Loading ...

Loading ...

Loading ...

14 English

Continuous steaming: Pull the lock for the

“steam” switch backwards until it engages. Steam

flows out continuously. To release, push the lock

forward.

3. Before ironing and after pauses in the ironing pro-

cess, direct the blast of steam onto a cloth until the

steam flows evenly.

Dry ironing

ATTENTION

Damage to the device

Water shortage in the steam boiler leads to damage to

the device

Make sure that there is water in the steam boiler.

ATTENTION

Damage to garments

Failure to observe the ironing information in the garment

may result in damage.

Observe the ironing information in the garment.

1. Set the temperature controller of the iron in accord-

ance with the garment.

2. Wait until the iron’s heating indicator light goes out.

The iron is ready for ironing.

Care and service

Descaling the steam boiler

Note

Since the lime clogs the appliance, we recommend des-

caling the appliance based on the number of times the

water reservoir is filled as specified in the table (TF=tank

fillings).

Note

Your water board or municipal utilities authority can pro-

vide information on hardness of tap water.

ATTENTION

Damaged surfaces

The descaler may corrode sensitive surfaces.

Fill and empty the appliance carefully.

1. Switch off the appliance, see Chapter Switching off

the device.

2. Allow the appliance to cool down.

3. Drain the water reservoir.

4. Remove the accessory/accessories from the acces-

sory holders.

5. Open the cap of the accessory compartment.

6. Remove the accessory from the accessory compart-

ment.

7. Open the maintenance lock. To do this place the

open end of an extension tube on the maintenance

lock, insert this into the guide so it engages and

open it.

Illustration S

8. Drain the water completely out of the steam boiler.

Illustration T

ATTENTION

Appliance damage due to descaler

An unsuitable descaler or incorrect dosing of the descal-

er may damage the appliance.

Only use KÄRCHER descaler.

Use 1 dosing unit of the descaler for 0.5 l water.

9. Apply descaler solution to the descaler according to

the details.

10. Fill the descaler solution into the steam boiler. Do

not seal the steam boiler.

11. Allow the descaler solution to take effect for

approx. 8 hours.

12. Drain descaler solution completely out of the steam

boiler.

13. Repeat the descaling process if necessary.

14. Rinse the steam boiler 2-3 times with cold water in

order to drain all the descaler solution residue.

15. Drain the water completely out of the steam boiler.

16. Dry the mounting for the grid connection cable.

17. Close the maintenance lock with an extension tube.

Care of accessories

(Accessories - depending on scope of deliv

ery)

Note

The micro fibre cloths are not suitable for dryer.

Note

When washing the cloths, observe the instructions on

the washing tag. Do not use any liquid softeners as

this will affect the ability of the cloths to pick up dirt.

1. Wash the floor cleaning cloths and covers at a

___max. temperature of 60 °C in the washing

___machine.

Troubleshooting guide

Malfunctions often have simple causes that you can

remedy yourself using the following overview. When in

doubt, or in the case of malfunctions not mentioned

here, please contact your authorised Customer Service.

몇 WARNING

Risk of electric shock and burns

Trying to eliminate faults while the appliance is connect-

ed to the mains or has not yet cooled down is always

dangerous.

Remove the mains plug.

Allow the appliance to cool down.

The water shortage indicator light flashes red and a

signal tone sounds

No water in the tank.

Fill the water reservoir up to the “MAX” marking.

The water shortage indicator light is lit in red

No water in the steam boiler. The pump’s overheat pro-

tection has triggered.

1. Switch the device off; see Chapter Switch off the de-

vice.

2. Fill the water reservoir.

3. Switch on the device; see Chapter Switching on the

device.

The water tank is not inserted correctly or is calcified.

1. Remove the water reservoir.

2. Rinse the water reservoir.

3. Insert the water reservoir and press downwards until

it locks into place.

The steam lever cannot be pressed

The steam lever is locked with the child lock.

Set the child lock to the front.

The steam lever is released.

Synthetics

Wool, silk

Cotton, linen

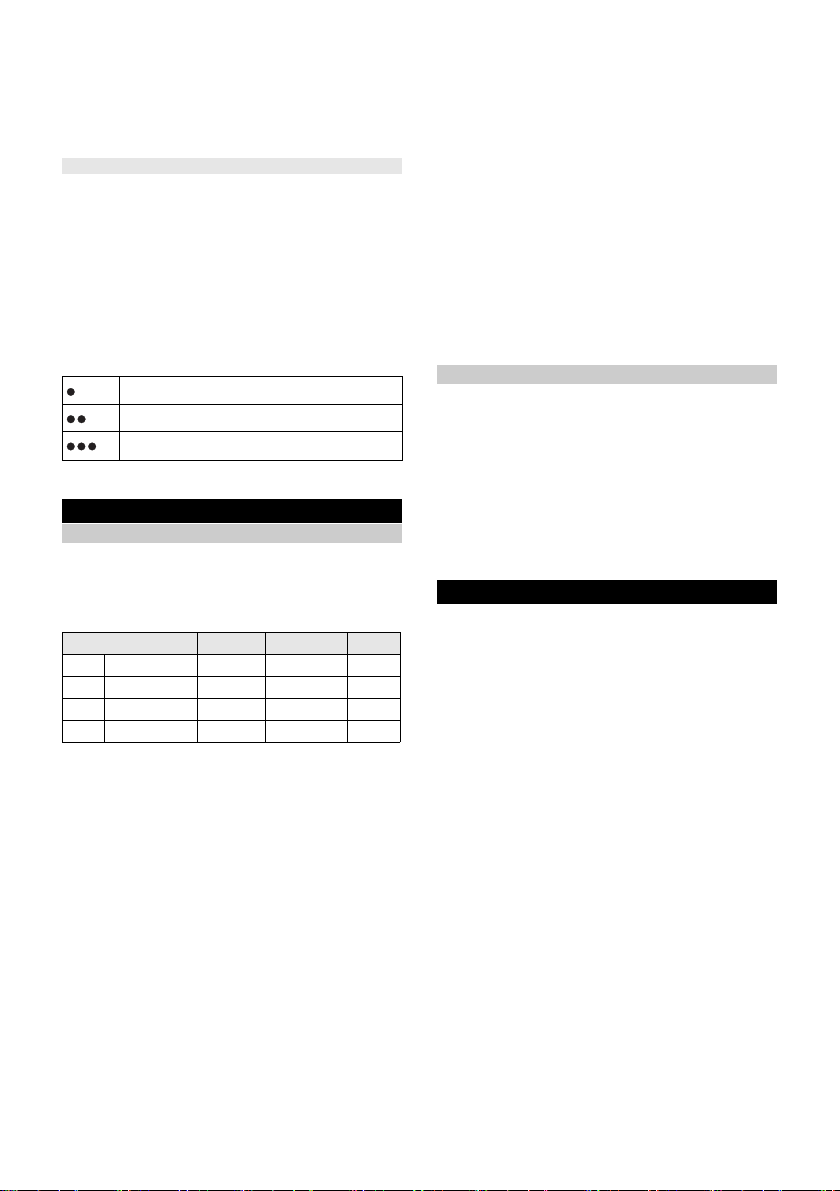

Hardness range °dH mmol/l TF

I soft 0-7 0-1.3 100

II Medium 7-14 1.3-2.5 90

III Hard 14-21 2.5-3.8 75

IV Very hard >21 >3.8 50

Loading ...

Loading ...

Loading ...