Loading ...

Loading ...

Loading ...

LP Tank Exchange

•Many retailers that sell grillsoffer you the option of replacing

your empty LP tank through an exchange service. Use only

those reputable exchange companies that inspect, precision

fill, test and certify their cylinders. Exchange your tank only

for an OPD safety feature-equipped tank as described in

the "LP Tank" section of this manual.

•Always keep new andexchanged LP tanks in upright position

during use, transit or storage.

,Leak test new and exchanged LP tanks BEFORE

connecting to grill.

LP Tank Leak Test

Foryoursafety

•Leak test must be repeatedeach time LP tank isexchanged

or refilled.

•Do not smoke during leak test.

•Do not use anopen flame to checkfor gas leaks.

•Grill mustbe leak tested outdoors in a well-ventilated area,

away from ignition sources such as gas fired or electrical

appliances. During leak test, keep grill away from open

flames or sparks.

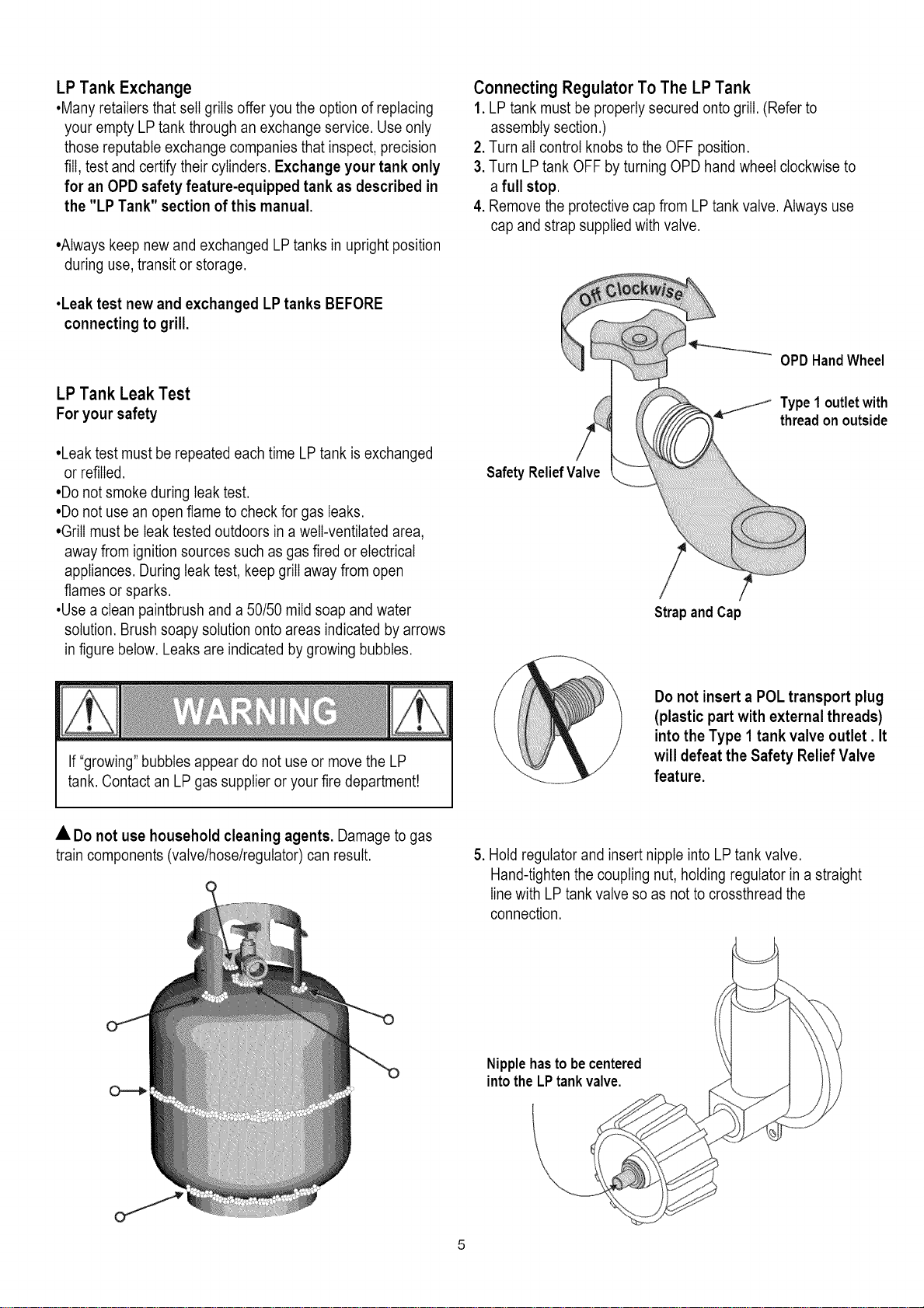

•Usea clean paintbrush and a 50/50 mild soap and water

solution. Brushsoapy solution onto areas indicated by arrows

infigure below. Leaks are indicated by growing bubbles.

Connecting Regulator To The LP Tank

1. LP tank must be properly secured onto grill. (Refer to

assembly section.)

2.Turn all control knobs to the OFF position.

3.Turn LP tank OFF by turning OPDhand wheel clockwise to

a full stop.

4. Remove the protective cap from LP tank valve. Always use

cap and strap suppliedwith valve.

OPDHandWheel

._ Type1 outletwith

threadon outside

SafetyReliefValve

/

Strapand Cap

If "growing" bubbles appear do not use or move the LP

tank. Contact an LP gas supplier or your fire department!

Do not insert a POL transport plug

(plastic part with external threads)

into the Type 1 tank valve outlet. It

will defeat the Safety Relief Valve

feature.

• Do not use household cleaning agents. Damage to gas

train components (valve/hose/regulator) can result. 5. Hold regulator and insert nipple into LP tank valve.

Hand-tightenthe coupling nut, holding regulator in a straight

linewith LP tank valve so as not to crossthread the

connection.

Nipplehasto be centered

into the LPtank valve.

Loading ...

Loading ...

Loading ...