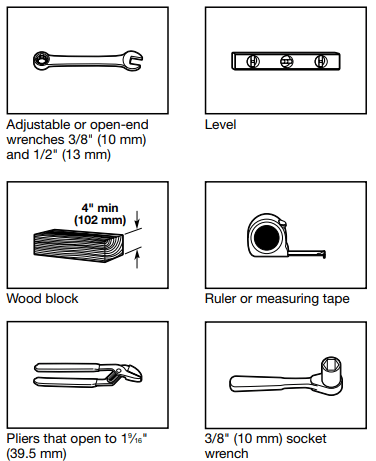

Tools needed:

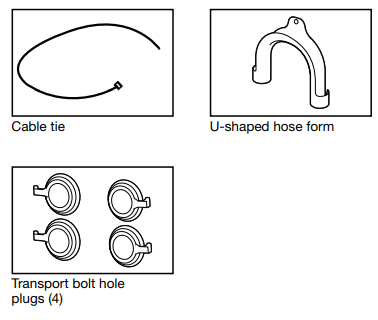

Parts supplied:

NOTE: All parts supplied for installation are in the washer drum. Inlet hoses and washers are not included.

Optional tools:

Location Requirements

You will need:

- A grounded electrical outlet located within 5.4 ft (1.7 m) of power cord on back of washer.

- Water faucet located within 4 ft (1.2 m) of water fill valve on washer, and water pressure of 20–100 psi (137.9–689.6 kPa).

- A level floor with maximum slope of 1" (25 mm) under entire washer. Installing on carpet or surfaces with foam backing is not recommended.

- Floor must support washer’s total weight (with water and load) of 400 lbs (180 kgs).

IMPORTANT: Do not install, store, or operate washer where it will be exposed to weather or in temperatures below 32°F (0°C). Water remaining in washer after use may cause damage in low temperatures. See “Washer Maintenance” for winterizing information.

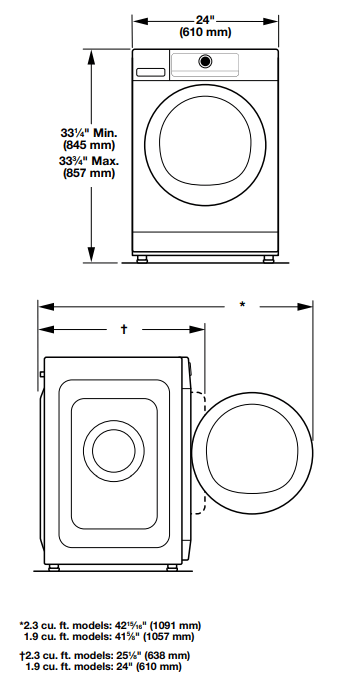

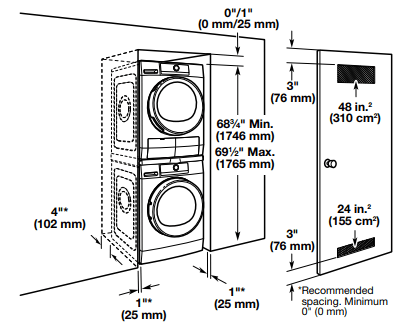

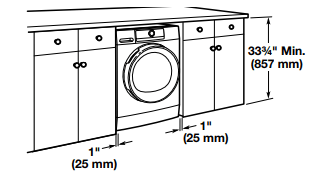

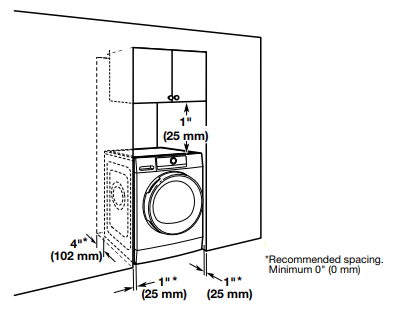

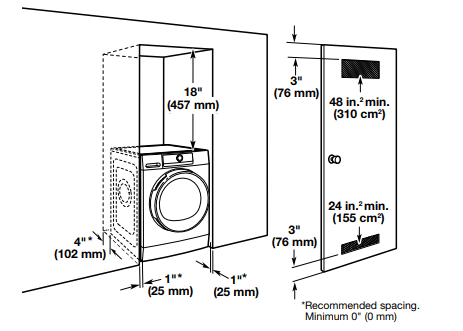

- All dimensions show recommended spacing allowed, except for closet door ventilation openings which are the minimum required.

- For each arrangement, consider allowing more space for ease of installation and servicing, and spacing for companion appliances and clearances for walls, doors, and floor moldings.

- Space must be large enough to allow door to fully open. Add spacing of 1" (25 mm) on all sides of washer to reduce noise transfer. If a closet door or louvered door is installed, top and bottom air openings in door are required.

Recessed area or closet installation (stacked washer and dryer):

Custom under counter installation:

IMPORTANT: When installing under a counter with a dryer, refer to dryer installation instructions for space requirement.

Custom cabinet installation:

Closet installation (washer only):

Drain System

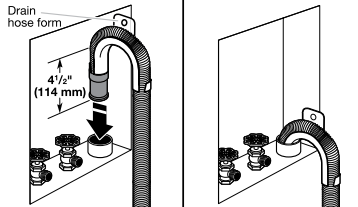

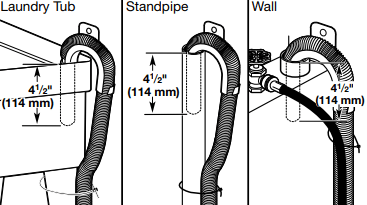

Drain system can be installed using a floor drain, wall standpipe, floor standpipe, or laundry tub. Select method you need.

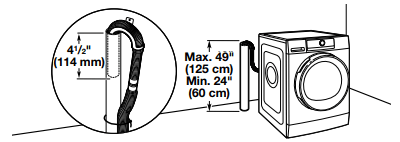

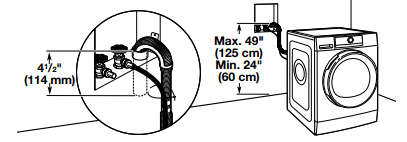

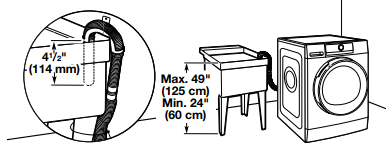

IMPORTANT: To avoid siphoning, only 41 ⁄2" (114 mm) of drain hose should be inside standpipe. Always secure drain hose with cable tie.

Floor standpipe drain system

Minimum diameter for a standpipe drain: 2" (51 mm). Minimum carry-away capacity: 17 gal. (64 L) per minute. A 1/4" (6 mm) diameter to 1" (25 mm) diameter Standpipe Adapter Kit is available (Part Number 3363920). Top of standpipe must be at least 24" (60 cm) high; install no higher than 49" (125 cm) from bottom of washer. If you have an overhead sewer and need to pump higher than 96 inches, a sump pump and associated hardware are needed. See “Alternate Parts.”

Wall standpipe drain system

See requirements for floor standpipe drain system.

Laundry tub drain system

Minimum capacity: 20 gal. (76 L). Top of laundry tub must be at least 24" (60 cm) above floor; install no higher than 49" (125 cm) from bottom of washer.

Floor drain system

Floor drain system requires a Siphon Break Kit (Part Number 285834), two Connector Kits (Part Number 285835), and an Extension Drain Hose (Part Number 285863) that may be purchased separately. See “Alternate Parts.” Minimum siphon break height: 28" (710 mm) from bottom of washer. (Additional hoses may be needed.)

Electrical Requirements

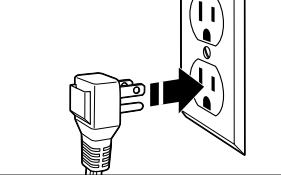

- A 120-volt, 60 Hz., AC-only, 15- or 20-amp, fused electrical supply is required. A time-delay fuse or circuit breaker is recommended. It is recommended that a separate circuit breaker serving only this appliance be provided.

- This washer is equipped with a power supply cord having a 3 prong grounding plug.

- To minimize possible shock hazard, the cord must be plugged into a mating, 3 prong, grounding-type outlet, grounded in accordance with local codes and ordinances. If a mating outlet is not available, it is the personal responsibility and obligation of the customer to have the properly grounded outlet installed by a qualified electrician.

- If codes permit and a separate ground wire is used, it is recommended that a qualified electrician determine that the ground path is adequate.

- Do not ground to a gas pipe.

- Check with a qualified electrician if you are not sure the washer is properly grounded.

- Do not have a fuse in the neutral or ground circuit.

Installation Instructions

NOTE: To avoid floor damage, set washer onto cardboard before moving it.

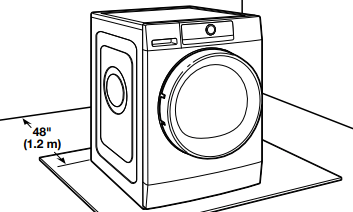

1. Move washer

- It is necessary to remove all shipping materials for proper operation and to avoid excessive noise from washer.

- Move washer to within 48" (1.2 m) of its final location. It must be in a fully upright position.

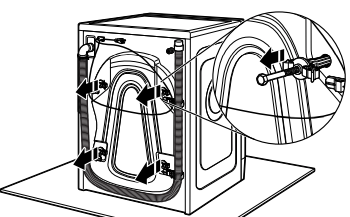

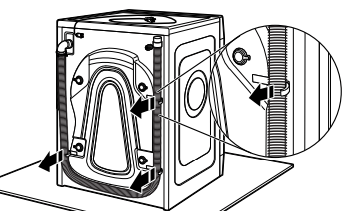

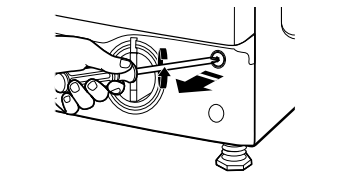

2. Remove transport bolts from washer

Loosen bolts with a 3/8" (10 mm) wrench. Once the bolt is loose, wiggle and completely pull out the bolt and shipping plug.

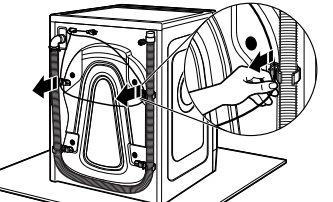

3. Remove power cord from clips

- Remove power cord from clips and place over top of washer to allow free access to back of washer.

NOTE: If washer is transported at later date, call your local service center. To avoid suspension and structural damage, a certified technician must properly set up washer for relocation.

IMPORTANT: Do not plug washer in until installation has been completed.

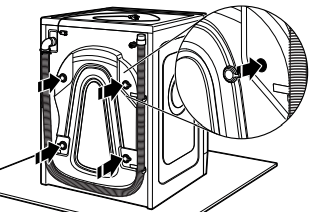

4. Cover bolt holes with transport bolt hole plugs

Close bolt holes on cabinet back with four transport bolt hole plugs included with washer parts.

Route Drain Hose

Proper routing of the drain hose protects your floor from damage due to water leakage. Read and follow these instructions.

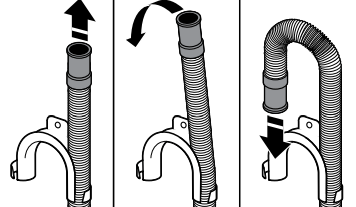

5. Remove drain hose from washer

Gently pull the corrugated drain hose from the shipping clips.

6. Connect laundry tub drain or standpipe drain hose form (floor drain installations only)

For floor drain installations, you will need to connect the drain hose form to the end of the drain hose. You may need additional parts with separate directions. See “Alternate Parts.”

7. Place drain hose in standpipe

- Place hose into standpipe (shown in picture) or over side of laundry tub.

IMPORTANT: Only 41 ⁄2" (114 mm) of drain hose should be inside standpipe; do not force excess hose into standpipe or lay on bottom of laundry tub. Drain hose form must be used.

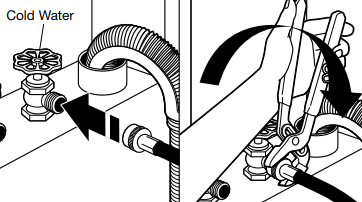

Connect Inlet Hose

- Washer must be connected to the cold water faucet with a new inlet hose with a flat washer. Do not use the old hose.

NOTE: Hose must be attached and have water flowing to inlet valve.

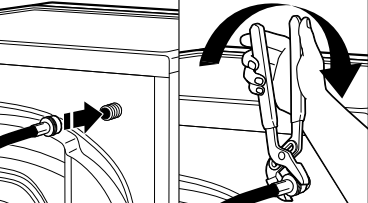

8. Connect inlet hose to water faucet

- Attach hose to cold water faucet. Screw on coupling by hand until it is seated on washer. Use pliers to tighten couplings an additional two-thirds turn.

IMPORTANT: Do not overtighten or use tape or sealants on valve when attaching to faucet or washer. Damage can result.

9. Clear water line

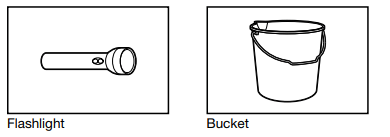

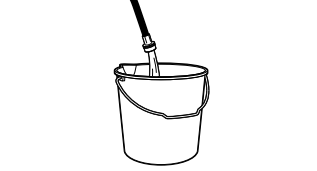

Run water for a few seconds through hose into a laundry tub, drainpipe, or bucket to avoid clogs. Water should run until clear.

10. Connect inlet hose to washer

- Attach water hose to water inlet valve. Screw coupling by hand until it is snug. Use pliers to tighten coupling an additional two-thirds turn.

IMPORTANT: To reduce risk of hose failure, replace the hose every 5 years. Record hose installation or replacement dates for future reference.

- Periodically inspect and replace hose if bulges, kinks, cuts, wear, or leaks are found.

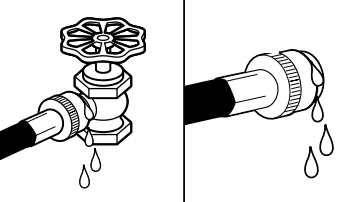

11. Check for leaks

Slowly turn on water faucet to check for leaks. A small amount of water may enter washer. It will drain later.

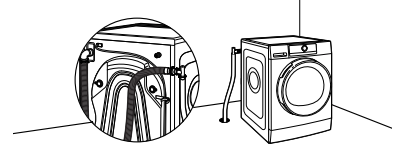

12. Secure drain hose

Secure drain hose to laundry tub leg, drain standpipe, or inlet hose for wall standpipe with cable tie.

Level Washer

Leveling your washer properly reduces excess noise and vibration.

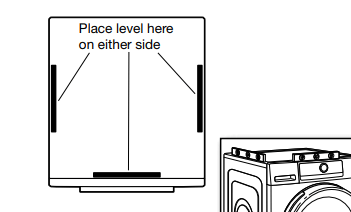

13. Check levelness of washer

Remove cardboard from beneath washer. Place a level on top edges of washer, checking each side and front. If not level, tip washer and adjust feet up or down as shown in steps 15 and 16, repeating as necessary.

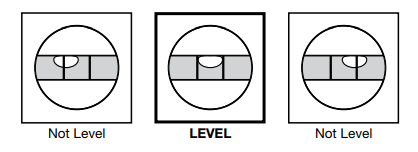

14. Rock washer to test foot contact

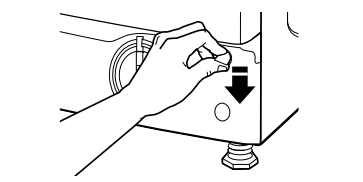

Grip washer from top and rock back and forth, making sure all four feet are firmly on floor. Repeat, rocking washer from side to side. If washer rocks, go to Step 15 and adjust leveling feet. If all four feet are in firm contact with floor, go to Step 17.

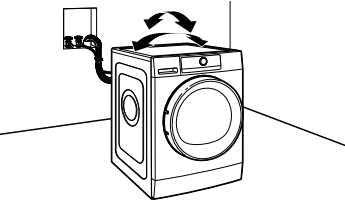

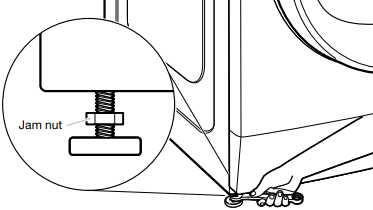

15. Adjust leveling feet

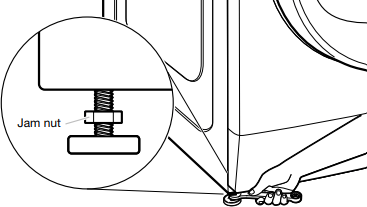

- If washer is not level, use a 1/2" (13 mm) open-end or adjustable wrench to turn jam nuts clockwise on feet until they are about 1/2" (13 mm) from the washer cabinet. Then turn the leveling foot clockwise to lower the washer or counterclockwise to raise the washer. Recheck levelness of washer and that all four feet are firmly in contact with the floor. Repeat as needed.

HELPFUL TIP: You may want to prop up front of washer about 4" (102 mm) with a wood block or similar object that will support weight of washer.

16. Tighten leveling feet

- When washer is level and all four feet are firmly in contact with the floor, use a 1/2" (13 mm) open-end or adjustable wrench to turn jam nuts counterclockwise on leveling feet tightly against washer cabinet.

HELPFUL TIP: You may want to prop washer with wooden block.

17. Plug into a grounded 3 prong outlet

Complete Installation Checklist

- Check electrical requirements. Be sure you have correct electrical supply and recommended grounding method.

- Check that all parts are now installed. If there is an extra part, go back through steps to see what was skipped.

- Check that you have all of your tools.

- Check that transport bolts were completely removed from back of washer. q Check that hose is attached and water faucet is on.

- Check for leaks around faucet, valve, and inlet hose.

- Remove any tape remaining on washer.

- Check that washer is plugged into a grounded 3 prong outlet.

- Dispose of/recycle all packaging materials.

- Read “Using Your Washer.”

- To test and clean your washer, turn on the washer and choose the Normal cycle and run it without clothes. Use only HE detergent. Use 1/2 the manufacturer’s recommended amount for a medium-size load.

TROUBLESHOOTING

Error Code Appears in Display

Once any possible issues are corrected, touch the POWER button once to clear the code. Re-select and restart the cycle.

Water tap closed

Possible Causes

No or not sufficient water supply because:

- Water faucet is closed.

- There are kinks in inlet hose.

- Water faucet pressure is too low.

- Mesh filters in inlet hose are clogged.

- Water inlet hose is frozen up.

Solution

- Open the water faucet.

- Make sure there are no kinks in the inlet hose.

- Make sure water pressure is sufficient.

- Clean the mesh filters in the inlet hose.

- Install the washer at an ambient temperature of at least 41°F (5°C).

- After the problem has been corrected, touch the START/ PAUSE button. If the problem persists, touch and hold the POWER button for at least 3 seconds.

Clean filter

Possible Causes

Waste water is not pumped out because:

- There are kinks in drain hose.

- Drain hose is blocked or frozen up.

- Filter is blocked.

- Pump is blocked.

Solution

- Check the drain hose for kinks.

- Install the washer at an ambient temperature of at least 41°F (5°C).

- Clean the drain pump filter as described in the “Cleaning the Drain Pump Filter/Draining Residual Water” section.

- After the problem has been corrected, touch the START/ PAUSE button. If the problem persists, touch and hold the POWER button for at least 3 seconds.

Door open indicator blinks

Possible Causes

- The door cannot lock

Solution

- Firmly press the door in the area of the door lock to properly close it. Then touch the START/PAUSE button. If the problem persists, touch and hold the POWER button for at least 3 seconds.

FdL (or F29)

Possible Causes

- The door cannot unlock.

Solution

- Firmly press the door in the area of the door lock. Then touch and hold the POWER button for at least 3 seconds. If the Hot cycle is selected, wait until cool down and touch and hold the POWER button again for at least 3 seconds. Turn on the washer. If the failure still appears, check and eventually correct the possible cause as indicated for the “Clean filter” error code. Then turn on the washer again. If the door does not unlock, touch and hold the POWER button for at least 3 seconds.

- If the door still does not unlock, refer to the “How to Open Door in Case of Failure” section. Before draining water/ opening the door, wait until the water has cooled down (for hot wash programs).

Fod

Possible Causes

- Excessive foam formation (maybe by overdosage of detergent) interrupted the program/cycle. This interruption may be repeated several times until foam is adequately reduced.

Solution

- Start the Rinse & Spin program, with the Intensive Rinse option. Follow the detergent manufacturer’s dosing recommendations.

- Use the Dosing Aid option.

- Make sure the drain pump filter is clean.

F20 or F60

Possible Causes

- Failure of an electronic component.

Solution

- Turn off and unplug the washer. Close the water faucet. See the “Assistance or Service” section to contact a service representative.

F24

Possible Causes

- Too much laundry for a program/cycle with a small maximum load.

- Too much inlet water.

Solution

- Select and start the Rinse & Spin program to complete the interrupted wash program/cycle. Do not overload the washer. Follow the maximum load size indicated in the “Program/ Cycle Guide” section.

- Turn off the water faucet. Touch and hold the POWER button for at least 3 seconds to drain the water; wait until the drain phase has ended (“End” will appear on the display). Turn on the water faucet again. If water immediately flows into the washer without a program/cycle being started, an electrical component has failed. Close the water faucet, turn off and unplug the washer. See the “Assistance or Service” section to contact a service representative.

All other F.. failures

Possible Causes

- Failure of an electrical component.

Solution

- Touch and hold the POWER button for at least 3 seconds to reset the control. If the problem persists, turn off and unplug the washer. Close the water faucet. See the “Assistance or Service” section to contact a service representative.

Vibration or Off-Balance

Vibration, rocking, or “walking”

Possible Causes

- Feet may not be in contact with the floor and locked.

- Washer may not be level.

- Load could be unbalanced or too large

- The shipping bolts are still in the back of the washer.

Solution

- Front and rear feet must be in firm contact with floor, and washer must be level to operate properly. Jam nuts must be tight against the bottom of the cabinet.

- Check floor for flexing or sagging. If flooring is uneven, a 3/4" (19 mm) piece of plywood under your washer will reduce sound. Do not install washer on a raised wooden platform.

- Avoid tightly packing the load. Avoid washing single items. Balance a single item such as a rug or jeans jacket with a few extra items. Item or load not suitable for selected cycle. See “Cycle Guide” and “Using Your Washer.”

- See “Remove transport bolts from washer” in “Installation Instructions.”

Noises

Clicking or metallic noises

Possible Causes

- Door locking or unlocking.

- Objects caught in washer drain system

Solution

- The door will lock unlock and lock again. You will hear three clicks after touching and holding the Start/Pause button. This is normal.

- Empty pockets before washing. Loose items such as coins could fall between washer drum and tub or may block pump. It may be necessary to call for service to remove items. It is normal to hear metal items on clothing such as metal snaps, buckles, or zippers touch against the stainless steel drum.

Gurgling or humming

Possible Causes

- Washer may be draining water.

Solution

- The pump may make a humming sound with periodic gurgling or surging as final amounts of water are removed during the spin/drain cycles. This is normal at certain stages of the cycle.

Rolling or sloshing and occasional clicking (on low-speed spin)

Possible Causes

- Steel balls in the balancing system are balancing the load.

Solution

- This is normal at certain stages of the cycle.

Water Leaks

Check the following for proper installation

Possible Causes

- Fill hose not attached tightly

- Fill hose washer.

- Drain hose connection.

- Check household plumbing for leaks or clogged sink or drain.

- Strainer (or nylon stocking) on end of drain hose is clogged.

Solution

- Tighten fill-hose connection.

- Properly seat both fill-hose flat washers.

- Check that the drain hose is properly secured to drainpipe or laundry tub.

- Water can back up out of a clogged sink or drainpipe. Check all household plumbing for leaks (laundry tubs, drain pipe, water pipes, and faucet.)

- Remove strainer/stocking from drain hose.

Water or suds leaking from door or rear of cabinet

Possible Causes

- Not using HE detergent or using too much HE detergent.

- Residue on door glass.

Solution

- Only use HE detergent. Suds from regular detergents can cause leaking from the door or rear of cabinet. Always measure detergent and follow manufacturer’s directions based on your load requirements.

- Periodically clean the underside of the glass window to avoid potential leaks.

Leaking around door

Possible Causes

- Hair, lint, or other debris on inner door glass preventing proper seal with rubber door seal.

Solution

- Clean inner door glass and seal. See “Cleaning the Door Seal” in the “Washer Maintenance” section.

Washer not performing as expected

Load not completely covered in water

Possible Causes

- Water level not visible on door or does not cover clothes.

Solution

- This is normal for an HE front-load washer. The washer senses load sizes and adds the correct amount of water for optimal cleaning.

Washer won’t run or fill; washer stops working

Possible Causes

- Check for proper water supply

- Check proper electrical supply

- Normal washer operation.

- The washer door is not firmly shut.

- Washer not loaded as recommended.

- Not using HE detergent or using too much HE detergent.

- Door not opened between cycles.

Solution

- Hose must be attached and have water flowing to the inlet valve. Water faucet must be turned on. Check that inlet valve screen has not become clogged. Check for any kinks in inlet hose, which can restrict water flow.

- Plug power cord into a grounded 3 prong outlet. Do not use an extension cord. Ensure there is power to outlet. Do not plug into a GFI (Ground Fault Circuit Interrupter). Check electrical source or call an electrician to check if voltage is low. Reset a tripped circuit breaker. Replace any blown fuses.

- Door must be completely closed and latched for washer to run. Washer will pause during certain phases of cycle. Do not interrupt cycle. The washer pauses for about 2 minutes during certain cycles. Allow the cycle to continue. Some cycles feature periods of tumbling and soak. Washer may be stopped to reduce suds. Use only a proper amount of HE detergent. Cold Wash uses less water in the beginning of the cycle to provide a high concentration of detergent for optimal cleaning action. Following this concentrated tumbling, more water is used to complete the wash.

- The door must be closed during operation

- Remove several items, rearrange load evenly in washer drum. Close door and touch and hold the START/PAUSE button. Do not add more than one or two additional items after cycle has started to avoid tightly packing or unbalancing. Do not add more water to the washer.

- Only use HE detergent. Suds from regular detergents can slow or stop the washer. Always measure detergent, following manufacturer’s directions based on your load requirements. To remove suds, cancel cycle. Select Rinse & Spin. Touch the START/PAUSE button. Do not add more detergent.

- After any wash cycle is completed, the door must be opened and then closed before a new cycle can begin.

Washer stops during the program/cycle and the Start/Pause indicator blinks

Possible Causes

- It is the end of the program/cycle and Rinse Hold is activated.

- The program/cycle was interrupted (for example by the door being opened).

- The safety system has been activated. A failure indicator will light up and/or the display will show a failure code.

- Water faucet is closed

Solution

- Turn the knob to a spin speed, if desired; otherwise, rinse water will be drained and the program/cycle ended.

- Make sure the door is closed. Touch the START/PAUSE button to continue with the program/cycle.

- Refer to “Error Codes” at the beginning of “Troubleshooting.”

- Make sure the water faucet is open and that there are no kinks in the inlet hose.

Washer not draining/ spinning; loads are still wet

Possible Causes

- Drain hose extends into standpipe farther than 4.5" (114 mm).

- The drain hose is clogged, or the end of the drain hose is more than 49" (1.3 m) above the floor.

- Strainer/stocking on end of drain hose.

- The drain hose fits too tightly in the standpipe or is taped to the standpipe.

- Using cycles with a lower spin speed.

- Washer not loaded as recommended.

- The load may be out of balance.

- Not using HE detergent or using too much HE detergent.

- Small items may have been caught in the pump or stuck between the washer drum and the outer tub.

Solution

- Check drain hose for proper installation. Use drain hose form and securely attach to drainpipe or tub. Do not tape over drain opening.

- Lower drain hose if the end is higher than 49" (1.3 m) above the floor. Remove any clogs from drain hose. See “Installation Requirements” in “Installation Instructions.”

- Remove strainer/stocking from drain hose.

- The drain hose should be loose, yet fit securely. Do not seal the drain hose with tape. The hose needs an air gap. See “Route Drain Hose” in “Installation Instructions.”

- Cycles with lower spin speeds remove less water than cycles with high spin speeds. Use the recommended cycle/spin speed for your garment.

- A tightly packed or unbalanced load may not allow the washer to spin correctly, leaving the load wetter than normal. See “Cycle Guide” for load size recommendation for each cycle.

- Avoid washing single items. Balance a single item such as a rug or jeans jacket with a few extra items.

- Use only HE detergent. Suds from regular detergent or using too much detergent can slow or stop draining or spinning. Always measure and follow manufacturer’s directions for your load. To remove extra suds, select Rinse & Spin. Do not add detergent.

- Check the drum for any items sticking through the drum holes. Empty pockets and use garment bags when washing small items.

Washer vibrates during spinning

Possible Causes

- Transport bolts have not been removed.

- Washer is not level.

Solution

- Remove transport bolts (see “Installation Instructions”).

- Adjust leveling feet (see “Installation Instructions”). Make sure washer stands on a level and firm surface.

Spin speed “0” blinks on the control panel and/or laundry is still very wet

Possible Causes

- An unbalanced load prevented the Spin cycle to avoid damage to the washer.

Solution

- To spin wet laundry, add more laundry items of different sizes and start the Rinse & Spin program. Avoid small laundry loads consisting of a few large, absorbent items and wash different-sized items in one load.

Spin results are poor

Possible Causes

- Spin button was set to a low speed

- An unbalanced load prevented the Spin cycle.

- Excessive foam formation prevented spinning.

Solution

- Set a higher spin speed.

- See the solution for “Spin speed “0” blinks.”

- Start the Rinse & Spin” program. Avoid excessive amount of detergent; use the Dosing Aid option.

Door locked at end of wash cycle

Possible Causes

- Water remaining in washer after cycle.

- TumbleFresh™ option is on.

Solution

- Select Rinse & Spin to remove any water remaining in the washer. The washer door will unlock at the end of the drain.

- While this option is on, the load is tumbled periodically for up to 6 hours. The door remains locked during this time. To unlock the door, cancel the TumbleFresh™ option by touching the POWER button.

Door will not unlock

Possible Causes

- Water did not completely drain out of washer during the spin.

- Error code is displayed.

- Water temperature is hotter than 104°F (40°C).

Solution

- Select Rinse & Spin to remove any water remaining in the washer. The washer door will unlock at the end of the drain. It will take 1 minute for the door to unlock.

- Failure mode will lock the door. Touch the START/PAUSE button to exit; then wait for the door to unlock.

- Wait for the water temperature to drop.

Incorrect or wrong wash or rinse temperatures

Possible Causes

- Check for proper water supply

- Washing many loads.

Solution

- Hose must be attached to both washer and faucet, and have water flowing to inlet valve. Check that inlet valve screen is not clogged. Remove any kinks in hose.

- Your hot water tank may not have enough hot water to keep up with the number of hot or warm washes. This is normal.

Desired setting or option does not light

Possible Causes

- For best performance, not all settings are available with each cycle, and some options cannot be used together.

Solution

- See the “Program/Cycle Guide” for the available settings and options for each cycle.

Load not rinsed

Possible Causes

- Check for proper water supply

- Not using HE detergent or using too much HE detergent.

- Washer not loaded as recommended.

- The load may be out of balance

Solution

- Hose must be attached and have water flowing to the inlet valve. Water faucet must be on. Inlet valve screen on washer may be clogged. Remove any kinks in the inlet hose.

- The suds from non-HE detergent can cause the washer to operate incorrectly. Use only HE detergent. Always measure detergent and follow manufacturer’s directions based on load size and soil level.

- Avoid tightly packing the washer. The washer will not rinse well if tightly packed. Load with dry items only. See “Cycle Guide” for load size recommendations for each cycle. Use cycle designed for the fabrics being washed. Add only one or two garments after washer has started.

- When load unbalance occurs, a washing process will start to redistribute the load. This may lengthen the cycle time. Avoid washing single items. Balance a single item such as a rug or jeans jacket with a few extra items.

Load is wrinkled, twisted, or tangled

Possible Causes

- Washer not loaded as recommended.

- Spin speed too high for load.

- The washer is not unloaded promptly.

- Not choosing the right cycle for the load being washed.

- The wash water was not warm enough to relax wrinkles.

Solution

- Add load loosely. Items need to move freely reduce wrinkling and tangling. See “Cycle Guide” for load size recommendations for each cycle. Reduce tangling by mixing types of load items. Use the recommended cycle for the type of garments being washed.

- Select a lower spin speed. Note that items will be wetter than when using a higher spin speed.

- Unload the washer as soon as it stops or use the TumbleFresh™ option if you will not be able to unload the washer at the end of the cycle.

- Use the Delicates cycle or another cycle with a low spin speed to reduce wrinkling.

- If safe for load, use warm or hot wash water.

Not cleaning or removing stains

Possible Causes

- Washer not loaded as recommended.

- Not using HE detergent or using too much HE detergent.

- Hard water or high level of iron (rust) in water.

- Fabric softener dispensing ball used.

- Powdered detergent used for low-speed cycle.

- Not using correct cycle for fabric type.

- Not using dispensers.

- Not washing like colors together.

- Not enough detergent used, or hard water.

Solution

- Add load loosely. Items need to move freely for best cleaning. See “Cycle Guide” for load size recommendations for each cycle. Add only one or two garments after washer has started.

- Use only HE detergent. Always measure detergent and follow manufacturer’s directions based on load size and soil level.

- You may need to install a water softener and/or iron filter.

- Dispensing balls will not operate correctly with this washer. Add liquid fabric softener to the fabric softener compartment.

- Consider using liquid detergent.

- Use a warmer wash temperature to improve cleaning. If using Quick Wash cycle, wash only a few items. Use Heavy Duty cycle for tough cleaning. Add an extra rinse for heavily soiled loads.

- Use dispensers to avoid fabric softener staining. Load dispensers before starting a cycle. Avoid overfilling. Do not add products other than those specified directly to load.

- Wash like colors together and remove promptly after the cycle is complete to avoid dye transfer.

- Use more detergent for washing heavy soils in cold or hard water.

Odors

Possible Causes

- Monthly maintenance not done as recommended.

- Not using HE detergent or using too much HE detergent.

- Door not left open after use.

Solution

- Run the Clean Washer with affresh® cycle monthly or every 30 wash cycles. See “Washer Care” in “Washer Maintenance.” Unload washer as soon as cycle is complete. Use the TumbleFresh™ option if load cannot be removed immediately after the wash is complete.

- Use only HE detergent. Be sure to measure correctly. Always follow the manufacturer’s directions. See the “Using Your Washer” section.

- This washer has a tight seal to avoid water leaks. To avoid odors, leave the door open to allow the washer to dry between uses.

Fabric damage

Possible Causes

- Sharp items were in pockets during wash cycle.

- Strings and straps could have tangled.

- Items may have been damaged before washing.

- Fabric damage can occur if washer is tightly packed.

- Fabric damage can occur if washer door is closed on an item, trapping it between the door glass and the rubber seal.

Solution

- Empty pockets, zip zippers, and snap or hook fasteners before washing to avoid snags and tears.

- Tie all strings and straps before starting wash load.

- Mend rips and broken threads in seams before washing.

- Avoid tightly packing the washer. Load with dry items only. Use cycle designed for the fabrics being washed. Add only one or two garments after washer has started.

- Do not overfill the washer. Push wash load fully into the washer.

Gray whites, dingy colors

Possible Causes

- Load not sorted properly.

- Wash temperatures too low

- Not enough detergent used, or hard water.

Solution

- The transfer of dye can occur when mixing whites and colors in a load. Sort dark clothes from whites and lights.

- Use hot or warm temperatures if safe for the load. Make sure your hot water system is adequate to provide a hot water wash.

- Use more detergent for washing heavy soils in cold or hard water.

Incorrect dispenser operation

Possible Causes

- Clogged dispensers or laundry products dispensing too soon.

- Water in dispenser after cycle has finished

Solution

- Do not overfill dispenser. Overfilling causes immediate dispensing. Load dispensers before starting a cycle. Homes with low water pressure may result in residual powder in the dispenser. To avoid, select a warmer wash temperature if possible, depending on your load.

- It is normal for small amounts of water to remain in dispenser at the end of the cycle.

Detergent dispenser contains detergent residue after program ends

Possible Causes

- Inlet water pressure is too low; the mesh filter of the water supply hose may be blocked.

Solution

- Make sure the water faucet is properly opened. Check the mesh filters of the inlet hose and clean if necessary.

Single-dose laundry packet not dissolving

Possible Causes

- Adding laundry packet incorrectly

Solution

- Be sure laundry packet is added to washer drum before adding clothes. Do not add packet to dispenser. Follow the manufacturer’s instructions to avoid damage to your garments.

Cycle time changes or cycle time too long

Possible Causes

- Normal washer operation.

- Excessive suds in washer.

- Load may be out of balance

- Not using correct cycle for load type.

Solution

- The cycle times vary automatically based on your water pressure, water temperature, detergent, and clothes load. The options you select will also affect the cycle times.

- When excessive suds are detected, a special suds routine automatically starts to remove extra suds and ensure proper rinsing of your garments. This routine will add time to the original cycle.

- When load unbalance occurs, a washing process will start to redistribute the load. This extends the cycle time. Avoid washing single items. Balance a single item such as a rug or jeans jacket with a few extra items.

- The Quick Wash cycle is designed for smaller load sizes (2–4 items) of lightly soiled garments. If larger loads are washed in this cycle, cycle time will be increased. When using the Quick Wash or Delicates cycles, you should wash small loads. This ensures a gentle wash for your garments without increasing cycle times.

Liquid detergent on door glass prior to beginning of cycle

Possible Causes

- Detergent is free to flow from the single-dose dispenser.

Solution

- Do not add liquid detergent until laundry is loaded.

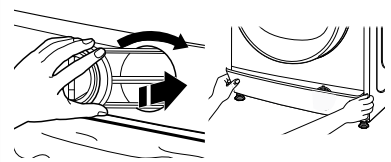

HOW TO OPEN DOOR IN CASE OF POWER FAILURE

Before opening the door as described below, refer to the failure “Door will not unlock” in the “Troubleshooting” section. The door may unlock by itself after the failure condition no longer exists; however, if you want to take out your laundry immediately, first try to unlock the door as described in Error Code FdL or F29 in the “Troubleshooting” section. If the door still cannot be opened, perform the following:

Before Opening Door:

- Turn off and unplug the washer.

- Close the water faucet.

- Wait until the drum has stopped rotating – never open the door while the drum is in motion.

- Wait until water and laundry have cooled down when washing with high temperatures.

Always drain the water before opening the door either by:

- Touching and holding the Power button until “rES” appears on the display.

or

- Following the instructions in the “Cleaning the Drain Pump Filter/Draining Residual Water” section.

To Open Door:

- Remove the screw.

- Pull down on the strap marked “Door open.” The door can now be opened and the laundry removed.

- After removing laundry, replace the strap by firmly turning the screw.

- Reinstall the base panel.

See other models: WFW90HEFC WTW8500DC CHW9160GW WTW8700EC WFW92HEFU