Loading ...

Loading ...

Loading ...

18

LEAK TEST AND VACUUM

ENGLISH

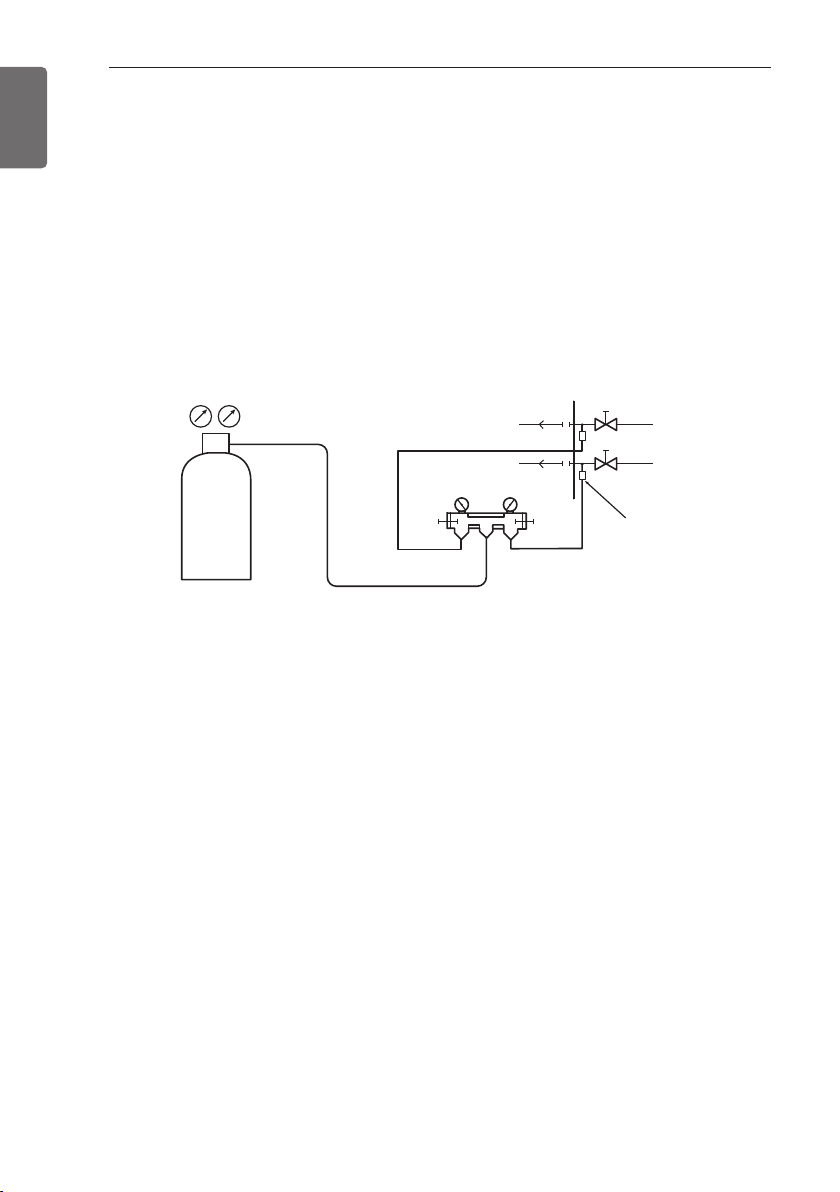

Leak tests are carried out to standards identical with the MULTI-V leak test.

Leak tests are carried out by pressurizing nitrogen gas to 3.8MPa (38.7 kgf/cm

2

). Refer to the

following picture for test methods.

(The service valve should be closed when carrying out tests and pressurizing liquid and gas

pipes.)

After nitrogen gas has been pressurized, pressure must not drop during a 24 hour period.

Low

pressure

High

pressure

Ⓐ

Ⓑ

Ⓕ

Ⓖ

Ⓙ

Ⓗ

Ⓘ

Ⓒ

ⒹⒺ

Ⓐ Nitrogen gas

Ⓑ Direction of indoor unit

Ⓒ Manifold gauge

Ⓓ Low-tension grip

Ⓔ High-tension grip

Ⓕ Service valve

Ⓖ Gas pipe

Ⓗ Liquid pipe

Ⓘ Outdoor unit

Ⓙ Service port

Vacuum testing is conducted to standards identical with the MULTI-V vacuum test.

As shown in the picture below, with the outdoor unit's service valve closed, use the vacuum

pump to perform vacuuming of the AHU and connector pipe from the stop valve's service port.

Vacuuming must always be conducted from the service port of liquid and gas pipes.

After maintaining a vacuum level of 5 Torr for one hour, there should be no change in the

vacuum level for another hour.

(If there is a change in the vacuum level, there could be a leak or moisture inside the pipe)

If there is a possibility of moisture inside the pipe, a vacuum must be maintained for 2 hours,

after which 0.05 Mpa (0.5 kgf/cm2) of nitrogen gas is injected.

After this, a vacuum is should be performed for at least one hour, maintained for an hour once 5

Torr is reached, and then the vacuum gauge is checked for changes.

※ Refrigerant should never be used for air purging.

※ Perform vacuuming using a vacuum pump with a vacuum gauge attached.

Vacuum

Leak test

LEAK TEST AND VACUUM

1,MFL70524401,영영 2018. 7. 23. 영영 5:04 Page 18

Loading ...

Loading ...

Loading ...