Loading ...

Loading ...

Loading ...

Electric wiring requirements

The cooker MUST be installed in compliance with:

• Wiring connections in AS/NZS3000 Wiring Rules.

• Local regulations, municipal building codes and other

statutory regulations.

• Data Plate – Gives information about the rating and

is located behind the bottom of the oven door.

• A functional switch MUST be provided near the appliance in

an accessible position (AS/NZS3000 – Clause 4.7.1).

• Wiring MUST be protected against mechanical failure (AS/

NZS3000 – Clause 3.9).

• Disconnection from the fixed wiring must occur as required by

AS3000 wiring rules.

• This range must be connected with cable of 75°C rating

minimum.

• This product has passed the insulation resistance test after

manufacture. If the resistance reading is low at installation,

it is probably caused by moisture from the atmosphere

being absorbed by the elements after the range has been

produced. (pass at 0.01MΩ AS/NZS 3000 Wiring Rules

Clause 8.3.6.2).

• The cooker MUST be properly earthed.

• When connections are made to a multiphase 230/240V

supply, the bridge piece MUST be removed from between

the active connections.

• If the supply cord is damaged, it must be replaced by

the manufacturer, its service agent or similarly qualified

persons in order to avoid a hazard.

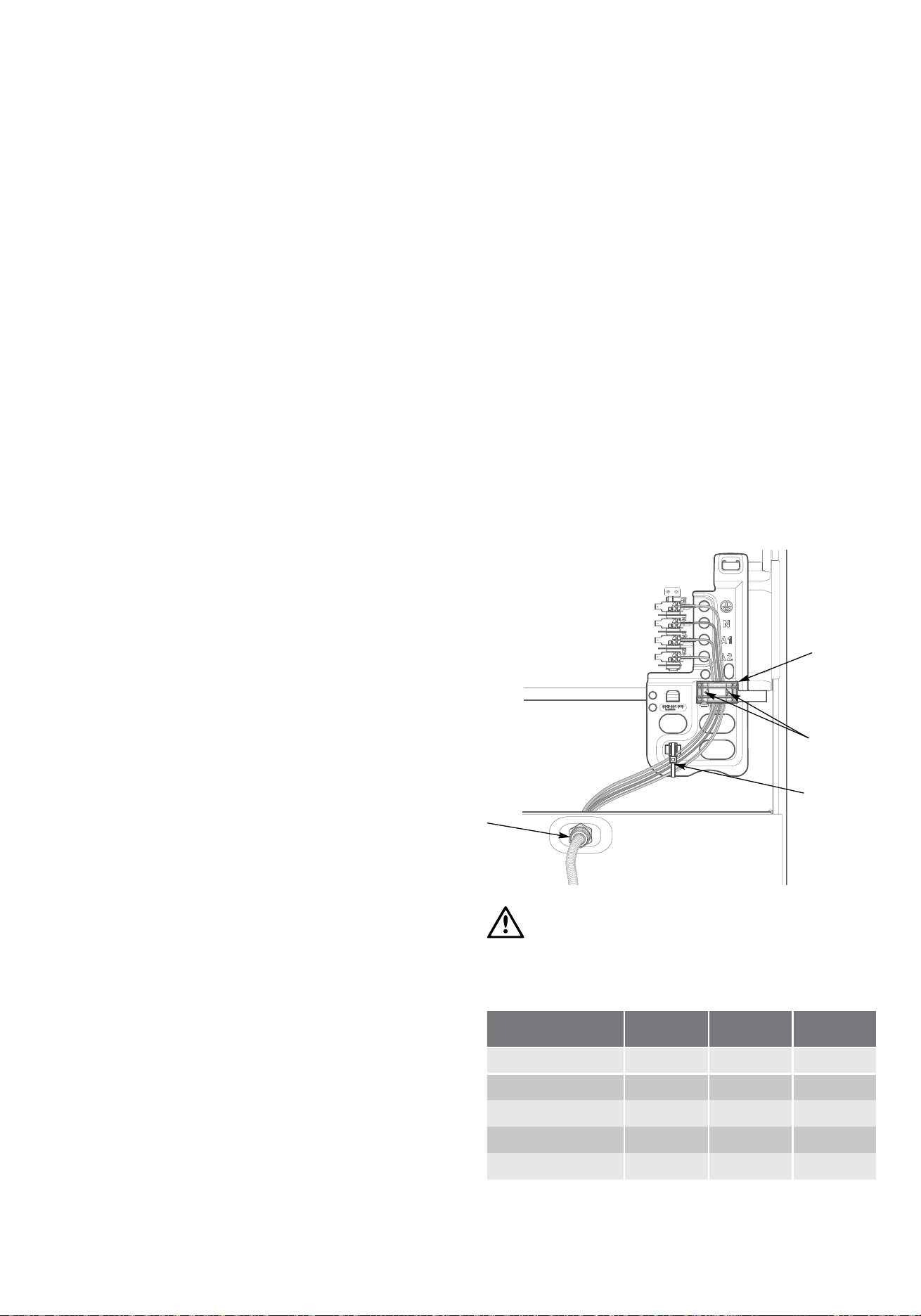

Hard wiring

1. Remove rear panel.

2. Fit wires through hole at bottom centre using the appropriate

gland to protect insulation of wires from the hole edge. Note

that the secondary insulation of the wires will probably need

to be removed to fit through gland. If the conduit to appliance

is required to bend due to rear wall an elbow may be

required to achieve this.

3. Set the length of wiring from the gland to terminal block,

ensuring length is sufficient but not excessive.

4. Make connections to terminals and engage wires into plastic

clip. Cable tie as per diagram and secure plastic clip with

two long screws supplied.

5. Replace rear cover.

WARNING

warning

Ensure wires cannot contact hot element ends or sharp edges.

Rated power input

Model Total kW A1 kW A2 kW

CFE532 8.2 2.2 6.0

CFE535 9.64 3.64 6.0

CFE536 8.2 2.24 6.0

CFE537 10.04 4.04 6.0

CFE547 9.64 4.04 5.6

installation

Restraining Device

Anchor Points

Connection

Gas

Point

150mm

650mm

Grill shutter

The following table shows the supply and operating pressures for various supplies.

Gas type Natural gas Universal LPG Propane

Supply pressure at inlet to appliance regulator

(if fitted)

1.13 (kPa)

Minimum

2.75* (kPa) 2.75* (kPa)

Operating pressure at

appliance test point

1.00 (kPa) 2.75 (kPa) 2.75 (kPa)

* If the regulator is placed upstream of the cooker inlet, as is normal for cookers operating on LPG, then the supply pressure

and operating pressure are the same. The following table shows the injector sizes for each burner.

The following table shows the injector sizes for each burner.

Injector Natural gas Universal LPG Propane

Low heat burner 1.00 mm 0.55 mm 0.62 mm

Medium heat burner 1.35 mm 0.70 mm 0.82 mm

High heat burner 1.60 mm 0.90 mm 0.95 mm

Intense heat wok burner 1.75 mm 1.00 mm 1.00 mm

Grill – main injector 1.50 mm 0.82 mm 0.82 mm

Oven – main injector 1.60 mm 0.82 mm 0.95 mm

Oven – bypass screw 0.73 mm 0.45 mm 0.45 mm

Checking pipe size

To work out a suitable pipe size for connection use the information in this table.

Gas Consumption (MJ/h)

Model Natural gas Universal LPG Propane

CFG503 58.1 45.7 56.5

CFG504 47 36.7 47.5

CFG513 60.2 48.2 58.3

CFG516 37.3 30.2 -

CFG517 49.1 39.2 49.3

Operation on NG

• The appliance regulator MUST be orientated so that the

pressure nipple is accessible

• The arrow showing the direction of flow MUST be

pointed correctly

• The regulator has a ½” BSP internal thread at the inlet and outlet.

Gas requirements

This appliance must be installed by an authorised person, according to all codes and regulations of:

• AS/NZS 5601.1 (particular attention to clause 6.10.1 and figure 6.3 on page 97, and clause 6.10.1.11)

• Local gas fitting regulations, municipal building codes and other statutory regulations.

The cookers come in three gas types:

Natural gas, Propane and Universal LPG. If the cooker is required to use ULPG, a conversion kit can be obtained by

contacting the Customer Care Centre for details. Before installation, check that the cooker is suitable for the gas supply by looking

at the data plate behind the bottom of the oven door.

installation

Chef 540 Upright Cooker INSTALLATION 2120 INSTALLATION Chef 540 Upright Cooker

Plastic

Clip

Plastic

clip screw

securing

points

Cable tie

Gland

1/2”B SP

Internal Thread

NG Regulator

Pressure test point

Also use information about the length

of the run, number of elbows, tees and

bends, the available service pressure

and the supply requirements. AS/NZS

5601.1 will help you with this matter.

Loading ...

Loading ...

Loading ...