Loading ...

Loading ...

Loading ...

ENGLISH

Installation Manual 77

Test Run

Maintenance of plate type heat exchanger

h When CH24 or CH180 error occurs during the test operation of the heater, the inside of the panel heat exchanger may be

partially frozen and therefore, be sure to get rid of its cause and then, re-operate the device.

(The root cause of partial freezing: The lack of flow of heat-sourced water, suspension of water, lack of cooling medium,

infiltration of foreign substance inside of panel heat exchanger )

As the scales are created in the panel heat exchanger, its efficiency may decrease or damage may occur due to winter-sowing due

to the decrease in its flow.

Due to this reason, regular maintenance is necessary so that the scales shouldn't be created.

1. Before the season of use, check below points.(Once a year)

1) inspection on water quality to check if this is within the standard condition.

2) Clean the strainer.

3) Check if the flow is appropriate.

4) Check if the operation environment is appropriate.(Pressure, flow, output temperature)

2. Below procedure should be abided by in order to clean the panel heat exchanger. (Once every 5 years)

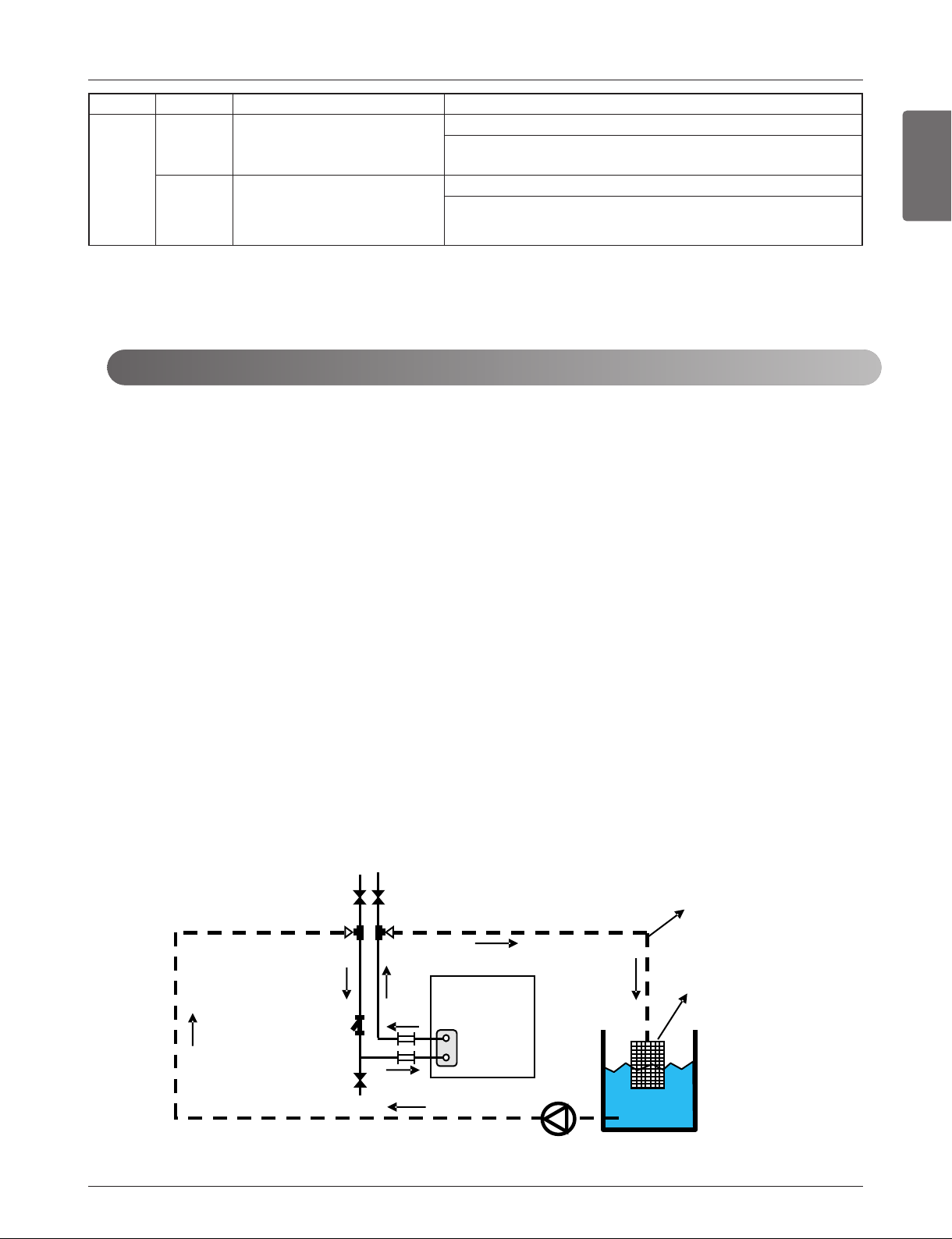

1) Check if the service port is equipped with the water pipe in order to clean the chemical solution.

5% diluted formic acid, citric acid, oxalic acid, acetate acid, phosphoric acid and etc. are appropriate for the chemical solution

for wiping out the scales.(Hydrochloric acid, sulphuric acid, nitric acid and etc. shouldn't be used due to its corrosion.)

2) Be sure to check if the gate valve of inflow/outflow pipe and the valve for outflow pipe are properly closed when cleaning.

3) Connect the water pipe for cleaning with the chemical solvent through the service plug of the pipe and fill up the panel heat

exchanger with 50°C~60°C(122°F~140°F) of cleaning solvent and circulate it with the pump for 2~5 hours. The circulation

time may depend on the temperature of the cleaning solvent or the creation of the scales. Therefore, observe change in the

color of the chemical solvent to set the circulation time for removing the scales.

4) After the circulation of the solvent, extract the solvent inside of the panel heat exchanger and fill up 1~2% of NaOH or NaHCO

3

and then, circulate it for 15~20 minutes to neutralize the heat exchanger.

5) Once the neutralization is completed, clean the inside of the panel heat exchanger with clean water.

Measure the water Ph to check if the chemical solvent is properly removed or not.

6) When using a different kind of chemical solvent in the market, be sure to check if there is any corrosive action to stainless or

copper in advance or not.

7) For details on the cleaning chemical solvent, be sure to consult the specialists of the related corporation.

3. After cleaning, operate the device to see if it works properly once again.

Gate valve(locked)

Service plug

Strainer

Outflow water

valve(locked)

Gate valve(locked)

Water-cooling

type multi V

Hose

Pump

[Cleaning the panel heat exchanger]

Screening net

Item

Phenomenon

Cause Checkpoint and resolution

Check whether heat source water supply pump is operating.

Check whether the heat source water supply pipe is clogged.

(Clean strainer, valve locked, valve issue, air trapped etc.)

Check whether heat source waterr supply pump is operating.

Check whether the heat source watersupply pipe is clogged.

(Clean strainer, valve locked, valve issue, air trapped etc.)

Whether

heat water

is supplied

Heat water not supplied or flow

rate is insufficient

Heat water not supplied or flow

rate is insufficient (During heat-

ing)

CH34

CH180

Loading ...

Loading ...

Loading ...