Documents: Go to download!

- Owner's manual - (English)

- Operating Controls

- Basic Operation & Riding

- Servicing Your Honda

- Taking Care of the Unexpected

Table of contents

User manual

Operating Controls

Operation Component Locations

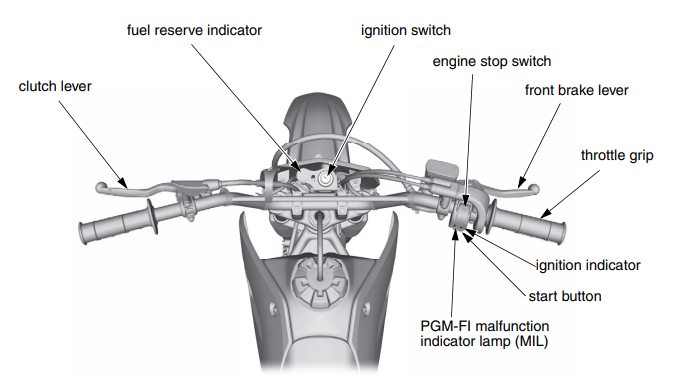

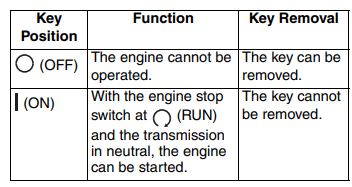

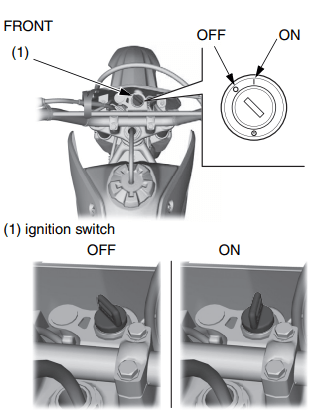

Ignition Switch

The ignition switch (1) is used to prevent unauthorized use of the motorcycle. Before riding, insert the key and turn it to the  (ON) position.

(ON) position.

After parking the motorcycle, remove the key.

Start Button

The start button is used for starting the engine. Pushing the button in starts the engine. See Starting Procedure. When the start button is pushed, the starter motor will crank the engine.

Engine Stop Switch

The engine stop switch can be used to turn the engine off in an emergency. To operate, turn the switch to the (STOP) position. The switch must be in the

(STOP) position. The switch must be in the (RUN) position to start the engine.

(RUN) position to start the engine.

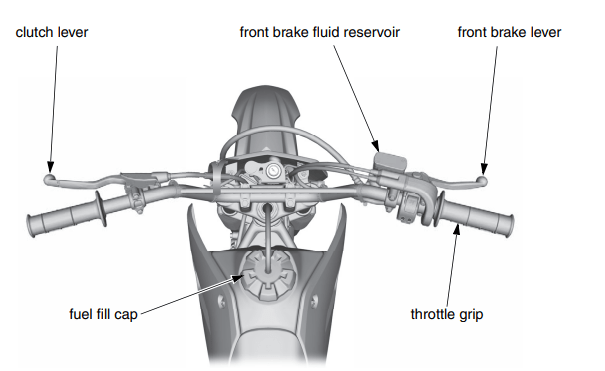

Front Brake Lever

The front brake lever is used to slow or stop your motorcycle. To operate, pull the lever. For information on braking techniques.

Throttle

The throttle controls engine rpm (speed). To increase engine rpm, rotate the grip toward you. To reduce engine rpm, rotate the grip away from you. The throttle will automatically return to the closed position (engine idle) when you remove your hand.

Clutch Lever

The clutch lever is used to disengage the clutch whenever you shift gears. To operate, pull the clutch lever in all the way before shifting, then slowly release it after shifting.

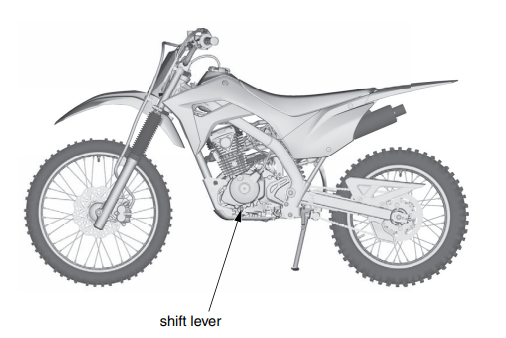

Shift Lever

The shift lever is used to select the next higher or lower gear in the transmission. To operate, raise the shift lever (after pulling in the clutch lever) to engage the next higher gear or depress the shift lever to engage the next lower gear. See Shifting Gears

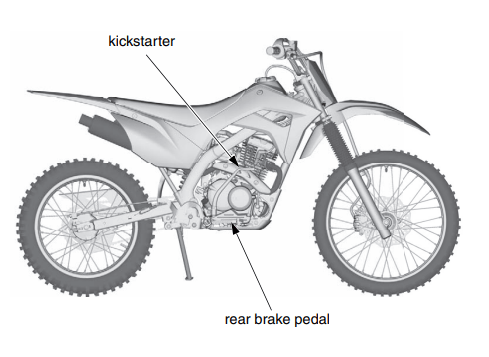

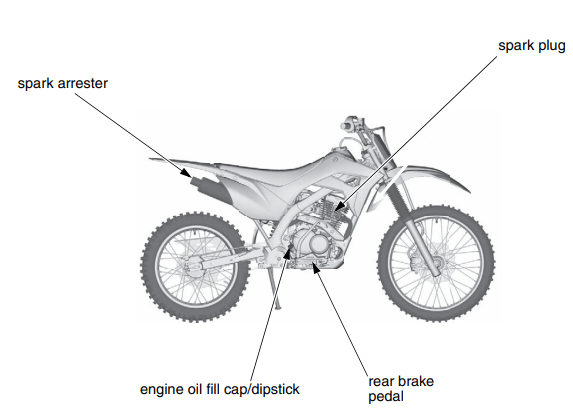

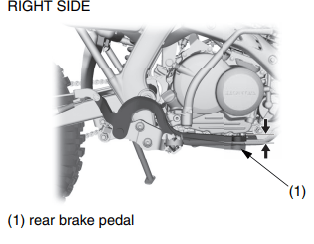

Rear Brake Pedal

The rear brake pedal is used to slow or stop your motorcycle. To operate, depress the pedal. For information on braking techniques.

Kickstarter

The kickstarter is used to start the engine. To operate, swing the kickstarter out from its stored position and depress it through its entire stroke. See Starting Procedure

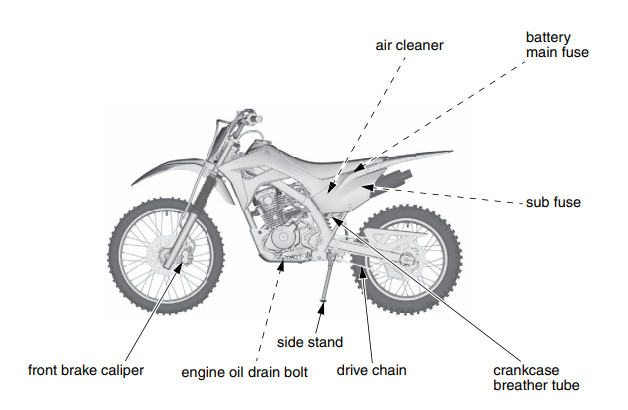

Side Stand

The side stand is used to support your motorcycle while parked . To operate, use your foot to lower the stand. Before riding, raise the stand.

PGM-FI Malfunction Indicator Lamp (MIL)

Lights when there is any abnormality in the PGM-FI (Programmed Fuel Injection) system. The indicator should also light for a few seconds and then go off when the ignition switch is turned to the (ON) position with the engine stop switch in the

(ON) position with the engine stop switch in the  (RUN) position. If the indicator does not come on when it should, have your dealer check for problems. If it comes on at any other time, reduce speed and take the motorcycle to your dealer as soon as possible.

(RUN) position. If the indicator does not come on when it should, have your dealer check for problems. If it comes on at any other time, reduce speed and take the motorcycle to your dealer as soon as possible.

Fuel Reserve Indicator

When this indicator comes on while riding, fuel reserved in the tank is about: 0.2 US gal (0.7 ) The indicator should also light for a few seconds and then go off when the ignition switch is turned to the (ON) position with the engine stop switch in the

(ON) position with the engine stop switch in the  (RUN) position. If the indicator does not come on when it should, have your dealer check for problems.

(RUN) position. If the indicator does not come on when it should, have your dealer check for problems.

Ignition indicator

When the ignition switch is turned on, the ignition indicator comes on. If the indicator does not come on when it should, have your dealer check for problems.

Basic Operation & Riding

Starting & Stopping the Engine

Starting Procedure

This motorcycle has a fuel-injected engine. Follow the procedure indicated below.

Any Air Temperature

1. Using the start button

With the throttle completely closed, press the start button.

Using the kickstarter

Lightly depress the kickstarter until resistance is felt.

Then let the kickstarter return to the top of its stroke.

With the throttle completely closed, operate the kickstarter starting from the top of the stroke, kick through to the bottom with a rapid, continuous motion.

NOTICE Allowing the kickstarter to snap back freely against the pedal stop can damage the engine case.

2. If you cannot start the engine, open the throttle slightly (about 0.1 in (3 mm), without freeplay)

How to Stop the Engine

To stop the engine, shift into neutral, and turn the ignition switch to the OFF position.

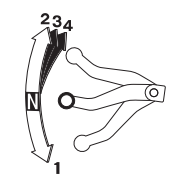

Shifting Gears

Your motorcycle has four forward gears.

To start riding, after the engine has been warmed and the side stand raised:

- Close the throttle and pull the front brake lever in.

- Pull the clutch lever all the way in.

- Depress the shift lever from neutral down to first gear.

- Release the front brake. Gradually open the throttle while you slowly release the clutch lever. If engine rpm (speed) is too low when you release the clutch lever, the engine will stall. If engine rpm is too high or you release the clutch lever too quickly, your motorcycle may lurch forward.

- When you attain a moderate speed, close the throttle, pull the clutch lever in, and raise the shift lever. After shifting, release the clutch lever and apply the throttle.

- To continue shifting up to each higher gear, repeat step 5.

- To shift down to a lower gear, close the throttle, pull the clutch lever in, and depress the shift lever. After shifting, release the clutch lever and apply the throttle.

Remember to close the throttle and pull the clutch lever in completely before shifting.

NOTICE Improper shifting may damage the engine, transmission, and drive train.

Learning when to shift gears comes with experience. Upshift to a higher gear or reduce throttle before engine rpm (speed) gets too high.

NOTICE Downshift to a lower gear before you feel the engine laboring (lugging) at low rpm. Downshifting can help slow your motorcycle, especially on downhills. However, downshifting when engine rpm is too high can cause engine damage.

To prevent transmission damage, do not coast or tow the motorcycle for long distances with the engine off.

Braking

To slow or stop, apply the front brake and rear brake smoothly, while downshifting to match your speed. Gradually increase braking as you feel the brakes slowing your speed. To prevent stalling the engine, pull the clutch lever in before coming to a complete stop. For support, put your left foot down first, then your right foot when you have finished using the rear brake.

For maximum braking, close the throttle and firmly apply the brake lever and pedal controls.

Applying the brakes too hard may cause the wheels to lock and slide, reducing control of your motorcycle. If this happens, release the brake controls, steer straight ahead until you regain control, then reapply the brakes more gently.

Generally, reduce your speed or complete braking before beginning a turn. Avoid braking or closing the throttle quickly while turning. Either action may cause one or both wheels to slip. Any wheel slip will reduce your control of your motorcycle.

When riding in wet or rainy conditions, or on loose surfaces, the ability to maneuver and stop will be reduced. All of your actions should be smooth under these conditions. Rapid acceleration, braking or turning may cause loss of control. For your safety, exercise extreme caution when braking, accelerating, or turning.

When descending a long, steep grade, use engine compression braking by downshifting, with intermittent use of both brakes.

When you brake to a stop, pull the clutch lever in before stopping completely to prevent stalling the engine. For support, put your left foot on the ground first, then your right foot when you have finished braking.

Parking

Lower the side stand to support your motorcycle. Turn the ignition switch OFF and remove the key. Always choose a level place to park.

Post-ride Inspection

When you return home after riding, thoroughly clean your motorcycle and remove any dirt, mud, brush, rocks or other objects you may have picked up along the way. After cleaning, carefully inspect your motorcycle for leaks or damage. Be sure to lubricate the drive chain to prevent rusting.

Servicing Your Honda

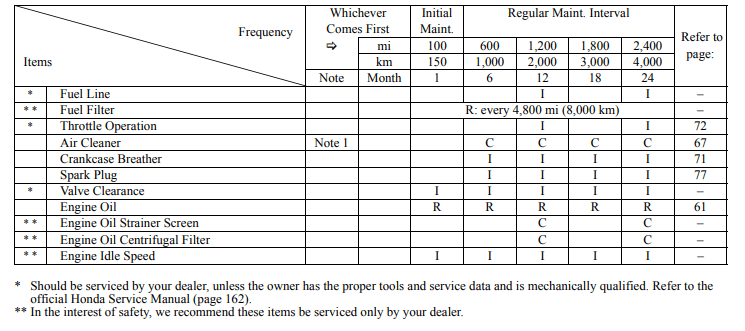

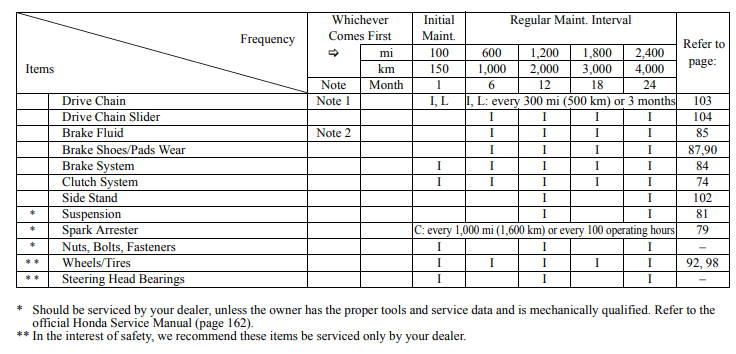

Maintenance Schedule

Because your motorcycle does not have an odometer, service intervals in the maintenance schedules are expressed in terms of riding days as well as miles. To avoid overlooking required service, we urge you to develop a convenient way to record the number of days and/or miles you ride.

If you do not feel capable of performing a given task or need assistance, remember that your Honda dealer knows your motorcycle best and is fully equipped to maintain and repair it. If you decide to do your own maintenance, use only Honda Genuine Parts or their equivalents for repair or replacement to ensure the best quality and reliability.

Perform the pre-ride inspection (page 22) at each scheduled maintenance period. Each item on the maintenance schedule requires some mechanical knowledge. Certain items (particularly those marked * and **) may require more technical information and tools. Consult your dealer.

* Should be serviced by your dealer, unless the owner has the proper tools and service data and is mechanically qualified. Refer to the official Honda Service Manual.

**In the interest of safety, we recommend these items be serviced only by your dealer.

Summary of Maintenance Schedule Notes and Procedures:

NOTES:

1. Service more frequently when ridden in wet or dusty conditions.

2. Replace every 2 years. Replacement requires mechanical skill.

Maintenance Procedures:

I: inspect and clean, adjust, lubricate, or replace, if necessary

C: clean

A: adjust

L: lubricate

R: replace

Maintenance Component Locations

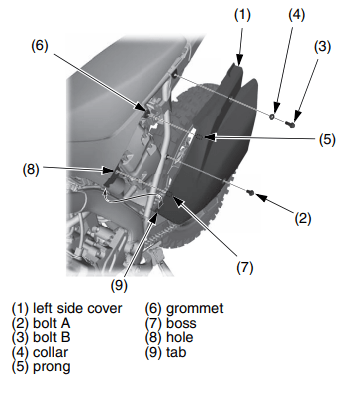

Left Side Cover Removal

The left side cover (1) must be removed to service the air cleaner and sub fuse.

Left Side Cover Removal

- Remove the bolt A (2), bolt B (3) and collar (4).

- Pull out the prong (5) from the rubber grommet (6), and the boss (7) from the hole (8) on the shroud.

Left Side Cover Installation

- Hook the tab (9) to the shroud and slide the top of the side cover under the bottom edge of the seat.

- Align the prong with the rubber grommet, and also the boss with the hole on the shroud.

- Install the collar onto the bolt B.

- Install the bolt B and bolt A and tighten them securely

Fuel

Fuel Recommendation

Your engine is designed to use any unleaded gasoline that has a pump octane number of 86 or higher. Gasoline pumps at service stations normally display the pump octane number.

Use of lower octane gasoline can cause persistent ‘‘pinging’’ or ‘‘spark knock’’ (a louder rapping noise) which, if severe, can lead to engine damage. (Light pinging experienced while operating under a heavy load, such as climbing a hill, is no cause for concern.)

If pinging or spark knock occurs at a steady engine speed under normal load, change brands of gasoline. If pinging or spark knock persists, consult your dealer.

Use only unleaded fuel in your Honda. If you ride your Honda in a country where leaded fuel might be available, take precautions to use only unleaded fuel.

Never use stale or contaminated gasoline or an oil/gasoline mixture. Avoid getting dirt, dust, or water in the fuel tank.

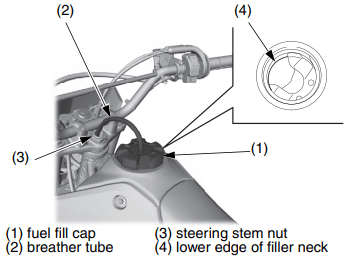

Refueling Procedure

Fuel Tank Capacity: 0.98 US gal (3.7l )

- To open the fuel fill cap (1), pull the breather tube (2) out of the steering stem nut (3). Turn the fuel fill cap counterclockwise and remove it.

- Add fuel until the level reaches the lower edge of the filler neck (4). Avoid overfilling the tank. There should be no fuel in the filler neck

- After refueling, turn the fuel fill cap clockwise until it clicks.

- Insert the breather tube in the steering stem nut.

If you replace the fuel fill cap, use a Honda Genuine replacement part or equivalent.

Engine Oil

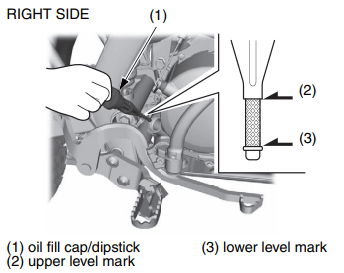

Checking & Adding Oil

1. Park your motorcycle on a firm, level surface.

2. Clean around the oil fill cap/dipstick (1) and nearby surfaces.

3. Start the engine and let it idle for 3-5 minutes. Stop the engine. Wait 2-3 minutes.

4. Unscrew and remove the oil fill cap/dipstick. Wipe it clean.

5. Hold the motorcycle upright.

6. Insert the oil fill cap/dipstick until it seats, but do not screw it in.

7. Remove the oil fill cap/dipstick and check the oil level.

- If the oil is at or near the upper level mark (2), you do not have to add oil.

- If the oil is below or near the lower level mark (3), add the recommended oil until it reaches the upper level mark. (Do not overfill.)

8. Insert the oil fill cap/dipstick and screw it in tightly.

9. Check for oil leaks.

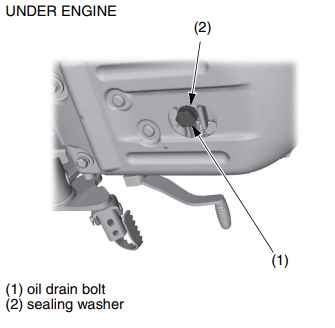

Changing Engine Oil

1. If the engine is cold, start it and let it idle for 3-5 minutes. Turn the engine off. Wait 2-3 minutes for the oil to settle.

2. Park your motorcycle on its side stand on a firm, level surface.

3. Place a drain pan under the crankcase.

4. To drain the oil, remove the oil fill cap/ dipstick, oil drain bolt (1), and sealing washer (2).

5. Pour the drained oil into a suitable container and dispose of it in an approved manner

6. After the oil has drained, install the drain bolt with new sealing washer and tighten to the specified torque: 18 lbf·ft (24 N·m , 2.4 kgf·m)

7. Pour the recommended oil into the crankcase, approximately: 0.9 US qt (0.85 )

8. Install the oil fill cap/dipstick securely.

9. Start the engine and let it idle for 3-5 minutes. Stop the engine. Wait 2-3 minutes.

10.With the motorcycle held upright on level ground, check the oil level. If needed, add oil (page 64) until it reaches the upper level mark. (Do not overfill.)

11.Check for oil leaks.

Air Cleaner

Proper air cleaner maintenance is very important for off-road vehicles. A dirty, water-soaked, worn-out, or defective air cleaner will allow dirt, dust, mud, and other impurities to pass into the engine.

Service the air cleaner more frequently if you ride in unusually wet or dusty areas. Your dealer can help you determine the correct service interval for your riding conditions.

Your motorcycle’s air cleaner has very specific performance requirements.

Use a new Honda Genuine air cleaner specified for your model or an air cleaner of equal quality.

NOTICE Using the wrong air cleaner may result in premature engine wear.

Proper air cleaner maintenance can prevent premature engine wear or damage, expensive repairs, low engine power, poor gas mileage, and spark plug fouling.

Cleaning

1. Remove the left side cover .

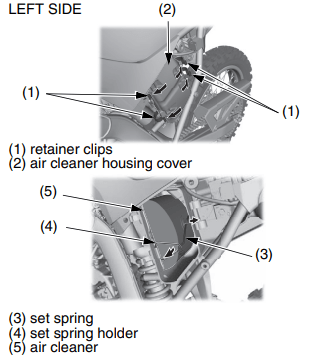

2. Unlatch the retainer clips (1) and remove the air cleaner housing cover (2).

3. Unhook the set spring (3), take care to avoid bending the set spring and set spring holder (4).

4. Remove the air cleaner (5).

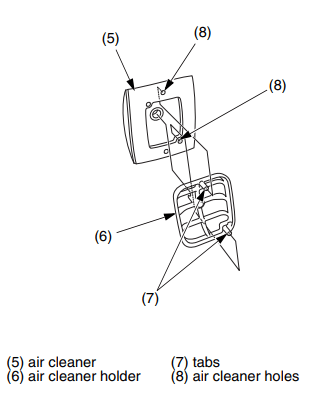

5. Remove the air cleaner holder (6) from the air cleaner (5).

6. Gently wash the air cleaner in clean, nonflammable (high flash point) solvent such as kerosene–not gasoline. After cleaning, gently squeeze out the remaining solvent. Avoid twisting or wringing the air cleaner. This can tear the foam.

7. Inspect for tears or cracks in the foam or seams of the air cleaner. Replace the air cleaner if it is damaged.

8. Allow the air cleaner to dry thoroughly before applying oil. A wet air cleaner will not fully absorb the oil.

9. Pour clean Pro Honda Foam Filter Oil or an equivalent (Canada: Honda Foam Filter Oil or an equivalent) over the entire surface of the air cleaner. Use both hands to evenly spread the oil into the air cleaner. Gently squeeze out any excess oil. (To keep your hands dry, place the air cleaner in a clean plastic bag before spreading the oil into the air cleaner.)

10.Assemble the air cleaner and holder. Insert the tabs (7) in the air cleaner holes (8).

11.Clean the inside of the air cleaner housing.

12.Apply a thin coat of grease to the sealing surface of the air cleaner.

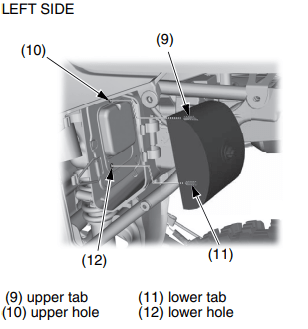

13.Install the air cleaner assembly by inserting the upper tab (9) on the cleaner into the upper hole (10) in the air cleaner housing, and the lower tab (11) into the lower hole (12). Hook the set spring. Check that the air cleaner is properly seated.

14.Install the air cleaner housing cover and set the retainer clips.

15.Install the left side cover

Crankcase Breather

Service more frequently if your motorcycle is ridden in the rain or often at full throttle. If the drain tube overflows, the air filter may become contaminated with engine oil causing poor engine performance.

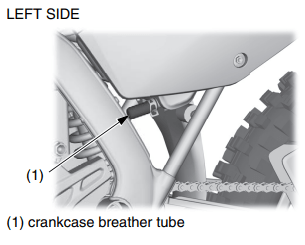

1. Place a suitable container under the crankcase breather tube.

2. Remove the crankcase breather tube (1).

3. Drain deposits into a suitable container.

4. Install the crankcase breather tube.

Throttle

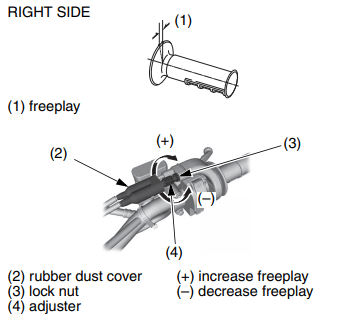

Throttle Freeplay

Inspection

Check freeplay (1).

Freeplay: 1/16 – 1/4 in (2 – 6 mm)

If necessary, adjust to the specified range.

Adjustment

1. Pull the rubber dust cover (2) back.

2. Loosen the lock nut (3) on the throttle cable mechanism.

3. Turn the adjuster (4).

4. Tighten the lock nut. Return the dust cover to its normal position.

5. After adjustment, check for smooth rotation of the throttle grip from fully closed to fully open in all steering positions.

If you can’t get the freeplay within the specified range, contact your dealer.

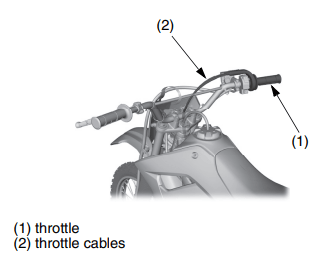

Throttle Inspection

1. Check that the throttle assembly is positioned properly and the securing bolts are tight.

2. Check for smooth rotation of the throttle (1) from fully open to fully closed in all steering positions. If there is a problem, see your dealer

3. Inspect the condition of the throttle cables (2) from the throttle grip down to the throttle body. If the cable is kinked or chafed, have it replaced.

4. Check the cables for tension or stress in all steering positions.

5. Lubricate the cables with a commercially available cable lubricant to prevent premature rust and corrosion.

Clutch System

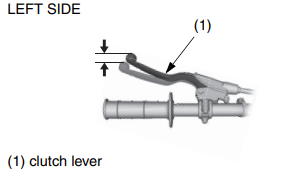

Clutch Freeplay

Inspection

Check freeplay.

Freeplay: 3/8 – 13/16 in (10 – 20 mm)

If necessary, adjust to the specified range.

Improper freeplay adjustment can cause premature clutch wear.

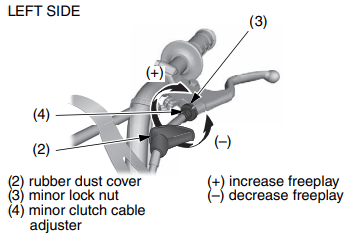

Minor Adjustment

Minor adjustments are generally made with the minor clutch cable adjuster.

Minor clutch assembly adjuster:

1. Pull the rubber dust cover (2) back.

2. Loosen the upper lock nut (3).

3. Turn the upper clutch cable adjuster (4) to obtain the specified freeplay.

4. Tighten the lock nut and check the freeplay again.

5. Return the dust cover to its normal position.

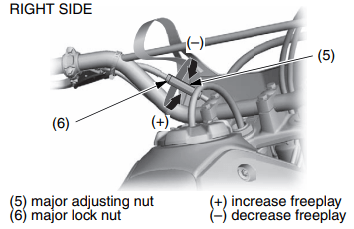

Major Adjustment

The lower clutch cable adjuster is used if the upper clutch cable adjuster is threaded out near its limit, or the correct freeplay cannot be obtained.

1. Loosen the minor lock nut (3) and turn the minor clutch cable adjuster (4) all the way in (to provide maximum freeplay).

2. Tighten the minor lock nut and pull the rubber dust cover (2) back to its normal position.

3. Hold the major adjusting nut (5) and loosen the major lock nut (6).

4. Turn the major adjusting nut to obtain the specified freeplay.

5. Hold the major adjusting nut and tighten the major lock nut. Check the adjustment.

6. Start the engine, pull the clutch lever in, and shift into gear. Make sure the engine does not stall and the motorcycle does not creep. Gradually release the clutch lever and open the throttle. Your motorcycle should move smoothly and accelerate gradually.

If you can’t get proper adjustment, or the clutch does not work properly, the cable may be kinked or worn, or the clutch discs may be worn. See your dealer or refer to the official Honda Service Manual

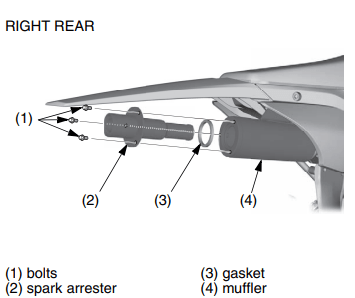

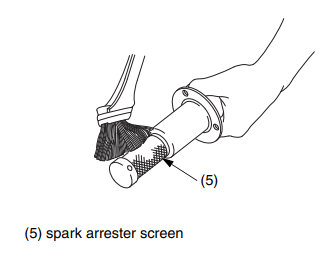

Spark Arrester

The spark arrester must be serviced every 100 operating hours to maintain its efficiency.

Regular servicing prevents carbon buildup (which can diminish engine performance) and also complies with USDA regulations for regular maintenance to assure proper function. The spark arrester prevents random sparks from the combustion process in your engine from reaching the environment.

1. Allow the engine and muffler to cool.

2. Remove the bolts (1), the spark arrester (2), and the gasket (3) from the muffler (4).

3. Use a brush to remove carbon deposits from the spark arrester screen (5). Be careful to avoid damaging the spark arrester screen. The spark arrester must be free of breaks and holes. Replace, if necessary.

4. Install the spark arrester with a new gasket and tighten the bolts to the specified torque: 7 lbf·ft (10 N·m , 1.0 kgf·m)

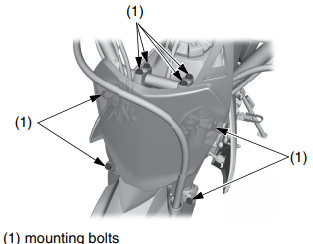

Suspension

Front Suspension Inspection

1. Check fork operation. Pull the front brake lever in, to lock the brake. Then pump up and down on the fork legs several times. The suspension should function smoothly. There should be no oil leakage.

2. Check the security of all handlebar and fork mounting bolts (1). If any front suspension components appear worn or damaged, see your dealer for further inspection.

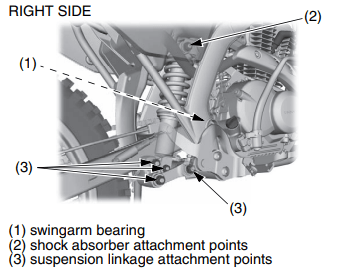

Rear Suspension Inspection

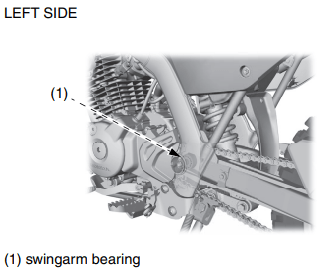

1. Place the motorcycle on a maintenance stand. Push hard against the side of the rear wheel and feel for any freeplay which indicates worn swingarm bearings (1).

2. Check that the fasteners for the shock absorber attachment points (2) and rear suspension linkage attachment points (3) are secure.

3. Check for oil leaks in the shock absorber. If any rear suspension components appear worn or damaged, see your dealer for further inspection.

Brakes

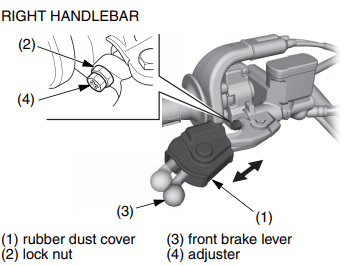

Front Brake Lever Adjustment

Never use adjusters other than those designed for this motorcycle. Install a new adjuster from the lever side with the lock nut under the head of the adjuster.

1. Pull the rubber dust cover (1) back.

2. Loosen the lock nut (2).

3. To position the front brake lever (3) farther away from the handgrip, turn the adjuster (4) clockwise. To position the front brake lever closer to the handgrip, turn the adjuster counterclockwise.

4. Tighten the lock nut. Return the dust cover to its normal position.

5. Apply the brake, release it, then spin the wheel and check that it rotates freely. Repeat this procedure several times.

6. Check freeplay by pulling in slowly on the front brake lever until the brake starts to engage. Freeplay: LESS THAN 13/16 in (20 mm)

If brake lever freeplay is not within this range, see your dealer.

Fluid Level Inspection

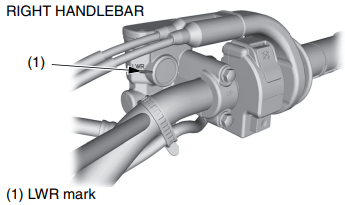

Front Brake Fluid Level

With the motorcycle in an upright position, check the fluid level. It should be above the LWR mark (1). If the level is at or below the LWR mark, check the brake pads for wear

Worn brake pads should be replaced. If the pads are not worn, have your brake system inspected for leaks. The recommended brake fluid is Honda DOT 3 or DOT 4 brake fluid from a sealed container, or an equivalent

Wipe up spills immediately. Avoid brake fluid contact with skin or eyes. If it comes in contact with your eyes, wash them out with clean water and immediately call a doctor. If it comes in contact with your skin, wash with clean water and, if necessary, call a doctor.

Other Inspections

- Make sure there are no fluid leaks.

- Check for deterioration or cracks in the hoses and fittings.

Rear Brake Fluid Level

Inspection

1. Place your motorcycle on its side stand.

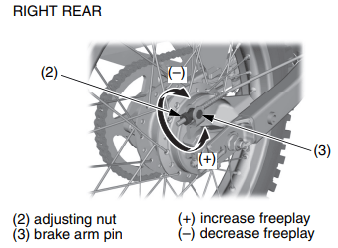

2. Check freeplay by slowly depressing the rear brake pedal (1) until the brake starts to engage.

Freeplay: 3/8–13/16 in (10–20 mm) If necessary, adjust to the specified range.

Adjustment

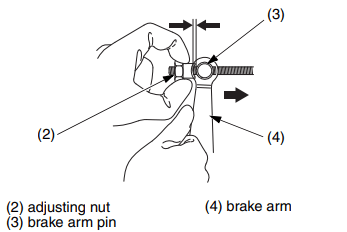

1. Adjust by turning the rear brake adjusting nut (2) a half-turn at a time. Make sure the cut out on the adjusting nut is seated on the brake arm pin (3).

2. Apply the brake, release it, and then spin the wheel and check that it rotates freely. Repeat this procedure several times.

3. Check the freeplay. If you can’t adjust the freeplay properly, see your dealer.

After adjustment, push the brake arm (4) to confirm that there is a gap between the adjusting nut (2) and the brake arm pin (3).

After adjustment, confirm the freeplay of the brake pedal.

Wheels

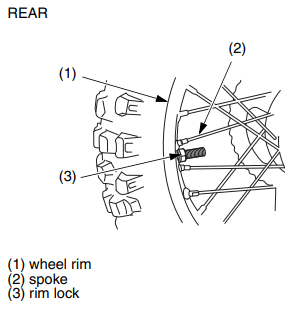

Wheel Rims & Spokes

1. Inspect the wheel rims (1) and spokes (2) for damage.

2. Tighten any loose spokes or rim locks (3).

3.Rotate the wheel slowly to see if it appears to ‘‘wobble.’’ If it does, the rim is out of round or not ‘‘true.’’ If the wobble is noticeable, see your dealer for inspection.

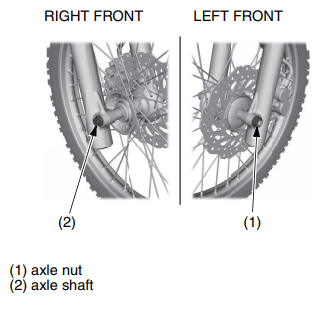

Front Wheel Removal

Removal

1. Raise the front wheel off the ground by placing a maintenance stand or support block under the engine. Secure the rear of the motorcycle with tie-down straps.

2. Remove the axle nut (1).

3. Remove the axle shaft (2), wheel, and side collars. Avoid depressing the brake lever when the wheel is off the motorcycle. This will force the caliper pistons out of the cylinders. The result will be loss of brake fluid. If this occurs, the brake system will require service. See your dealer for this service.

Avoid getting grease, oil, or dirt on the disc or pad surfaces. Any contamination can cause poor brake performance or rapid pad wear after reassembly.

Installation

1. Reverse the removal procedure. Install the side collars into the wheel. Carefully fit the brake disc between the pads to avoid scratching them.

2. Insert the front axle shaft from the right side, through the right fork leg and wheel hub.

3. Tighten the front axle nut to the specified torque: 46 lbf·ft (62 N·m , 6.3 kgf·m)

4. After installing the wheel, apply the brake several times and then check if the wheel rotates freely. Recheck the wheel if the brake drags or if the wheel does not rotate freely. Check front brake adjustment

If a torque wrench was not used to install the wheel, see your dealer as soon as possible to verify proper assembly. Improper assembly may lead to loss of braking capacity.

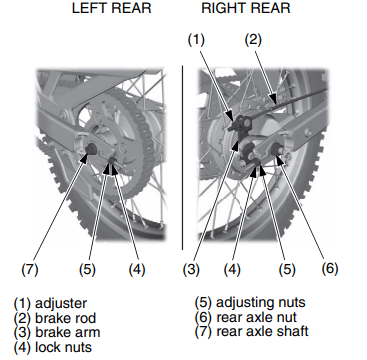

Rear Wheel Removal

Removal

1. Raise the rear wheel off the ground by placing a maintenance stand or support block under the engine. Secure the front of the motorcycle with tie-down straps.

2. Unscrew the rear brake adjuster (1). Press the rear brake pedal and disconnect the brake rod (2) from the brake arm (3).

3. Loosen the lock nuts (4) and adjusting nuts (5) on the chain adjuster on both sides.

4. Unscrew the rear axle nut (6). Pull the rear axle shaft (7) out. Push the wheel forward and derail the drive chain from the rear sprocket. Remove the wheel.

Take care to prevent getting grease, oil, or dirt on the brake shoe surfaces. This can cause poor brake performance or rapid brake shoe wear after reassembly.

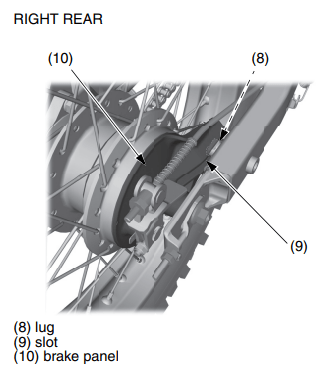

Installation

1.Reverse the removal procedure. Make sure the lug (8) on the swingarm is located in the slot (9) in the brake panel (10). Check that the chain adjusters are installed properly.

2. Adjust the drive chain

3. Tighten the rear axle nut to the specified torque: 46 lbf·ft (62 N·m , 6.3 kgf·m)

4. Adjust the rear brake

5. Apply the rear brake, release it, then spin the wheel and check that it rotates freely. Repeat this procedure several times.

If a torque wrench was not used to install the wheel, see your dealer as soon as possible to verify proper assembly. Improper assembly may lead to loss of braking capacity.

Tires & Tubes

Air Pressure

Properly inflated tires provide the best combination of handling, tread life, and riding comfort. Generally, underinflated tires wear unevenly, adversely affect handling, and are more likely to fail from being overheated. Underinflated tires can also cause wheel damage in rocky terrain. Overinflated tires make your motorcycle ride harshly, are more prone to damage from surface hazards, and wear unevenly. Make sure the valve stem caps are secure. If necessary, install new caps.

Always check air pressure when your tires are ‘‘cold.’’ If you check air pressure when your tires are ‘‘warm’’ – even if your motorcycle has only been ridden for a few miles – the readings will be higher. If you let air out of warm tires to match the recommended cold pressures, the tires will be underinflated. The correct ‘‘cold’’ tire pressures are:

Front 15 psi (100 kPa, 1.0 kgf/cm2)

Rear 15 psi (100 kPa, 1.0 kgf/cm2)

If you decide to adjust tire pressures for a particular riding condition, make changes a little at a time.

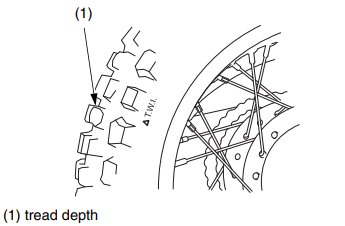

Inspection

A flat tire or blowout is inconvenient and may even cause a crash. Take time to inspect your tires and wheels before you ride. For more information about handling flat tires

- Inspect carefully for bumps or bulges in the side of the tire or the tread. Replace any tire that has a bump or bulge.

- Look closely for cuts, slits, or cracks in the tires. Replace a tire if you can see fabric or cord.

- Check for rocks or other objects embedded in the tire or tread. Remove any objects.

- Measure tread depth (1). Replace the tire before depth at the center reaches 0.12 in (3 mm), or any time you notice a reduction in traction.

- Check the position of both valve stems. A tilted valve stem indicates the tube is slipping inside the tire or the tire is slipping on the rim. See your dealer.

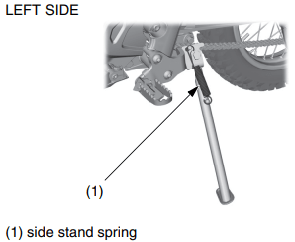

Side Stand

1. Check the side stand spring (1) for damage and loss of tension.

2. Check the side stand assembly for freedom of movement.

If the side stand is stiff or squeaky, clean the pivot area and lubricate the pivot bolt with clean engine oil.

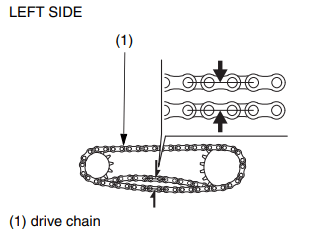

Drive Chain

Inspection

1. Check slack in the lower drive chain (1) run midway between the sprockets. Drive chain slack should allow the following vertical movement by hand: 1–1 3/8 in (25–35 mm)

2. Check drive chain slack at several points along the chain. The slack should remain constant. If it isn’t, some links may be kinked and binding. Lubricating the chain will often eliminate binding and kinking.

3. Inspect the drive chain for:

- damaged rollers

- loose pins

- dry or rusted links

- kinked or binding links

- excessive wear

- damaged or missing O-rings

Replace the drive chain if it has damaged rollers, loose pins, or kinks that cannot be freed. Lubricate the drive chain if it appears dry or shows signs of rust. Lubricate any kinked or binding links and work them free. Adjust chain slack if needed.

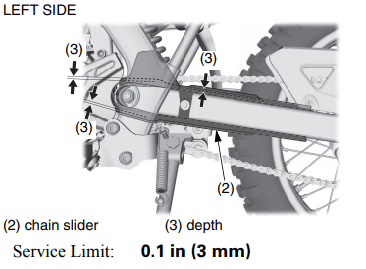

4. Check the chain slider (2) for wear. If the depth (3) of the chain slider reaches the service limit, have your dealer replace the chain slider.

5. Replace the drive chain if chain slack is excessive when the rear axle is moved to the farthest limit of adjustment. Excessive slack indicates the chain is worn beyond its service limit

To check the chain’s service limit, measure the distance between a span of 41 pins, from pin center to pin center. If the distance exceeds the service limit, the drive chain is worn out and should be replaced.

This motorcycle has a staked master link drive chain which requires a special tool for cutting and staking. Do not use an ordinary master link with this chain

6. Inspect the front and rear sprocket teeth for excessive wear or damage. If necessary, have your dealer replace a worn sprocket.

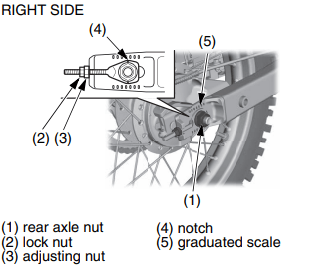

Adjustment

1. Loosen the rear axle nut (1).

2. Loosen the lock nuts (2) on both sides of the swingarm.

3. Turn the adjusting nuts (3) on the right and left chain adjusters an equal number of turns to increase or decrease chain slack.

4. Align the notches (4) on the chain adjusters with the graduated scales (5) on both sides of the swingarm.

5. Torque the rear axle nut to: 46 lbf·ft (62 N·m , 6.3 kgf·m) If a torque wrench is not used for this installation, see your dealer as soon as possible to verify proper assembly.

6. Tighten the adjusting nuts lightly. Then, while holding the adjusting nuts with a wrench, tighten the lock nuts.

7. Recheck drive chain slack.

8. Check rear brake pedal freeplay and adjust as necessary (page 88). Freeplay is affected when repositioning the rear wheel to adjust drive chain slack.

Battery

Your motorcycle has a maintenance-free type battery. You do not have to check the battery electrolyte level or add distilled water as you would with a conventional-type battery.

NOTICE Your battery is a maintenance-free type and can be permanently damaged if the cap strip is removed.

Electrical accessories use current from the battery, even when the ignition is OFF. Limited operation also allows the battery to discharge. If you have electrical accessories on your motorcycle or do not ride frequently, we recommend that you charge the battery frequently (see Battery Charging).

If you do not expect to ride your motorcycle for at least two weeks, we recommend you remove the battery, or at least disconnect the battery cables (negative cable first).

If you plan to store your motorcycle, see Battery Storage.

If your battery seems weak and/or is leaking electrolyte (causing slow starting or other electrical problems), see your dealer.

Battery Storage

If you plan to store your motorcycle, we recommend you remove the battery and store it where it can be charged at least every 30 days to maintain its service life.

If you do not remove the battery, we recommend disconnecting the battery cables (negative cable first).

You will get the best storage results from removing the battery and slow charging it every 30 days (see Battery Charging, page 114).

Before you remove the battery, be sure to read all the information that follows, as well as the information on the battery label.

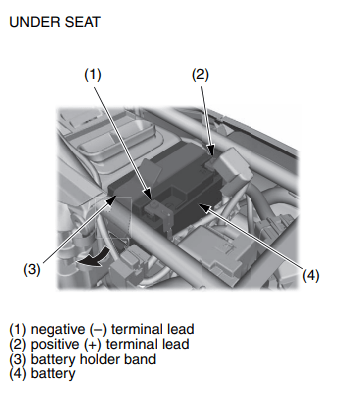

The battery is located in the battery compartment under the seat.

Removal

1. Make sure the ignition switch is OFF.

2. Remove the seat (pages 56).

3. Disconnect the negative (−) terminal (1) from the battery.

4. Disconnect the positive (+) terminal (2) from the battery.

5. Release the battery holder band (3) from the hook, then remove the battery (4) taking care not to drop the terminal nuts.

6. Charge the battery (see following section), unless you have been riding regularly.

7. Store your battery in an easy-to-reach location off the floor, in an area protected from freezing temperatures and direct sunlight.

8. Clean the battery box after removing the battery for storage.

9. Slow charge the battery (see following section) once every 30 days.

Installation

1. Reinstall in the reverse order of removal. Be sure to connect the positive (+) terminal first, then the negative (–) terminal.

2. Check all bolts and other fasteners are secure.

Battery Charging

Be sure to read the information that came with your battery charger and follow the instructions on the battery. Improper charging may damage the battery.

We recommend using a charger (1) designed specifically for your Honda, which can be purchased from your dealer. These units can be left connected for long periods without risking damage to the battery. However, do not intentionally leave the charger connected longer than the time period recommended in the charger’s instructions. Avoid using an automotive-type battery charger. An automotive charger can overheat a motorcycle battery and cause permanent damage.

Appearance Care

Frequent cleaning and polishing will keep your Honda looking newer longer. Frequent cleaning also identifies you as an owner who values your motorcycle. A clean motorcycle is also easier to inspect and service.

While you’re cleaning, be sure to look for damage, wear, and gasoline or oil leaks.

General Recommendations

- To clean your motorcycle, you may use:

- water

- a mild, neutral detergent and water

- a mild spray and wipe cleaner/polisher

- a mild spray and rinse cleaner/degreaser and water

- Avoid products that contain harsh detergents or chemical solvents that could damage the metal, paint, and plastic on your motorcycle.

- If your motorcycle is still warm from recent operation, give the engine and exhaust system time to cool off.

- We recommend the use of a low pressure garden hose to wash your motorcycle. High pressure washers (like those at coin-operated car washes) can damage certain parts of your motorcycle. If you use a high pressure washer, avoid spraying the following areas:

- wheel hubs

- muffler outlet

- area under seat

- engine stop button

- brake master cylinder

- under fuel tank

- drive chain

- throttle body

Washing Your Motorcycle with a Mild Detergent

1. Rinse your motorcycle thoroughly with cool water to remove loose dirt.

2. Fill a bucket with cool water. Mix in a mild, neutral detergent, such as dish washing liquid or a product made especially for washing motorcycles or automobiles.

3. Wash your motorcycle with a sponge or a soft towel. As you wash, check for heavy grime. If necessary, use a mild cleaner/ degreaser to remove the grime.

4. After washing, rinse your motorcycle thoroughly with plenty of clean water to remove any residue. Detergent residue can corrode alloy parts.

5. Dry your motorcycle with a chamois or a soft towel. Leaving water on the surface to air dry can cause dulling and water spots. As you dry, inspect for chips and scratches.

6. Lubricate the drive chain to prevent rusting.

7. Start the engine and let it idle for several minutes. The engine heat will help dry moist areas.

8. As a precaution, ride at a slow speed and apply the brakes several times. This will help dry the brakes and restore normal braking performance.

Exhaust Pipe and Muffler Maintenance

When the exhaust pipe and muffler are painted, do not use a commercially available abrasive kitchen cleaning compound. Use a neutral detergent to clean the painted surface on the exhaust pipe and muffler. If you are not sure if your exhaust pipe and muffler are painted, contact your dealer.

Taking Care of the Unexpected

General Guidelines

If something goes wrong during a ride, the first thing to do is stop as soon as you safely can. Do not continue riding if you have a flat tire, or you hear an unusual noise, or your motorcycle just doesn’t feel right. If you continue riding, you could cause more damage and endanger your own safety.

After a stop, take time to assess the situation. Carefully inspect your motorcycle to identify the problem, then consider your options before you decide what to do.

If a problem is relatively minor and you have the tools, supplies, and skills to make a permanent repair, you may be able to fix it on the trail and continue riding. Or, you may be able to make a temporary repair that allows you to slowly ride back to your base where you can make a permanent repair or get help.

When a problem is more serious – or you don’t have the tools, supplies, experience, or time to deal with it – you need to choose the safest way to get yourself and your motorcycle back to base. For example, if you are close enough, you (or you and another person) might be able to push it back.

Whatever the problem, the most important rules are:

- Always put personal safety first.

- If the problem is relatively minor and you have the tools, supplies, and skills to make a temporary repair, be sure to have permanent repairs made as soon as possible.

- Do not continue riding if you are hurt or your motorcycle is not in safe riding condition.

Additional recommendations for specific problems follow.

If Your Engine Quits or Won’t Start

Proper operation and maintenance can prevent starting and engine performance problems. In many cases, the cause of the problem may be a simple operational oversight.

If you have a problem starting the engine – or experience poor engine performance – the following information may help you. If you can’t correct the problem, see your dealer.

If your motorcycle won’t start, listen as you press the start button. If you don’t hear the starter motor turning, refer to the Starter motor doesn’t operate symptom. If you can hear the starter motor working normally, refer to the Starter motor works, but the engine won’t start symptom.

SYMPTOM: Starter motor doesn’t operate.

- ignition switch OFF

- Turn the ignition switch ON.

- transmission not in neutral

- Shift into neutral.

- blown fuse

- Replace with a new fuse of the same rating.

- battery lead loose

- Tighten the battery lead.

- low (or dead) battery

- Charge the battery. If charging doesn’t help, see your dealer.

- faulty starter motor

- If all possible causes are negative, the starter motor may be faulty. See your dealer.

SYMPTOM: Starter motor works, but the engine won’t start.

- out of fuel

- Fill the fuel tank.

- flooded engine

- See Flooded Engine.

- loose or unconnected spark plug cap

- Install the spark plug cap securely. If the engine still won’t start, see your dealer.

- loose battery cables

- Tighten the battery terminal bolts.

- weak battery

- Charge the battery. If charging doesn’t help, see your dealer

SYMPTOM: Engine starts, but runs poorly.

- idles roughly, too fast, stalls

- See your dealer.

- runs erratically, misfires

- See your dealer.

- blubbers (rich fuel mixture)

- See your dealer.

- sooty exhaust (rich fuel mixture)

- See your dealer.

- detonates or pings under load

- If applicable, switch to the recommended octane gasoline or change your brand of gasoline. If the problem persists, see your dealer.

- afterfires (backfires)

- See your dealer.

- pre-ignition (runs on after ignition switched OFF)

- See your dealer.

If You Have a Flat Tire

How you handle a flat tire on the trail depends on how serious the tube or tire damage is, and what tools and supplies you have with you.

If you have a slow leak or a minor puncture, there are two ways to try making a temporary repair:

- Use an aerosol tire sealer to seal the puncture and inflate the tube. (This can be done without removing the tire or wheel.)

- Use a tube patch kit to repair the puncture. (This requires removing the tire.)

If the leak is more serious, or a temporary repair doesn’t hold, the tube must be replaced. The tire will also need to be replaced if it is damaged. Replacing a tube or tire involves removing and re-installing the wheel.

If you are unable to repair a flat tire on the trail, you will need to push the motorcycle back to your base or send for help. We strongly recommend that you do not try to ride with a flat tire. The motorcycle will be hard to handle, and if the tire comes off the rim, it may lock up the wheel and cause you to crash

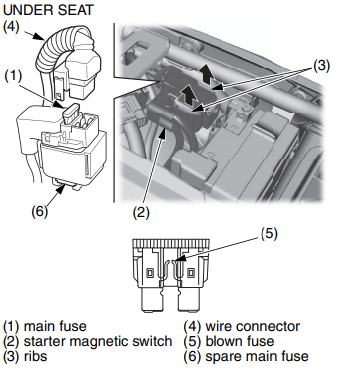

If a Fuse Blows

All of the electrical circuits on your motorcycle have fuses to protect them from damage caused by excess current flow (short circuit or overload).

If something electrical on your motorcycle stops working, the first thing you should check for is a blown fuse.

Check the fuses before looking elsewhere for another possible cause of the problem. Replace any blown fuse and check component operation.

The main fuse and sub fuse are located behind the left side cover.

Recommended Fuses

main fuse 10 A

sub fuse 5 A

1. To prevent an accidental short circuit, turn the ignition switch OFF before checking or replacing the fuse.

Main Fuse Access:

2. For access the main fuse (1), remove the seat

3. Remove the starter magnetic switch (3) from the ribs (4) of the battery box.

4. Disconnect the wire connector (5) of the starter magnetic switch.

5. Pull the fuse out. If the main fuse is blown (6), install the spare main fuse (7).

6. Reconnect the wire connector.

7. Install the starter magnetic switch.

8. Install the seat.

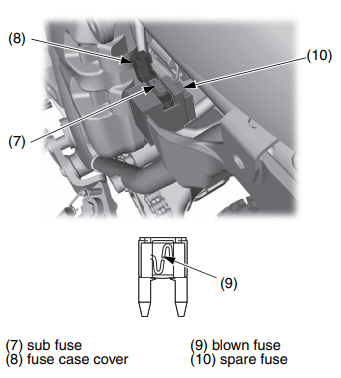

Sub Fuse Access:

9. For access the sub fuse (7), remove the left side cover

10. Open the fuse case cover (8) and pull the sub fuse out. If the fuse is blown (9), replace it with the spare fuse (10).

11. Close the fuse case cover and install the left side cover.

If you do not have a replacement fuse with the proper rating for the circuit, install one with a lower rating.

If You Crash

Personal safety is your first priority after a crash. If you or anyone else has been injured, take time to assess the severity of the injuries and whether it is safe to continue riding. If you cannot ride safely, send someone for help. Do not ride if you will risk further injury.

If you decide that you are capable of riding safely, first evaluate the condition of your motorcycle. If the engine is still running, turn it off and look it over carefully; inspect it for fluid leaks, check the tightness of critical nuts and bolts, and secure such parts as the handlebar, control levers, brakes, and wheels.

If there is minor damage, or you are unsure about possible damage but decide to try riding the motorcycle back to your base, ride slowly and cautiously.

Sometimes, crash damage is hidden or not immediately apparent. When you get home, thoroughly check your motorcycle and correct any problems you find. Also, be sure to have your dealer check the frame and suspension after any serious crash.

If You Lose Your Key

Be sure to record the key number provided with the original keys. Store the spare key and recorded key number in a safe location. You’ll need this number to have a duplicate key made.

If you lose your key and aren’t carrying a duplicate, either get your spare or have one made. If you don’t know your key number, call the dealer where you purchased your Honda. They may have it listed in their records. If they don’t, transport your motorcycle to them or the nearest dealer. The dealer will probably have to remove the ignition switch assembly to find the key number so they can make a key for you.

If a Component Fails

The drive chain, brake lever or pedal, control cables, and other components can be damaged as you ride in dense brush or over rocky terrain. Making a trailside repair depends on how serious the damage is and what tools and supplies you have with you.

- If the chain breaks or does other damage when it comes off, you may not be able to make a trailside repair.

- If any component of the front brake system is damaged, you may be able to ride carefully back to your base using the rear brake for slowing or stopping.

- If the clutch lever breaks, you may be able to temporarily switch the front brake lever to the clutch side, then ride carefully back to base using the rear brake for slowing or stopping.

- If you damage a throttle cable or other critical component, your motorcycle may be unsafe to ride. Carefully assess the damage and make any repairs that you can. But if there is any doubt, it’s best to be conservative and safe.

If Your Battery Is Low (or Dead)

Jump starting is not recommended, especially if you use an automobile battery. The greater amperage of an automobile battery when the car engine is running can damage your motorcycle’s electrical system.

Bump starting is also not recommended.

If you can’t charge the battery or it appears unable to hold a charge, contact your dealer.

If Unstable Engine Operation Occurs Intermittently

If the fuel pump filter is clogged, unstable engine operation will occur intermittently while riding.

Even if this symptom occurs, you can continue to ride your motorcycle. If unstable engine operation occurs even if sufficient fuel is available, have your motorcycle inspected by your dealer as soon as possible.

See other models: 2021 ADV150 2021 CBR1000RR-R FIREBLADE SP 2021 SUPER CUB C125 2020 PCX150 2020 GROM