Loading ...

Loading ...

Loading ...

10

• In repetitive batch-processing applications, frequent cleaning

of the container will prolong the life of the blade assembly. In

no case should actual running time between cleanings exceed

one-half hour.

• Do not use container to store processed foods or beverages.

TO WASH AND RINSE CONTAINER

1. REMOVE CONTAINER FROM MOTOR BASE. Remove

lid. Rinse container interior and lid under running water.

Add washing solution to container. Scrub and ush out the

container interior and lid to dislodge and remove as much

food residue as possible. Empty container.

2. Wipe down exterior of container with a soft cloth or sponge

dampened with washing solution. Wash lid and lid insert

in fresh washing solution. Fill container one-quarter full

with fresh washing solution, cover (with lid only), place on

motor base and run on HI speed for two (2) minutes. Empty

container.

3. Repeat step 2 using clean rinse water in place of washing

solution.

IMPORTANT

NOTE: IN ORDER TO MINIMIZE POSSIBILITY OF SCALDING,

TEMPERATURE OF WASHING SOLUTION AND RINSE WATER

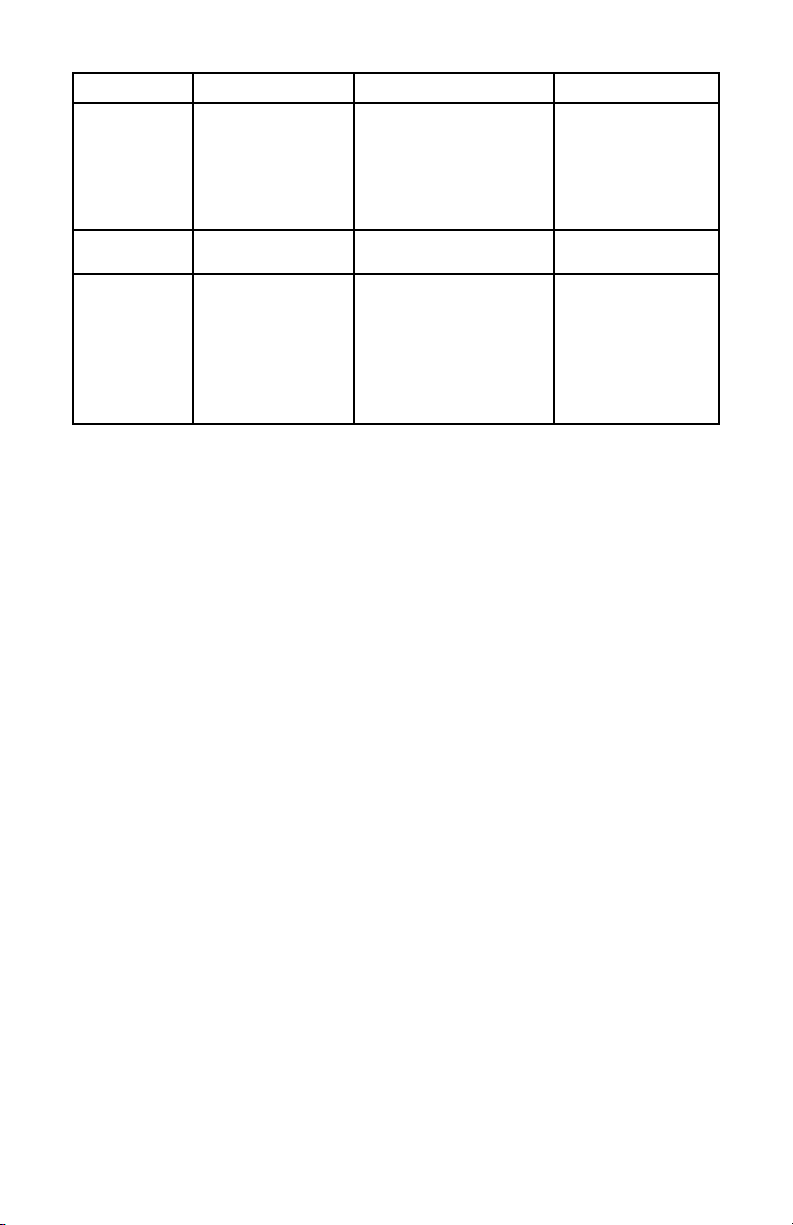

SOLUTION PRODUCT DILUTION IN WATER TEMPERATURE

Washing International

Products

Corporation LF2100

Liquid Low-Foam

Cleaner

1%–2%: 1¼ – 2¾

Ounce/Gallon (lower

dilution of 1% for normal

cleaning and up to 2% for

more stubborn soils)

Room

Temperature

Rinsing Plain Water Warm 95˚F (35˚C)

Sanitizing Clorox

®

Regular Bleach

(8.25% Hypochlorite

Concentration)

2 Teaspoons/Gallon

(Alternately a bleach

with 5.25% Hypochlorite

Concentration can be

used at dilution of 3

Teaspoons/Gallon)

Loading ...

Loading ...

Loading ...