Loading ...

Loading ...

Loading ...

KNOWING YOUR SEWING MACHINE

—

———————————————————————————————————————

—

11

f

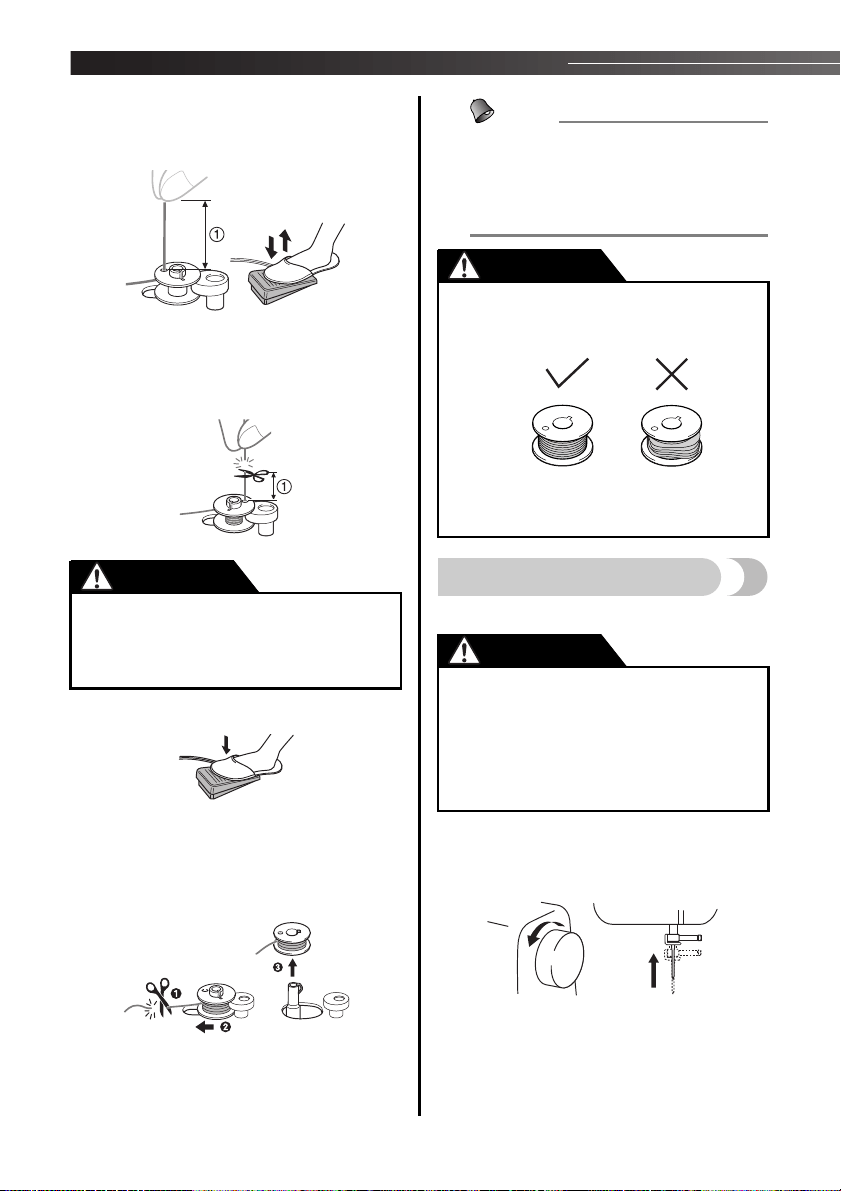

While holding the end of the thread, gently press

the foot controller to wind the thread around the

bobbin a few times. Then stop the machine.

a 7-10 cm (3-4 inches)

g

Trim the excess thread above the bobbin.

• Leave 1 cm (1/2 inch) of thread from the

hole on the bobbin.

a 1 cm (1/2 inch)

h

Press the foot controller to start.

i

When the bobbin seems full and begins

spinning slowly, take your foot off the foot

controller.

j

Cut the thread, slide the bobbin winder shaft

to the left and remove the bobbin.

Memo

●

When the sewing machine is started or the

handwheel is turned after winding the thread

around the bobbin, the machine will make a

clicking sound; this is not a malfunction.

● The needle bar does not move when you

slide the bobbin winding shaft to the right.

Lower threading

Install the bobbin wound with thread.

a

Raise the needle to its highest position by turning

the handwheel toward you (counterclockwise)

and raise the presser foot lever.

● Make sure you follow the instructions

carefully. If you do not cut the thread

completely, and the bobbin is wound, when

the thread runs low it may tangle around the

bobbin and cause the needle to break.

CAUTION

● Winding the bobbin improperly may cause

the thread tension to loosen, breaking the

needle and resulting in injury.

a Wound evenly

b Wound poorly

● Make sure you turn the power off while

threading the machine. If you accidentally

step on the foot controller and the machine

starts to sew, you could be injured.

● -“ Moving parts - To reduce the risk of injury.

Disconnect from supply circuit before

servicing. Remove cover.”

CAUTION

1

2

CAUTION

Loading ...

Loading ...

Loading ...