Documents: Go to download!

- Owner's manual - (English, French)

Owner’s Manual Refrigerator

Operating Instructions

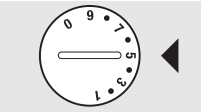

About the temperature control dial

Turning the dial to 0 stops cooling in both compartments—fresh food and freezer. It does not shut off power to the refrigerator.

Temperature Control Dial (on some models)

- The temperature control dial has nine settings plus 0. 1 is the warmest. 9 is the coldest. At first, set the dial at 5.

- After using the refrigerator, adjust the dial if necessary.

- Insert a coin into the slot in the middle of the dial and you can turn the dial to the setting that is best suited to your needs. Allow 24 hours for the refrigerator to get cold.

About the fresh food compartment shelves.

Shelf supports at various levels allow you to custom-space your shelves. Not all features are on all models.

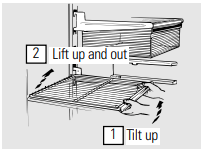

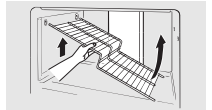

Half-Width Shelves

- One end of the shelf rests on a molded sidewall support; a bracket on the other end hooks into a track on the rear cabinet wall.

- To remove, lift the shelf up at front, then off the support and out of the track.

- To replace, select desired shelf height. With shelf front raised slightly, hook the bracket’s top lug into the track, then lower the shelf onto the support.

- NOTE: The shelf to the right of the track is designed to hook into the right-hand slot; the shelf to the left is designed to hook into the left-hand slot.

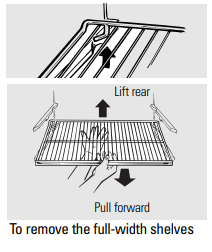

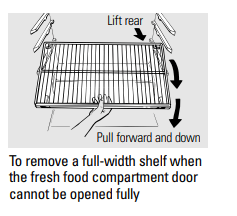

Full-Width Shelves

- Some models have a steel wire sliding shelf, a stationary tempered glass shelf, a spillproof shelf or two steel wire stationary shelves. These shelves can be moved to another place in the fresh food compartment.

- The full-width sliding shelf has stop-locks. When placed correctly on the shelf supports, the shelf will stop before coming completely out of the refrigerator and will not tilt when you place food on it or remove food from it.

Spillproof Shelves (on some models)

- Spillproof shelves have special edges to help prevent spills from dripping to lower shelves. To remove or replace the shelves, see the above instructions

About the freezer compartment shelves

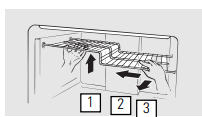

Step Shelf

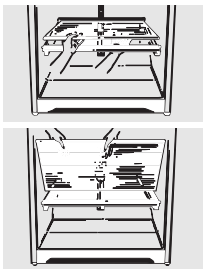

To remove the step shelf:

- Lift left side of shelf slightly.

- Move shelf to the left to free its right ends from holes in the cabinet wall.

- Lower right side of shelf, move shelf to the right and take it out.

To replace the step shelf:

- With shelf tilted as shown, fit left ends of shelf into holes in cabinet wall.

- Lift left side of shelf slightly, swing shelf up, fit right ends of shelf into holes in cabinet wall, and lower shelf into place.

About the storage drawers.

Not all features are on all models.

Fruit and Vegetable Drawers: Excess water that may accumulate in the bottom of the drawers should be emptied and the drawers wiped dry.

Fruit and Vegetable Drawers: Excess water that may accumulate in the bottom of the drawers should be emptied and the drawers wiped dry. Snacks Drawer: The snacks drawer can be moved to the most useful location for your family’s needs.

Snacks Drawer: The snacks drawer can be moved to the most useful location for your family’s needs.

About storage drawer and cover removal.

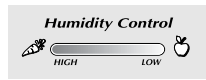

Adjustable Humidity Drawer (on some models)

- Slide the control all the way to the HIGH setting to provide high humidity recommended for most vegetables.

- Slide the control all the way to the LOW setting to provide lower humidity levels recommended for most fruits.

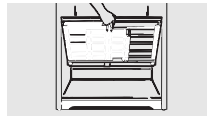

Drawer and Cover Removal

- Drawers can be removed easily by grasping the sides and lifting up slightly while pulling drawers past the stop location

Full-Width Drawer with Plastic Cover

- To remove the cover, lift it off its supports, pull it forward, tilt it and take it out.

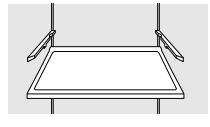

Twin Drawer Shelf

To remove:

- Remove the drawers.

- Reach in, push the front of glass cover up, and at the same time, pull it forward as far as it will come. Tilt it and take it out. Avoid cleaning the cold glass cover with hot water because the extreme temperature difference may cause it to break.

- Remove the drawer frame. (Always remove the glass cover before you take out the drawer frame.) Lift the frame off the supports at each side and back, pull it forward, tilt it and take it out.

To replace:

- Lower the frame until it rests on the supports at each side and back.

- Replace the glass cover, pushing its rear edge firmly into the rear frame channel and gently lowering the front into place.

- Replace the drawers.

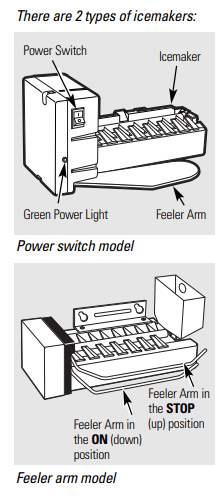

About the automatic icemaker.

A newly-installed refrigerator may take 12 to 24 hours to begin making ice.

Automatic Icemaker (on some models)

- The icemaker will produce approximately 100–130 cubes in a 24-hour period, depending on the freezer compartment temperature, room temperature, number of door openings and other use conditions.

- If the refrigerator is operated before the water connection is made to the icemaker, move the feeler arm to the STOP (up) position

- When the refrigerator has been connected to the water supply, move the feeler arm to the ON (down) position.

- The icemaker will fill with water when it cools to 15°F. A newly-installed refrigerator may take 12 to 24 hours to begin making ice cubes.

- Once the icemaker starts to make ice, it may take up to 48 hours to fill the bin, depending on the temperature settings and number of door openings.

- You will hear a buzzing sound each time the icemaker fills with water.

- Throw away the first few batches of ice to allow the water line to clear.

- Be sure nothing interferes with the sweep of the feeler arm.

- When the bin fills to the level of the feeler arm, the icemaker will stop producing ice.

- It is normal for several cubes to be joined together.

- If ice is not used frequently, old ice cubes will become cloudy, taste stale, shrink or fuse together.

- On power switch models, the green power light will blink if ice cubes get stuck in the icemaker. To correct this, set the power switch to O (off) and remove the cubes. Set the power switch to I (on) to restart the icemaker. After the icemaker has been turned on again, there will be a delay of about 45 minutes before the icemaker resumes operation.

- NOTE: In homes with lower-than-average water pressure, you may hear the icemaker cycle multiple times when making one batch of ice.

Icemaker Accessory Kit

- If your refrigerator did not already come equipped with an automatic icemaker, an icemaker accessory kit is available at extra cost.

- Check the back of the refrigerator for the specific icemaker kit needed for your model.

Care and cleaning of the refrigerator.

Cleaning the Outside

- The door handles and trim (on some models). Clean with a cloth dampened with soapy water. Dry with a soft cloth.

- Keep the outside clean. Wipe with a clean cloth lightly dampened with kitchen appliance wax or mild liquid dish detergent. Dry and polish with a clean, soft cloth.

- The stainless steel panels and door handles (on some models) can be cleaned with a commercially available stainless steel cleaner. Do not use appliance wax or polish on the stainless steel.

- Do not wipe the refrigerator with a soiled dish cloth or wet towel. These may leave a residue that can erode the paint. Do not use scouring pads, powdered cleaners, bleach or cleaners containing bleach because these products can scratch and weaken the paint finish.

Cleaning the Inside

- To help prevent odors, leave an open box of baking soda in the fresh food and freezer compartments.

- Unplug the refrigerator before cleaning. If this is not practical, wring excess moisture out of sponge or cloth when cleaning around switches, lights or controls.

- Use warm water and baking soda solution—about a tablespoon (15 ml) of baking soda to a quart (1 liter) of water. This both cleans and neutralizes odors. Rinse and wipe dry.

- After cleaning the door gaskets, apply a thin layer of petroleum jelly to the door gaskets at the hinge side. This helps keep the gaskets from sticking and bending out of shape.

- Avoid cleaning cold glass shelves (on some models) with hot water because the extreme temperature difference may cause them to break. Handle glass shelves carefully. Bumping tempered glass can cause it to shatter.

- Do not wash any plastic refrigerator parts in the dishwasher

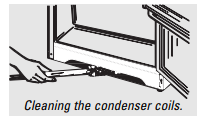

Condenser

- There is no need for routine condenser cleaning in normal home operating environments. However, in environments that may be particularly dusty or greasy, the condenser should be cleaned periodically for efficient refrigerator operation.

- To clean the condenser, turn the temperature control dial to 0. Sweep away or vacuum up dust.

- For best results, use a brush specially designed for this purpose. It is available at most appliance parts stores.

Moving the Refrigerator

- Be careful when moving the refrigerator away from the wall. All types of floor coverings can be damaged, particularly cushioned coverings and those with embossed surfaces.

- Turn the leveling legs at each front corner of the refrigerator counterclockwise until the rollers support the refrigerator. Pull the refrigerator straight out and return it to position by pushing it straight in. Moving the refrigerator in a side direction may result in damage to the floor covering or refrigerator.

- When pushing the refrigerator back, make sure you don’t roll over the power cord or icemaker supply line (on some models).

- After rolling the refrigerator back into place, turn the legs clockwise until the legs again bear the weight of the refrigerator.

Light Bulb Replacement

- To replace a burned-out bulb, unplug the refrigerator from its electrical outlet, unscrew the bulb when cool and replace it with an appliance bulb of the same or lower wattage.

- Turning the control to the 0 position does not remove power to the light circuit.

Preparing for Vacation

- For long vacations or absences, remove food and unplug the refrigerator. Move the temperature control dial to the 0 position, and clean the interior with a baking soda solution of one tablespoon (15 ml) of baking soda to one quart (1 liter) of water. Leave the doors open.

- Move the feeler arm to the STOP (up) position and shut off the water supply to the refrigerator.

- If the temperature can drop below freezing, have a qualified servicer drain the water supply system (on some models) to prevent serious property damage due to flooding.

Preparing to Move

- Secure all loose items such as grille, shelves and drawers by taping them securely in place to prevent damage. Be sure the refrigerator stays in an upright position during moving

Troubleshooting Tips

Normal operating sounds

Newer refrigerators sound different from older refrigerators. Modern refrigerators have more features and use newer technology.

Newer refrigerators sound different from older refrigerators. Modern refrigerators have more features and use newer technology.

Do you hear what I hear? These sounds are normal.

- The new high efficiency compressor may run faster and longer than your old refrigerator and you may hear a high-pitched hum or pulsating sound while it is operating.

- You may hear a whooshing sound when the doors close. This is due to pressure equalizing within the refrigerator

- You may hear the fans spinning at high speeds. This happens when the refrigerator is first plugged in, when the doors are opened frequently or when a large amount of food is added to the refrigerator or freezer compartments. The fans are helping to maintain the correct temperatures.

- You may hear cracking or popping sounds when the refrigerator is first plugged in. This happens as the refrigerator cools to the correct temperature.

- The compressor may cause a clicking or chirping sound when attempting to restart (this could take up to 5 minutes).

- Expansion and contraction of cooling coils during and after defrost can cause a cracking or popping sound.

- On models with an icemaker, after an icemaking cycle, you may hear the ice cubes dropping into the ice bucket.

- The flow of refrigerant through the freezer cooling coils may make a gurgling noise like boiling water.

- Water dropping on the defrost heater can cause a sizzling, popping or buzzing sound during the defrost cycle.

- A water dripping noise may occur during the defrost cycle as ice melts from the evaporator and flows into the drain pan.

- Closing the door may cause a gurgling sound due to pressure equalization.

Before you call for service…

Troubleshooting Tips Save time and money! Review the charts on the following pages first and you may not need to call for service.

Troubleshooting Tips Save time and money! Review the charts on the following pages first and you may not need to call for service.

| Problem | Possible Causes | What To Do |

| Refrigerator does not operate |

Refrigerator in defrost cycle Temperature control dial In 0 position Refrigerator is unplugged The fuse is blown/circuit breaker is tripped. |

Wait about 30 minutes for defrost cycle to end. Move the temperature control dial to a temperature in 0 position. setting.. Push the plug completely into the outlet. Replace fuse or reset the breaker. |

| Vibration or rattling (slight vibration is normal) | Roller screws or leveling legs need adjusting. | See Rollers and Leveling Legs. |

| Fresh food or freezer compartment too warm |

Temperature control dial not set cold enough Warm weather or frequent door openings. Door left open. Package blocking air duct in freezer compartment. |

See Rollers and Leveling Legs. See About the temperature control dial Set the temperature control dial one step colder. See About the temperature control dial. Check to see if package is holding door open. Check to see if package is blocking air duct in freezer compartment |

| Motor operates for long periods or cycles on and off frequently. (Modern refrigerators with more storage space and a larger space and a larger freezer require more operating time. They start and stop often to maintain even temperatures.) |

Normal when refrigerator is first plugged in. Often occurs when large amounts of food are placed in refrigerator Door left open Hot weather or frequent door openings. Temperature control dial set at the coldest setting Grille and condenser need cleaning. |

Wait 24 hours for the refrigerator to completely cool down. This is normal. Check to see if package is holding door open. This is normal See About the temperature control dial. See Care and cleaning |

| Frost or ice crystals on frozen food (frost within package is normal) |

Door left open. Too frequent or too long door openings. |

Check to see if package is holding door open. |

| Automatic icemaker does not work (on some models) |

Icemaker is not on Water supply turned off or not connected. Freezer compartment too warm. Piled up cubes in the storage bin cause the icemaker to shut off. |

Move the feeler arm to the ON (down) position. See Installing the water line. Wait 24 hours for the refrigerator to completely cool down. Level cubes by hand. |

| Frequent “buzzing” sound | Icemaker is on but the water supply to the refrigerator has not been connected. | Move the feeler arm to the STOP (up) position. Keeping it on will damage the water valve. |

| Cubes too small | Water shutoff valve connecting refrigerator to water line may be clogged. | Call the plumber to clear the valve. |

| Slow ice cube freezing |

Door left open Temperature control dial not set cold enough. |

Check to see if package is holding door open See About the temperature control dial. |

| Ice cubes have odor/taste |

Ice storage bin needs cleaning Food transmitting odor/taste to ice cubes Interior of refrigerator needs cleaning. |

Empty and wash bin. Discard old cubes. Wrap foods well. See Care and cleaning |

| Moisture forms on cabinet surface between the doors | Not unusual during periods of high humidity | Wipe surface dry and reset temperature control dial one setting colder. |

| Moisture collects inside (in humid weather, air carries moisture into refrigerator when doors are opened) | Too frequent or too long door openings. | |

| Refrigerator has odor |

Foods transmitting odor to refrigerator. Interior needs cleaning |

Foods with strong odors should be tightly wrapped. Keep an open box of baking soda in the refrigerator; replace every three months. See Care and cleaning |

See other models: GFE29HSDCSS JB480DM1BB PEB7227SL1SS JP5030DJ2BB GTS17JBWHRWW