Loading ...

Loading ...

Loading ...

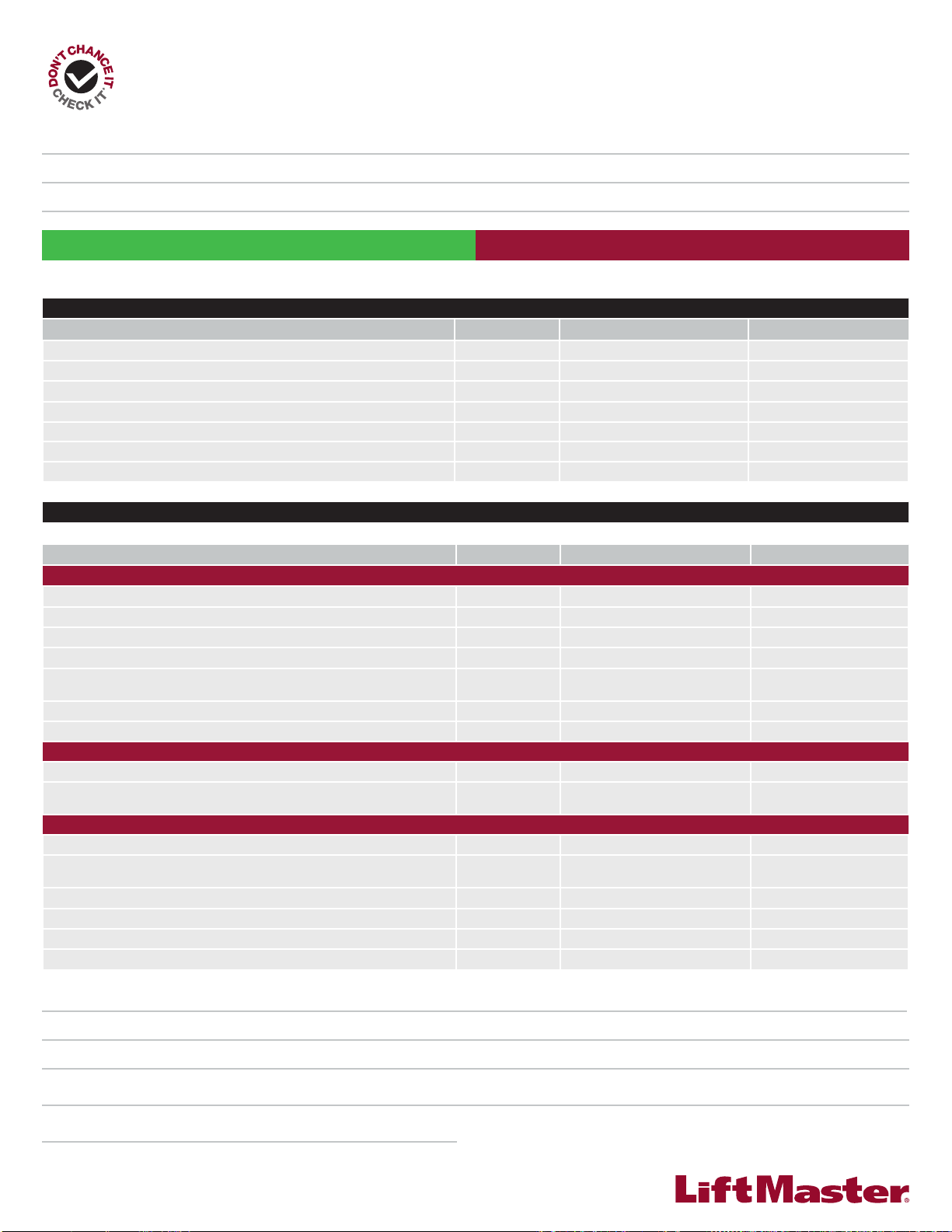

Swing and Slide Gate Operator UL 325 and

ASTM F2200 Site Planning Safety Checklist

Name:

Address:

City/State/ZIP:

Phone:

Email:

Please Print

ASTM F2200 Standards

Gate Construction Evaluation: Gate Constructed with Safety in mind. ASTM F2200 Standards are followed

Component: Result (Circle) Comments: Figures (On Back)

All Gates

Gates have smooth bottom edges, no protrusions exceed 1/2” beyond base of gate Pass / Fail

5

All access controls at least 6 ft. from gate Pass / Fail

1,4

Barbed tape (razor wire) at least 8 ft. above grade Pass / Fail

Barbed wire at least 6 ft. above grade Pass / Fail

Separate pedestrian gate – out of reach of a moving gate – vehicular gate is

for automotive traffic only

Pass / Fail

1,4

Gate does not move on its own if disconnected from operator Pass / Fail

Gates prevented from falling over if disconnected from supporting hardware Pass / Fail

SWING

Distance from pivot point to column edge is less than 4 in. Pass / Fail

4

Distance from open gate to wall or column greater than 16 in. or external

entrapment protection is provided

Pass / Fail

4

SLIDE

Roller covers on wheels Pass / Fail

1

Meshing installed up to 6 ft. above grade if pickets spaced equal to or

greater than 2 1/4 in. apart

Pass / Fail

3

Gap between gate and fence post less than 2 1/4 in. & gap protected with safety device Pass / Fail

2

Positive stops at both fully open and fully closed positions Pass / Fail

1

Receiver guides recessed behind receiver post for receiver guides less than 8 ft. Pass / Fail

Other: Pass / Fail

© 2018 LiftMaster All Rights Reserved

300 Windsor Drive, Oak Brook, IL 60523

LMSPCLSWSL 4/18

Please Print

First & Last Name of Dealer:

Name of Dealership:

Dealership Address (Street Address/City/State/Zip):

Dealer Signature:

Customer Signature:

First & Last Name of Installer:

Phone:

Installer Signature:

Satisfactory

Needs Repair/Replacement

Gate Safety Check —

Simple steps to quickly determine if an End User’s gate operator is safe.

UL 325 Standard

Component: Result (Circle) Comments: Figures (On Back)

1. Gate Operator is approved to current UL 325 standards (check operator label) Pass / Fail

2. Proper gate warning signs attached to both sides of gate area Pass / Fail

1,4

3. All entrapment zones protected by 2 safety devices/obstruction tested

1,4

Close Side (circle two) Photo Eye

Reversing Edge Inherent Reverse

Pass / Fail

Open Side

(circle two) Photo Eye

Reversing Edge Inherent Reverse

Pass / Fail

Other Entrapment Areas

Pass / Fail

UL 325 Installation Class (

circle one) I II III VI

*Entrapment Zone: The location where an object can be caught or held in a position that increases the risk of injury

381327 LMSPCLSWSL_F.indd 1 5/2/18 7:33 PM

Loading ...

Loading ...