Documents: Go to download!

User Manual

- User Manual - (English, Spanish)

- Warranty Guide - (English)

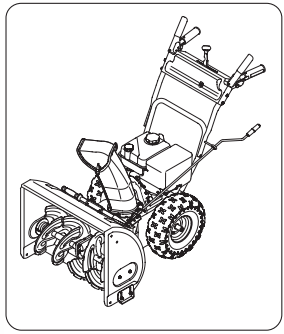

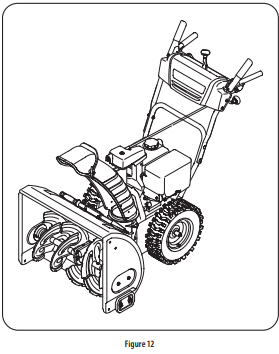

User Manual Snow Blower Craftsman CMXGBAM1054541

ASSEMBLY

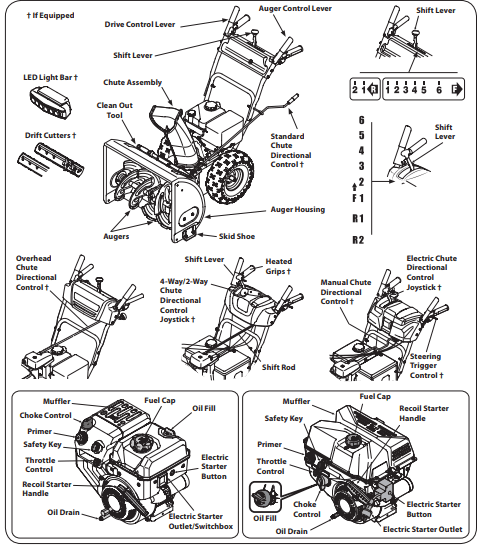

NOTE: This Operator’s Manual covers several models. Features may vary by model. Not all features in this manual are applicable to all models and the model depicted may differ from yours. Refer to Figure 1 which shows the different versions and match the contents of carton (chute and directional control rod/flex shaft) to identify your specific unit.

Figure 1

UNPACKING: Removing From Carton

- Cut the corners of the carton and lay the sides flat on the ground. Remove and discard all packing inserts.

- Move the snow blower out of the carton.

- Make certain the carton has been completely emptied before discarding it.

Handle Assembly

Refer to Figure 1 and proceed to your applicable chute style.

- Cut cable ties securing chute control rod or upper handle to the lower handle (if applicable), set aside the chute control rod (if applicable) and remove the wrap around the handles (if applicable).

NOTE: Do not cut the cable tie securing the cables to the engine for units equipped.

NOTE: On units with Overhead Chute Control, Four-Way Chute Control, and Electric Chute Control cut cable ties securing flex shaft to the lower handle and set the flex shaft aside. Remove rubber bands securing cables to carriage screws and cut cable tie securing shift rod to lower handle. Refer to Figure to help identify your unit.

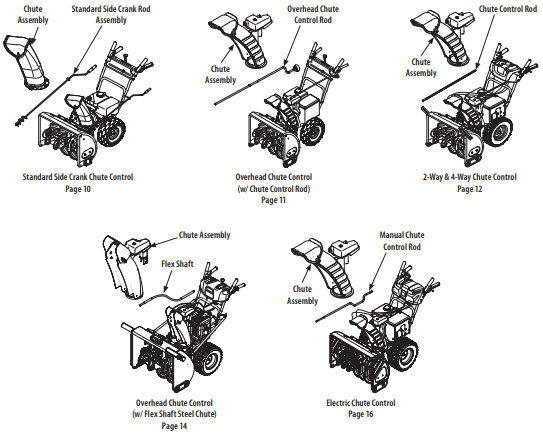

- Observe the lower rear area of the snow blower to be sure both cables are aligned with roller guides before pivoting the handle upward. See Figure 2.

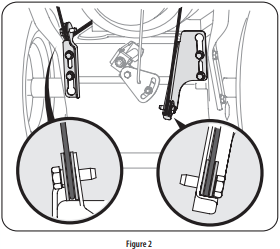

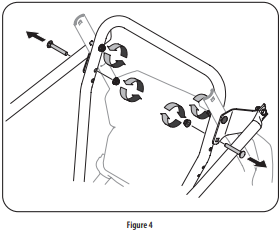

- Loosen the top two lock nuts securing the upper and lower handle and remove the two carriage screws from the lower handle and set aside. See Figure 3 or Figure 4 for units with side supports.

- Place shift lever in Forward-6 position or fastest forward speed (if equipped).

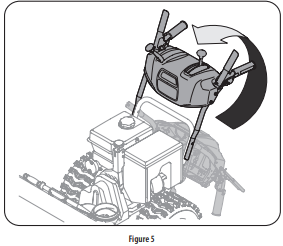

- Pull up and back on upper handle as shown in Figure 5. As you are raising the handle upward, make sure that both ends of the center cable are positioned properly in the brackets. Align upper handle with the lower handle.

NOTE: On select units with steel rod speed selectors, you may need to lower shift rod to the side slightly to maneuver handle panel over it when pivoting handle upward.

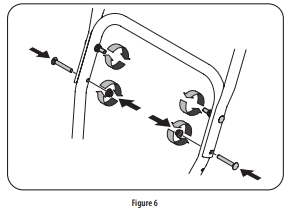

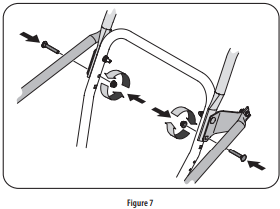

- Attach the two carriage screws and lock nuts removed in Step 2. Finish securing the handle by tightening the top two lock nuts loosened in Step 2. See Figure 6 or Figure 7 for units with side supports.

- Remove and discard any rubber bands, if present. They are for packaging purposes only.

- On units equipped with cable guides on top of the engine, check that all cables are properly routed through the cable guide. Then pull the cables towards the chute and pull the cable tie on the engine snug on the cables to secure in place.

NOTE: For smoothest operation, cables should all be to the left of the chute directional control rod.

Standard Side Crank Chute Control

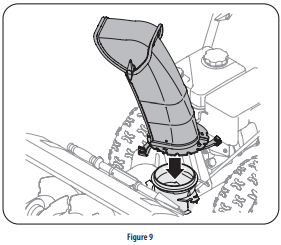

- Position chute assembly over base. See Figure 9.

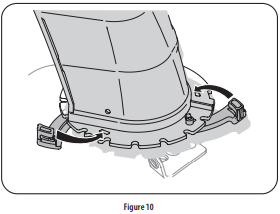

- Close flange keepers to secure chute assembly to chute base. Flange keepers will click into place when properly secure. See “Figure 10”10.

NOTE: Ensure the lower chute is secured to the flange on the chute base. The lower edge of the chute keeper should be positioned below the flange on the chute base after being clicked into place. If flange keepers will not easily click into place, use palm of your hand to apply swift, firm pressure to the back of each.

Chute Directional Control Assembly

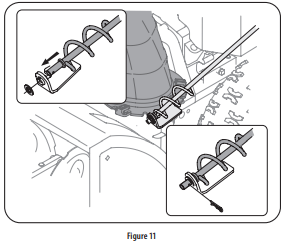

- Remove plastic cap (if present), flat washer and hairpin clip from end of chute directional control assembly. See Figure 11.

- Insert end of chute directional control assembly into lower bracket and secure chute directional control assembly with flat washer and hairpin clip removed in Step 1. If necessary, lower bracket can be adjusted. Refer to Chute Bracket Adjustment in Service section on page 32.

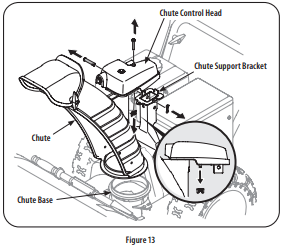

Overhead Chute Control (w/ Chute Control Rod)

- Remove wing nut and hex screw from chute control head and clevis pin and cotter pin from chute support bracket. Position chute assembly (forwardfacing) over chute base. See Figure 13.

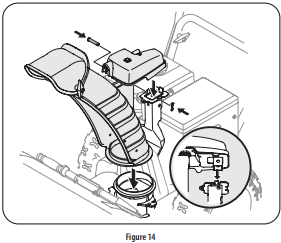

- Place chute assembly onto chute base and secure chute control head to chute support bracket with clevis pin and cotter pin removed in Step 1. See Figure 14.

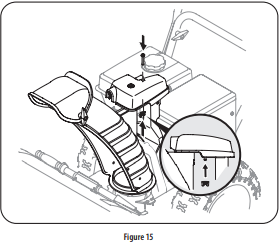

- Finish securing chute control head to chute support bracket with wing nut (a) and hex screw (b) removed in Step 1. See Figure 15.

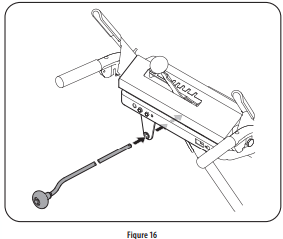

- Insert chute control rod into the support bracket on rear of the dash panel. See Figure 16.

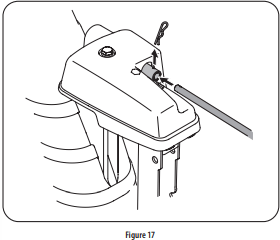

- Remove hairpin clip (a) from rear of chute control head. See Figure 17.

- Insert chute control rod (b) into rear of chute control head. See Figure 17. Secure chute control rod to chute control assembly with hairpin clip removed in Step 5.

Overhead Chute Control (w/ Flex Shaft & Steel Chute)

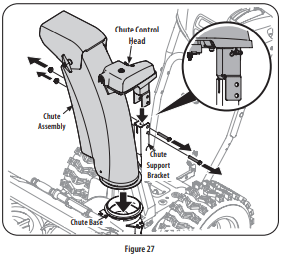

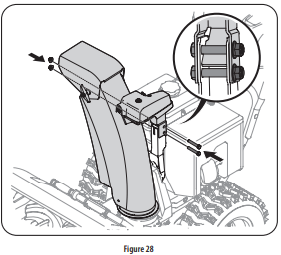

- Remove lock nuts and hex screws from chute support bracket (this will require two wrenches). See Figure 27.

- Place chute assembly onto chute base and chute control head onto chute support bracket. See Figure 27.

- Secure chute control head to chute support bracket with lock nuts and hex screws removed in Step 1. See Figure 28.

NOTE: For smoothest operation, the cables should all be to the left of the chute control rod.

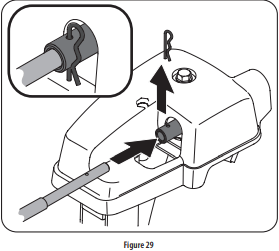

- Remove hairpin clip from rear of chute control assembly. See Figure 29.

- Insert flex shaft removed during handle assembly from lower handle into rear of chute directional control head. See Figure 29. Secure flex shaft to chute control head with hairpin clip removed in Step 4.

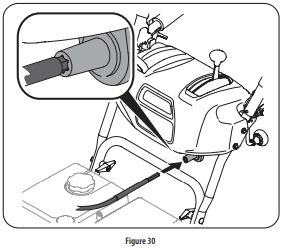

- Insert hex end of flex shaft into chute control rod coupling under dash panel. See Figure 30.

- Ensure speed selector is in fastest forward speed.

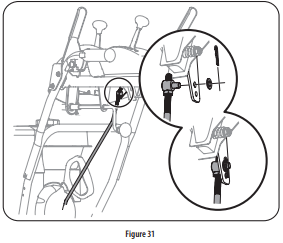

- Remove cotter pin and washer from ferrule on end of shift rod. See “Figure 31” inset.

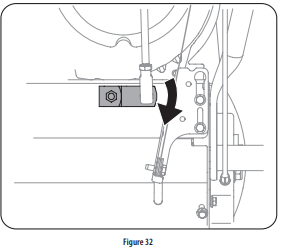

- Make sure the shift lever on the back of the transmission is rotated downward to the full extent of its rotation. See Figure 32.

- Insert ferrule into top hole of shift lever and secure with cotter pin (a) and washer (b) removed in Step 8. See Figure 31. Ferrule may need to be adjusted up or down.

Set-Up

Chute Control Cable Routing (If Equipped)

For units equipped with 2-way or 4-way chute control joystick, electric chute control and/or chute-pitch controls, ensure control cables are routed properly.

NOTE: For smoothest operation, cables should all be to the left of the chute directional control rod.

NOTE: The number of cables routed through the wire guides will depend on unit model.

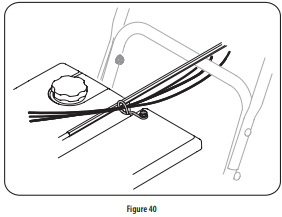

- Locate cable guide on top of engine and ensure cable(s) are properly routed through the cable guide. See Figure 40.

Shear Pins

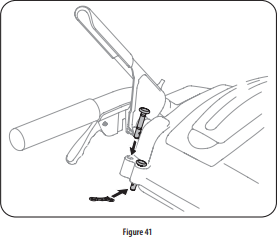

Holes are located in the plastic dash panel for convenient shear pin storage. See Figure 41. Refer to page 16 28 in the Operation section for more information regarding shear pin replacement.

NOTE: If the extra shear pins are not already assembled in the handle panel, they can be found in the manual bag.

Chute Clean-Out Tool

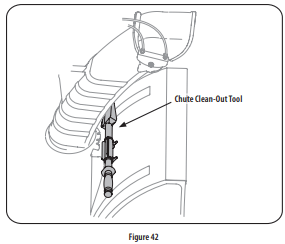

A chute clean-out tool is fastened to the top of the auger housing with a mounting clip. See Figure 42. The tool is designed to clear a chute assembly of ice and snow. This item is fastened with a cable tie at the factory. Cut the cable tie before operating the snow blower.

Drift Cutters (if equipped)

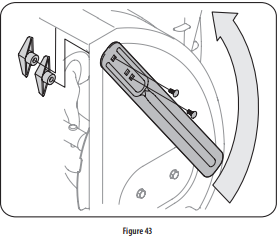

- Remove the two screws and wing knobs that secure each drift cutter, and remove them from the sides of the auger housing.

- Turn the drift cutters around and position them as shown in Figure 43 to the outside of the auger housing.

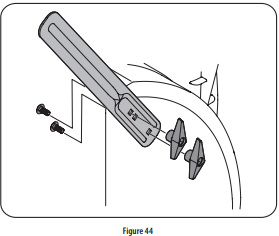

- Attach the drift cutters with the screws and wing knobs on the outside of the auger housing as shown in Figure 44.

Tire Pressure (If Applicable)

The tires are over-inflated for shipping purposes. Check the tire pressure before operating the snow blower. Refer to the tire side wall for tire manufacturer’s recommended psi and deflate (or inflate) the tires as necessary.

NOTE: Equal tire pressure is to be maintained at all times for performance purposes.

Adjustments

Skid Shoes

The snow blower skid shoes are adjusted at the factory to be approx 1/8” below the bottom surface of the shave plate. Adjust them downward, if desired, prior to operating the snow blower.

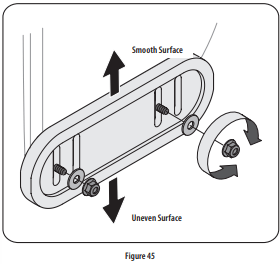

- For close snow removal on a smooth surface, raise skid shoes higher on the auger housing. Refer to Figure 45.

- Use a middle or lower position when the area to be cleared is uneven, such as a gravel driveway.

- NOTE: If you choose to operate the snow blower on a gravel surface, keep the skid shoes in position for maximum clearance between the ground and the shave plate.

To adjust the skid shoes:

- Loosen the four hex nuts (two on each side), flat washers, and carriage bolts. Move skid shoes to desired position. See Figure 45.

- Make certain the entire bottom surface of skid shoe is against the ground to avoid uneven wear on the skid shoes.

- Retighten nuts, washers, and bolts securely.

NOTE: The skid shoes on your unit may look slightly different (and have different hardware) than ones shown in Figure 45.

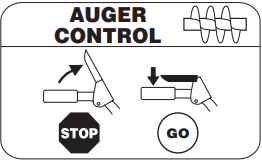

Auger Control

Check the adjustment of the auger control as follows:

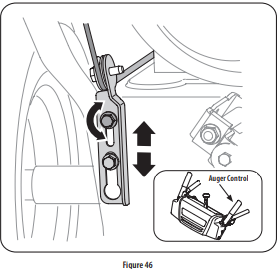

- The auger control is located on the left handle. See Figure 46 inset. When the auger control is released and in the disengaged “UP” position, the cable should have very little slack. It should NOT be tight.

- In a well-ventilated area, start the snow blower engine as instructed in Starting Engine on page 25-26 in the Operation section of this manual.

- While standing in the operator’s position (behind the snow blower), engage the auger.

- Allow the auger to remain engaged for approximately ten seconds before releasing the auger control. Repeat this several times.

- With the auger control in the disengaged “UP” position, walk to the front of the machine.

- Confirm that the auger has completely stopped rotating and shows NO signs of motion. If the auger shows ANY signs of rotating, immediately return to the operator’s position and shut OFF the engine. Wait for ALL moving parts to stop before adjusting the auger control.

- To readjust the control cable, loosen the upper hex bolt on the auger cable bracket. See Figure 46.

- Position the bracket upward to provide more slack (or downward to increase cable tension).

- Retighten the upper hex bolt.

- Repeat Step 2 through Step 6 above to verify proper adjustment has been achieved.

OPERATION

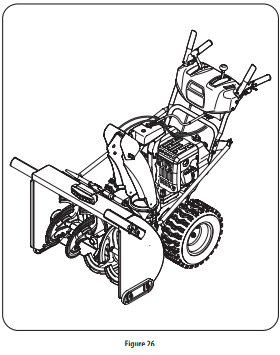

Now that you have set up your snow blower, it’s important to become acquainted with its controls and features. Refer to Figure 47.

NOTE: This Operator’s Manual covers several models. Snow blower features may vary by model. Not all features in this manual are applicable to all snow blower models and the snow blower depicted may differ from yours.

NOTE: All references to the left or right side of the snow blower are from the operator’s position. Any exceptions will be noted.

Shift Lever

- The shift lever is located on the right side of the handle panel. Place the shift lever into any of eight positions to control the direction of travel and ground speed.

Forward

- Your snow blower has six forward (F) speeds. Position one (1) is the slowest and position six (6) is the fastest.

Reverse

- Your snow blower has two reverse (R) speeds. Position one (1) is the slower and position two (2) is the faster.

Drift Cutters (If Equipped)

- The drift cutters are designed for use in deep snow. Their use is optional for normal snow conditions. Maneuver the snow blower so that the cutters penetrate a high standing snow drift to assist snow falling into the augers for throwing.

Safety Key

- The safety key is a safety device. It must be fully inserted in order for the engine to start. Remove the safety key when the snow blower is not in use.

- NOTE: Do not turn the safety key in an attempt to start the engine. Doing so may cause it to break.

Choke Control

- The choke control is found on the rear of the engine and is activated by turning the rotary choke knob to the CHOKE position. Activating the choke control closes the choke plate on the carburetor and aids in starting the engine.

Recoil Starter Handle

- This handle is used to manually start the engine.

LED Light (If Equipped)

- The LED light is located inside of the handle panel and is ON when the engine is running.

LED Light Bar (If Equipped)

- The LED headlight is located on top of the auger housing and is automatically turned ON when the engine is started.

Auger Control

The auger control is located on the left handle. Squeeze the control grip against the handle to engage the auger and start snow throwing action. Release to stop.

IMPORTANT: Refer to the Auger Control information in the Assembly & Set-Up section prior to operating your snow blower. Read and follow all instructions carefully and perform all adjustments to verify your snow blower is operating safely and properly

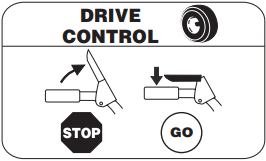

Drive Control/ Auger Control Lock*

- The drive control is located on the right handle. Squeeze the control grip against the handle to engage the wheel drive. Release to stop.

- *On select models, the drive control also locks the auger control so you can operate the chute directional control without interrupting the snow throwing process. If the auger control is engaged simultaneously with the drive control, the operator can release the auger control (on the left handle) and the augers will remain engaged. Release both controls to stop the augers and wheel drive.

- NOTE: Always release the drive control before changing speeds. Failure to do so will result in increased wear on your machine’s drive system.

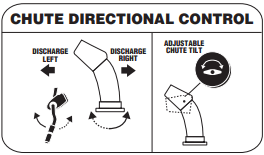

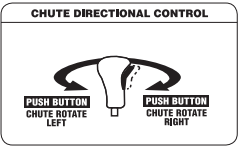

Overhead Chute Directional Control (If Equipped)

The overhead chute directional control is located in the center of the snow blower between the handle panel and lower handle. To change the direction in which snow is thrown, rotate the chute directional control.

Two-Way Chute Control (If Equipped)

The two-way chute control (Joystick) is located on the left side of the handle panel.

- To change the direction in which snow is thrown, squeeze the button on the chute control lever and pivot the chute control lever to the right or to the left.

Clean-Out Tool

The chute clean-out tool is conveniently fastened to the rear of the auger housing with a mounting clip. Should snow and ice become lodged in the chute assembly during operation, proceed as follows to safely clean the chute assembly and chute opening:

- Release both the Auger Control and the Drive Control.

- Stop the engine by removing the ignition key.

- Remove the clean-out tool from the clip which secures it to the rear of the auger housing.

- Use the shovel-shaped end of the clean-out tool to dislodge and scoop any snow and ice which has formed in and near the chute assembly.

- Refasten the clean-out tool to the mounting clip on the rear of the auger housing, reinsert the ignition key and start the snow blower’s engine.

- While standing in the operator’s position (behind the snow blower), engage the auger control for a few seconds to clear any remaining snow and ice from the chute assembly.

Before Starting Engine

Oil

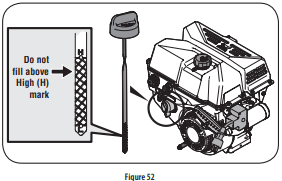

The unit was shipped with oil in the engine. Check oil level before each operation to ensure adequate oil in the engine.

NOTE: Be sure to check the engine on a level surface with the engine stopped.

- Remove the oil filler cap/dipstick and wipe the dipstick clean.

- Insert the cap/dipstick into the oil filler neck, but do NOT screw it in.

- Remove the oil filler cap/dipstick. If the level is low, slowly add oil (5W-30, with a minimum classification of SF/SG) until oil level registers between high (H) and low (L). NOTE: Do not overfill. Overfilling with oil may result in engine smoking, hard starting or spark plug fouling.

- Replace and tighten cap/dipstick firmly before starting engine.

Gasoline

Use automotive gasoline (unleaded or low leaded to minimize combustion chamber deposits) with a minimum of 87 octane. Gasoline with up to 10% ethanol or 15% MTBE (Methyl Tertiary Butyl Ether) can be used. Never use an oil/gasoline mixture or dirty gasoline. Avoid getting dirt, dust, or water in the fuel tank. DO NOT use E85 gasoline.

- Refuel in a well-ventilated area with the engine stopped. Do not smoke or allow flames or sparks in the area where the engine is refueled or where gasoline is stored.

- Do not overfill the fuel tank. After refueling, make sure the tank cap is closed properly and securely.

- Be careful not to spill fuel when refueling. Spilled fuel or fuel vapor may ignite. If any fuel is spilled, make sure the area is dry before starting the engine.

- Avoid repeated or prolonged contact with skin or breathing of vapor.

1. Clean around fuel fill before removing cap to fuel.

2. Fill tank until fuel reaches 1⁄2 inch below the bottom of the filler neck to allow space for fuel expansion. Be careful not to overfill.

Starting The Engine

NOTE: Allow the engine to warm up for a few minutes after starting. The engine will not develop full power until it reaches operating temperatures.

- Make certain both the auger control and drive control are in the disengaged (released) position.

- Insert key into slot. Make sure it snaps into place. Do not attempt to turn the key.

NOTE: The engine cannot start without the key fully inserted into the ignition switch.

Stopping The Engine

After you have finished snow-throwing, run engine for a few minutes before stopping to help dry off any moisture on the engine.

- Move throttle control to OFF position.

- Remove the key. Removing the key will reduce the possibility of unauthorized starting of the engine while equipment is not in use. Keep the key in a safe place. The engine cannot start without the key.

- Wipe any moisture away from the controls on the engine.

Using Snow Blower to Clear Snow

- Start the engine following starting instructions.

- Allow the engine to warm up for a few minutes as the engine will not develop full power until it reaches operating temperature.

- Rotate the chute assembly to the desired direction, away from bystanders and/or buildings.

- Making certain no bystanders or obstacles are in front of the unit, squeeze the auger control completely against the upper handle to fully engage the auger.

- While the auger control is engaged, squeeze the drive control completely against the upper handle to engage the wheels. Do not “feather” the drive control.

- As the snow blower starts to move, maintain a firm hold on the handle, and guide the snow blower along the path to be cleared.

- Release the auger and drive controls to stop the snow throwing action and forward motion. NOTE: Your unit is equipped with a clutch in the transmission. If the wheels stop turning while trying to discharge large volumes of snow, immediately disengage the drive control and allow the rotating auger to discharge snow from the housing. Reduce the clearing width and continue operation.

- On each succeeding pass, readjust the chute assembly to the desired position and slightly overlap the previously cleared path.

SERVICE AND MAINTENANCE

Engine Maintenance

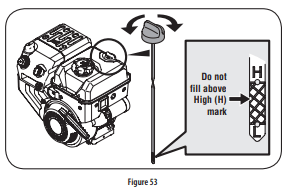

Checking Engine Oil

NOTE: Check the oil level before each use to be sure correct oil level is maintained.

NOTE: 208cc and 243cc engines use 600 ml (approx. 20 oz.).

NOTE: 277cc, 357 and 420cc engines use 1100 ml (approx. 37.2 oz).

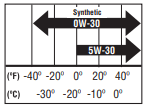

When adding oil to the engine, refer to viscosity chart below. Do not over-fill. Use a 4-stroke, or an equivalent high detergent, premium quality motor oil certified to meet or exceed U.S. automobile manufacturer’s requirements for service classification SG, SF. Motor oils classified SG, SF will show this designation on the container.

- Remove the oil filler cap/dipstick and wipe the dipstick clean.

- Insert the cap/dipstick into the oil filler neck, but do NOT screw it in.

- Remove the oil filler cap/dipstick. If level is low, slowly add oil until oil level registers between high (H) and low (L). See Figure 52 or Figure 53.

- Replace and tighten cap/dipstick firmly before starting engine.

Changing Engine Oil

NOTE: Change the engine oil after the first 5 hours of operation and once a season or every 50 hours thereafter.

- Drain fuel from tank by running engine until the fuel tank is empty. Be sure fuel fill cap is secure.

- Place suitable oil collection container under oil drain plug.

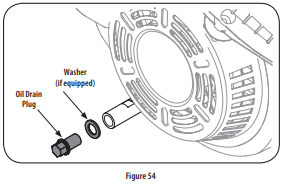

- Remove oil drain plug and washer (if equipped). See 54.

- Tip unit to drain oil into the container. Used oil must be disposed of at a proper collection center.

- Reinstall the drain plug and washer (if equipped) and tighten it securely.

- Refill with the recommended oil and check the oil level. See Recommended Oil Usage chart.

NOTE: 208cc and 243cc engines use 600 ml (approx. 20 oz.).

NOTE: 277cc, 357 and 420cc engines use 1100 ml (approx. 37.2 oz).

- Reinstall the oil filler cap/dipstick securely.

Checking Spark Plug

NOTE: Check the spark plug once a season or every 25 hours of operation. Change the spark plug once a season or every 100 hours. To ensure proper engine operation, the spark plug must be properly gapped and free of deposits.

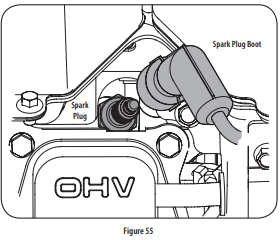

- Remove the spark plug boot and use a spark plug wrench to remove the plug. See Figure 55.

- Visually inspect the spark plug. Discard the spark plug if there is apparent wear, or if the insulator is cracked or chipped. Clean the spark plug with a wire brush if it is to be reused.

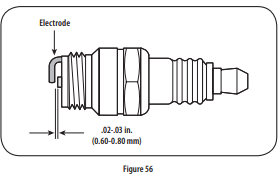

- Measure the plug gap with a feeler gauge. Correct as necessary by bending side electrode. See Figure 56. The gap should be set to .02-.03 inches (0.60- 0.80 mm).

- Check that the spark plug washer is in good condition and thread the spark plug in by hand to prevent cross-threading.

- After the spark plug is seated, tighten with a spark plug wrench to compress the washer.

NOTE: When installing a new spark plug, tighten 1⁄2-turn after the spark plug seats to compress the washer. When reinstalling a used spark plug, tighten 1⁄8- to 1⁄4-turn after the spark plug seats to compress the washer.

Shave Plate and Skid Shoes

The shave plate and skid shoes on the bottom of the snow blower are subject to wear. They should be checked periodically and replaced when necessary.

NOTE: The skid shoes on this machine have two wear edges. When one side wears out, they can be rotated 180° to use the other edge.

To remove skid shoes:

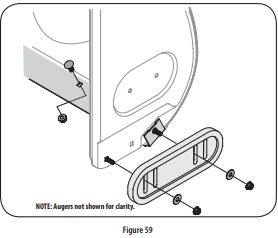

- Remove the two carriage bolts, washers, and hex flange nuts that secure each skid shoe to the snow blower.

- Reassemble new skid shoes with the four carriage bolts (two on each side), washers, and hex flange nuts. Refer to Figure 5959.

To remove shave plate:

- Remove the carriage bolts and hex nuts which attach it to the snow blower housing.

- Reassemble new shave plate, making sure heads of carriage bolts are to the inside of housing. Tighten securely. See Figure 59.

Drive Control

When the drive control is released and in the disengaged “up” position, the cable should have very little slack. It should NOT be tight. Also, if there is excessive slack in the drive cable or if the unit experiences intermittent drive while using, the cable may need to be adjusted. Check the adjustment of the drive control as follows:

- With the drive control released, push the snow blower gently forward. The unit should roll freely.

- Engage the drive control and gently attempt to push the snow blower forward. The wheels should not turn. The unit should not roll freely.

- With the drive control released, move the shift lever back and forth between the R2 position and the F6 position several times. There should be no resistance in the shift lever.

- If any of the above tests failed, the drive cable is in need of adjustment. Proceed as follows:

a. Shut off the engine as instructed in the Operation section.

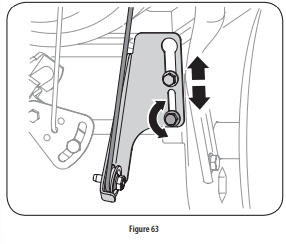

b. Loosen the lower hex bolt on the drive cable bracket. See Figure 63.

c. Position the bracket upward to provide more slack (or downward to increase cable tension).

d. Retighten the lower hex bolt.

Drive Belt

NOTE: Several components must be removed and special tools are required in order to replace the snow blower’s drive belt. Contact the nearest Sears Parts & Repair Center to have the drive belt replaced.

Friction Wheel Inspection (Steerable 500 and 800 Series & NonSteerable Single Speed 600 Series)

IIf the snow blower fails to drive with the drive control engaged, and performing the drive control cable adjustment fails to correct the problem, the friction wheel may need to be replaced. Follow the instructions below. Examine the friction wheel rubber for signs of wear or cracking and replace wheel if necessary.

- To prevent spillage, remove all fuel from tank by running engine until it stops.

- Place the shift lever in first Forward (F1) position.

- Carefully pivot the snow blower up and forward so that it rests on the auger housing.

- Remove the frame cover from the underside of the snow blower by removing the self-tapping screws which secure it.

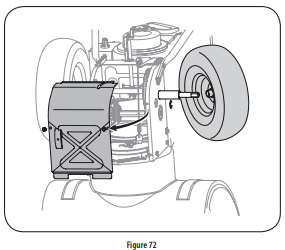

- Remove the right-hand wheel by removing the screw and bell washer which secure it to the axle. See Figure 72.

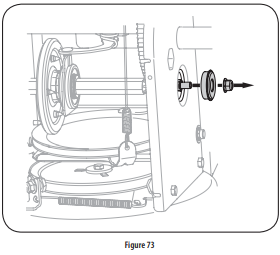

- Carefully remove the hex nut and washer which secures the hex shaft to the snow blower frame and lightly tap the shaft’s end to dislodge the ball bearing from the right side of the frame. See Figure 73. NOTE: Be careful not to damage the threads on the shaft.

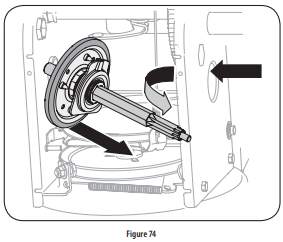

- Carefully position the hex shaft downward and to the left before carefully sliding the friction wheel assembly off the shaft. See Figure 74. NOTE: If you’re replacing the friction wheel assembly as a whole, discard the worn part and slide the new part onto the hex shaft.

- Follow the steps above in reverse order to reassemble components.

- Perform the test previously described in the Drive Control section.

If you’re disassembling the friction wheel and replacing only the rubber ring, proceed as follows:

NOTE: Not all friction whee

OFF-SEASON STORAGE

Preparing Engine

Engines stored over 30 days need to be drained of fuel to prevent deterioration and gum from forming in fuel system or on essential carburetor parts. If the gasoline in your engine deteriorates during storage, you may need to have the carburetor, and other fuel system components, serviced or replaced.

- Remove all fuel from tank by running engine until it stops. Do not attempt to pour fuel from the engine.

- Change the engine oil.

- Remove spark plug and pour approximately 1 oz. (30 ml) of clean engine oil into the cylinder. Pull the recoil starter several times to distribute the oil, and reinstall the spark plug.

- Clean debris from around engine, and under, around, and behind muffler. Apply a light film of oil on any areas that are susceptible to rust.

Store in a clean, dry and well ventilated area away from any appliance that operates with a flame or pilot light, such as a furnace, water heater, or clothes dryer. Avoid any area with a spark producing electric motor, or where power tools are operated.

Preparing Snow Blower

- When storing the snow blower in an unventilated or metal storage shed, care should be taken to rustproof the equipment. Using a light oil or silicone, coat the equipment, especially any chains, springs, bearings and cables.

- Remove all dirt from exterior of engine and equipment.

- Follow lubrication recommendations.

- Store equipment in a clean, dry area.

- Inflate the tires to the tire manufacturers recommended pressure. Refer to tire sidewall.

- Store snow blower in operating position with both wheels and shave plate on level ground surface.

TROUBLESHOOTING

Engine fails to start

1. Choke control not in CHOKE position.

Move choke control to CHOKE position.

2. Spark plug wire disconnected.

Connect wire to spark plug.

3. Faulty spark plug.

Clean, adjust gap, or replace.

4. Fuel tank empty or stale fuel.

Fill tank with clean, fresh gasoline.

5. Engine not primed.

Prime engine as instructed in the Operation section.

6. Safety key not inserted.

Insert safety key fully into the switch.

7. Extension cord not connected (when using electric start button, on models so equipped).

Connect one end of the extension cord to the electric starter outlet and the other end to a three-prong 120V, grounded, AC outlet.

Engine running erratically/ inconsistent RPM (hunting or surging)

1. Engine running on CHOKE.

Move choke control to RUN position.

2. Stale fuel.

Fill tank with clean, fresh gasoline.

3. Water or dirt in fuel system.

Drain fuel tank by running engine until it stops. Refill with fresh fuel

4. Carburetor out of adjustment.

Contact a Sears or other qualified service dealer for repair

5. Over-governed engine

Contact a Sears or other qualified service dealer for repair.

Excessive vibration

1. Loose parts or damaged auger or impeller

Stop engine immediately and disconnect spark plug wire. Tighten all bolts and nuts. If vibration continues, have unit serviced by a Sears Parts & Repair Center.

Loss of power

1. Spark plug wire loose.

Connect and tighten spark plug wire

2. Gas cap vent hole plugged.

Remove ice and snow from gas cap. Be certain vent hole is clear.

Unit fails to propel itself

1. Drive cable in need of adjustment.

Adjust drive control cable. Refer to Service and Maintenance section.

2. Drive belt loose or damaged.

Contact a Sears or other qualified service dealer for repair using identical replacement part.

3. Worn friction wheel.

Have friction wheel replaced by a Sears or other qualified service dealer using identical replacement part.

Unit fails to discharge snow

1. Chute assembly clogged.

Stop engine immediately and disconnect spark plug wire. Clean chute assembly and inside of auger housing with clean-out tool.

2. Foreign object lodged in auger.

Stop engine immediately and disconnect spark plug wire. Remove object from auger with clean-out tool.

3. Auger cable in need of adjustment.

Adjust auger control cable. Refer to Assembly section.

4. Auger belt loose or damaged.

Replace auger belt. Refer to Service and Maintenance section.

5. Shear pin(s) sheared.

Replace with new shear pin(s). Refer to Operation section.

Chute fails to easily rotate 180-200 degrees

1. Chute assembled incorrectly.

Disassemble chute control and reassemble as directed in the Assembly section.

Unit plows snow instead of blowing it

1. Low/slow ground speed in wet/slushy snow 1-3” deep.

Increase ground speed. Always operate engine at FULL throttle.

2. Shear pin(s) sheared.

Replace with new shear pin(s). Refer to Operation section

See other models: CMXGBAM1054544 CMXGBAM1054538 CMXGBAM1054545 CMXGBAM1054540 CMXGBAM1054539