Loading ...

Loading ...

Loading ...

14 15

TIPS FOR TRIMMING

Avoid hot surfaces by always keeping the product away from

your body.

Cut all grass from top to down. This will prevent grass from

wrapping around the shaft housing and string head which could

cause damage from overheating. If grass becomes wrapped

around the string head, STOP THE ENGINE, disconnect the

spark plug wire, and remove the grass.

Use the tip of line to trim grass; do not force string head into

uncut grass.

Avoid trees, flowers, stones, walls and other objects which can

cause the line breakage.

Check and feed the line regularly to maintain full cutting width

and performance.

OPERATION

CLEANING AND CARE

Correct and regular cleaning is not only important for the safe

use of this product, but also extends its life span.

WARNING. Always stop the engine and wait for the

engine to cool down.

Please remove dust, grass etc. from machine after every

application. Clean the machine with a wet cloth. For cleaning

difficult to reach areas, use a brush.

You may use pressurised air to remove persistent dust.

NOTE: Do not use chemical, acid, alkaline, grinding or other

aggressive cleaning agents. They could destroy the surface of

the product.

MAINTENANCE

WARNING.

Always stop the engine and wait for the

engine to cool down.

Disconnect spark plug wire and move it away from

spark plug.

When servicing, use only identical replacement parts. Use of

any other parts could create a hazard or cause product damage.

Always wear eye protection with side shields marked to comply

with ANSI Z87.1, along with hearing protection.

Failure to do so could result in objects being thrown into your

eyes and other possible serious injuries.

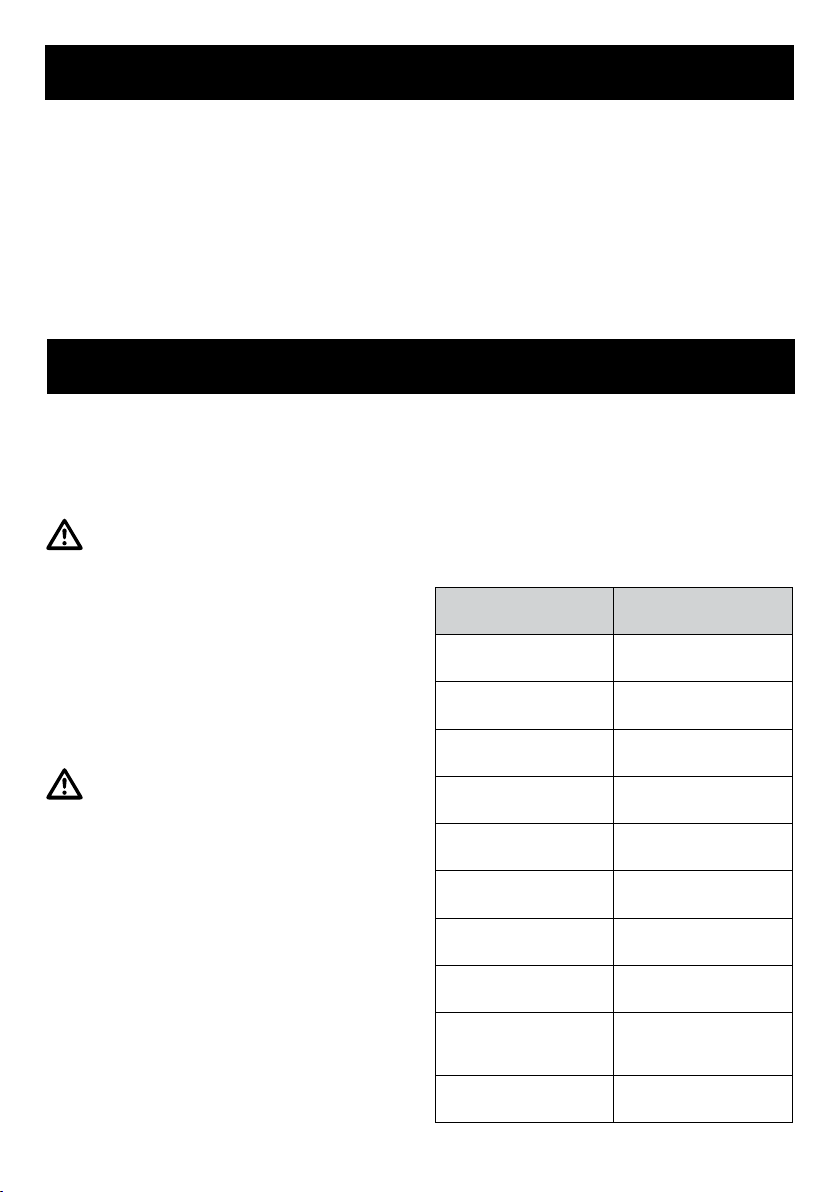

INSPECTION AND MAINTENANCE

SCHEDULE

The maintenance interval is only a recommendation for

machines in ordinary operating condition. If there are any

abnormal signs from the machine, please do the proper

inspection and maintenance immediately.

The tightening torque should follow the general screw

specification of different size, class and material.

If anything is unclear to you, please contact our service team for

help. See Page 2 or 4 for contact details.

All other repairs or maintenances which are not mentioned here

shall only be done by our service team or authorised service

agent.

MAINTENANCE

ITEM HOURS OF OPERATION

Engine lubricant oil level Every time before use

Loosened or lost screws Every time before use

Damage of any part Every time before use

Function of control elements Every time before use

Fuel level Every time before use

Leakage of oil or fuel Every time before use

Cutting line Every time before use

Engine oil replacement Every 20 hours

Air filter cleaning

Every 20 hours but every

10 hours if work condition

is dusty

Spark plug check Every 20 hours

Loading ...

Loading ...

Loading ...