Loading ...

Loading ...

Loading ...

5

Electrical connection

The connection of the hobs to mains is effected via the flex and the three pin plug located underneath the

hotplate. The appliance operate at a main voltage of 120V a.c., frequency 60Hz. Electric power absorption is

about 1W for 5 gas burner version or 2W for 6 gas burners version.

WARNING: Electrical Grounding Instructions: This appliance is equipped with a (three-prong)

grounding plug for your protection against shock hazard and should be plugged directly into a

properly grounded receptable. Do not cut or remove the grounding prong from this plug.

Wiring diagrams Wiring diagram description

see Fig. 12. 1. Cable terminal

2. Ignition switch

3. Spark generator

4. Ignition spark

L. Black

N. White

T. Green (earth)

Room ventilation – Location and venting.

ATTENTION: An exhaust fan may be used with the appliance; in each case it shall be installed in

conformity with the national standards in force.

ATTENTION: Exhaust hood operation may affect other vented appliances; in each case it shall be

installed in conformity with the national standards in force.

Conversion to different types of gas

Before carrying out any maintenance work, disconnect the appliance from the gas and electric

supply. For Natural Gas fit regulator assembly described in Fig. 5. For LP Gas fit assembly described

in fig. 5.

- CHANGING THE NOZZLES FOR USE WITH OTHER TYPES OF GAS:

To change the nozzles of the burners use the following procedure:

Lift up the burners and unscrew the nozzles ( Fig. 8) using an adjustable spanner of 7 mm and change the

nozzles with those designed for the new gas supply according to the information given in TABLE A shown

below.

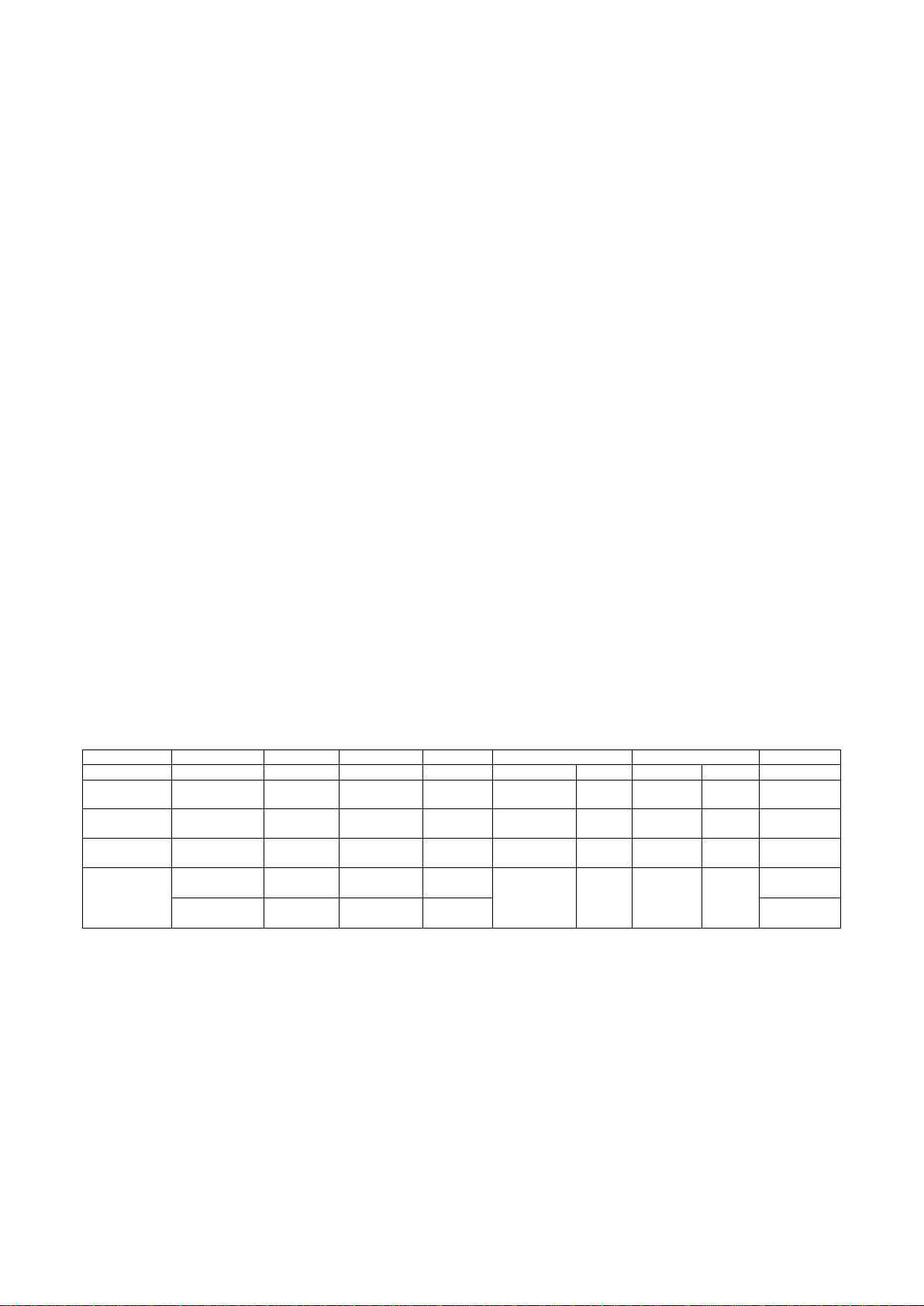

TABLE A: Adapting to different types of gas

Burner

Position Inj. size

Gas Pressure Max Rate Min Rate By-pass size

1/100mm

Type

[i.w.c.]

[BTU/h]

[W]

[BTU/h]

[W]

[1/100mm]

Auxiliary

Front R

92

NG

4”

3750

1098

900

264

Regulated

56

LP(Propane)

11”

3750

1098

900

264

29

Semi-Rapid

Rear L

117

NG

4”

6000

1759

1500

439

Regulated

73

LP(Propane)

11”

6300

1845

1500

439

36

Rapid

Rear R

155

NG

4”

10400

2046

2500

732

Regulated

98

LP(Propane)

11”

11400

3339

2500

732

47

Front L Inner

80

NG

4”

900 264

Regulated

Dual

50

LP(Propane)

11”

NG 17000

4980

29

burner

Front L Outer

N°2 x 130

NG

4”

LP 18800

5507

Regulated

N°2 x 83

LP(Propane)

11”

65

CAUTION: save the orifices removed from the appliance for future use

Regulation of burners

Regulation of the "MINIMUM" on the burners

To regulate the minimum on the burners carry out the following procedure indicated below:

1) Turn on the burner and put the knob onto position MINIMUM ( small flame ).

2) Remove the knob ( Fig. 9) of the tap which is set for standard pressure. The knob is found on the bar of

the tap itself.

3) Beside the tap bar on the work top, use a small screwdriver that fits the screw (gold) found on the lower

part of the tap (auxiliary, semirapid, rapid Fig. 9) (dual fig.10) and turn the fixing screw to the right or left until

the flame of the burner is regulated in the most suitable way to MINIMUM.

4) Make sure that that the flame does not go out when changing the position quickly from MAXIMUM to the

MINIMUM position.

ATTENTION: The regulation described above can be carried out only with burners using natural gas,

while with burners using propane gas the screw must be fully screwed in, in a clockwise direction.

Loading ...

Loading ...

Loading ...