Loading ...

Loading ...

Loading ...

16

7c

9c

DISCARD PACKAGING

OPTIONALLY ATTACH BOTTLE HOLDER

(PURCHASED SEPERATELY) TO BEVERAGE CHILLER

GAS

ON

GAS

ON

1

2

Fibre washer

Floating nut

Elbow (½” BSP external thread)

Foam Tape

Adhesive side

20 mm

50 mm

+50 mm

NG

ALL Models

Make sure the connection point will be accessible with the cooktop installed.

To enable the gas supply to be readily shut o by the customer, make sure the connection

is tted with an isolating valve close to the cooktop.

Adjust to obtain a test point

pressure of 1 kPa with all the

burners operating at

highest setting.

Ensure the hose is long enough to allow for removal of cooktop for servicing.

Make sure the connector is located as shown in step 5 CLEARANCE DIMENSIONS.

The hose assembly must be AS/NZS 1869 Class B or D certied, with an Rp ½” (ISO 7‐1) female thread connection.

The hose assembly must be as short as practicable and comply with relevant AS 5601/NZS 5261 requirements.

The hose must not be kinked, subjected to abrasion or permanently deformed.

The hose must not be near or in contact with any hot surfaces

(e.g. base of metal hotlplate, ue, or chassis of underbench oven etc.)

If connecting the gas with a exible hose:

LPG

recessed to 50 mm

check all connections

Make sure the supply pressure

is regulated to 2.75 kPa, with

all the burners operating at

highest setting.

If converting to LPG, see 16 'Converting to a dierent gas type'

To check that the ignition system operates correctly, light each burner by itself, then all burners in combination.

Check for a well‐dened blue ame without any yellow tipping.

If any abnormality is evident, check that the components of the burner assembly are located properly

If proper operation cannot be obtained, contact your nearest F&P Authorised Service Centre.

The cooktop must not be used by the customer until proper operation has been achieved.

yellow tiplifting o

good ame

Arrow

Recycle responsibly

Model may vary from illustrations shown

Inspect the product(s) to verify that there is no shipping damage. If any damage is detected, call the

shipper and initiate a damage claim. DCS by Fisher & Paykel is not responsible for shipping damage.

NOTE: Do not discard any packing material until the unit has been inspected.

Examine the product to be sure there are no dents or scratches or discoloring.

each side

13/16” - 2 “

(20-51 mm)

each side

13/16” - 2 “

(20-51 mm)

8c

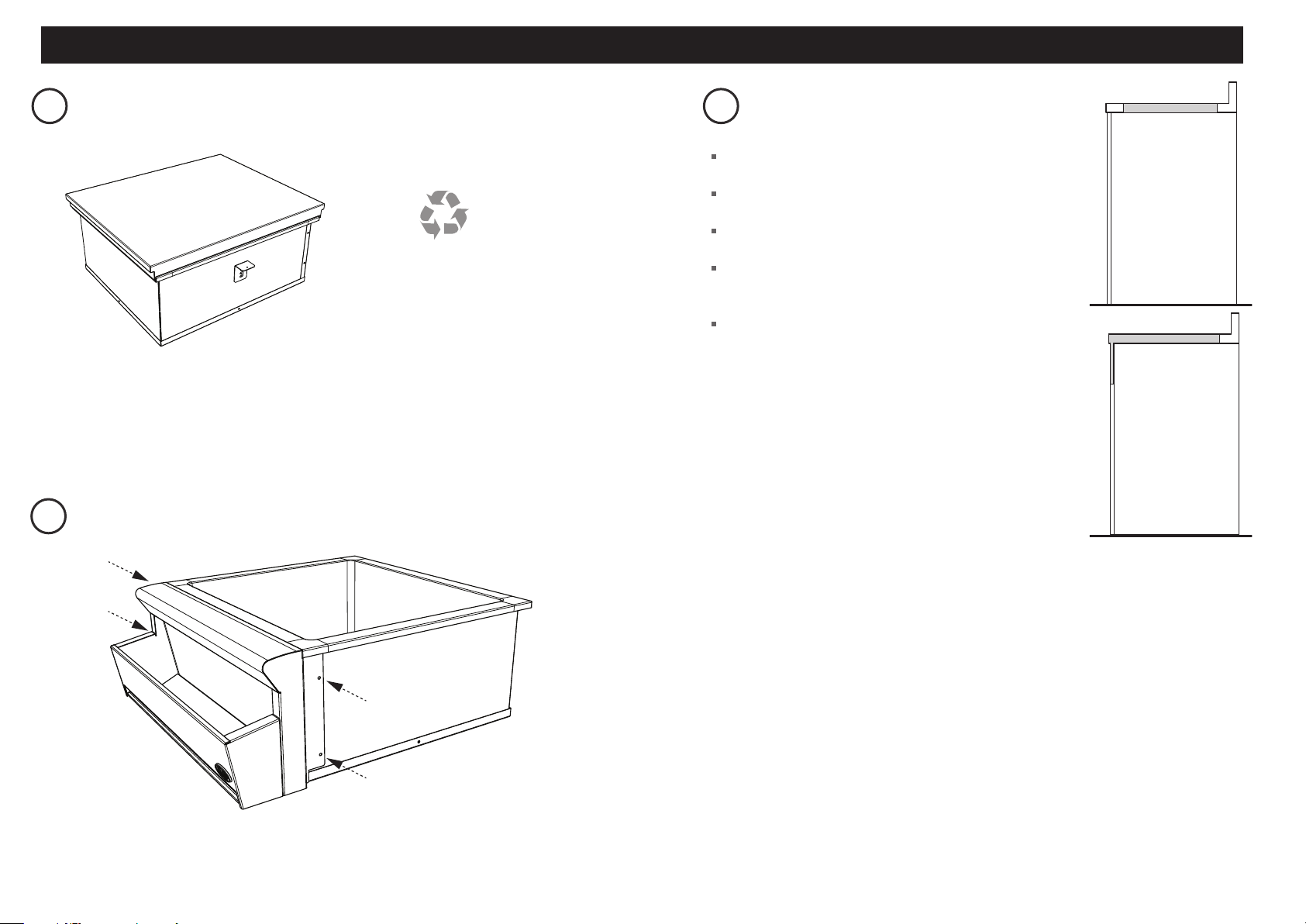

PREPARE THE CAVITY

Ensure the base of the cavity is level, square and able to

support the weight of the product when full.

Any cabinet and/or ground preparation must be completed

prior to installation.

All support structures must be constructed of materials

resistant to moisture damage.

Do no use harsh products (acid, solvent, sealers) around

this product.

For installation with the Bottle holder (purchased

separately), the cutout must extend to the front of the

cabintry, allowing space for the bottle holder (as shown).

CUTOUT WITHOUT

BOTTLE HOLDER

CUTOUT WITH

BOTTLE HOLDER

INSTALLING BEVERAGE CHILLER / BOTTLE HOLDER (PURCHASED SEPERATELY)

1

Fit the bottle holder onto the front of the Beverage chiller.

2

Attach the bottle holder to the Beverage chiller with the screws provided.

3

Unwrap the drip tray and fit in the bottom of the bottle holder.

Loading ...

Loading ...

Loading ...