Loading ...

Loading ...

Loading ...

F100 MEDIA AIR CLEANER

68-0239EF–2

5

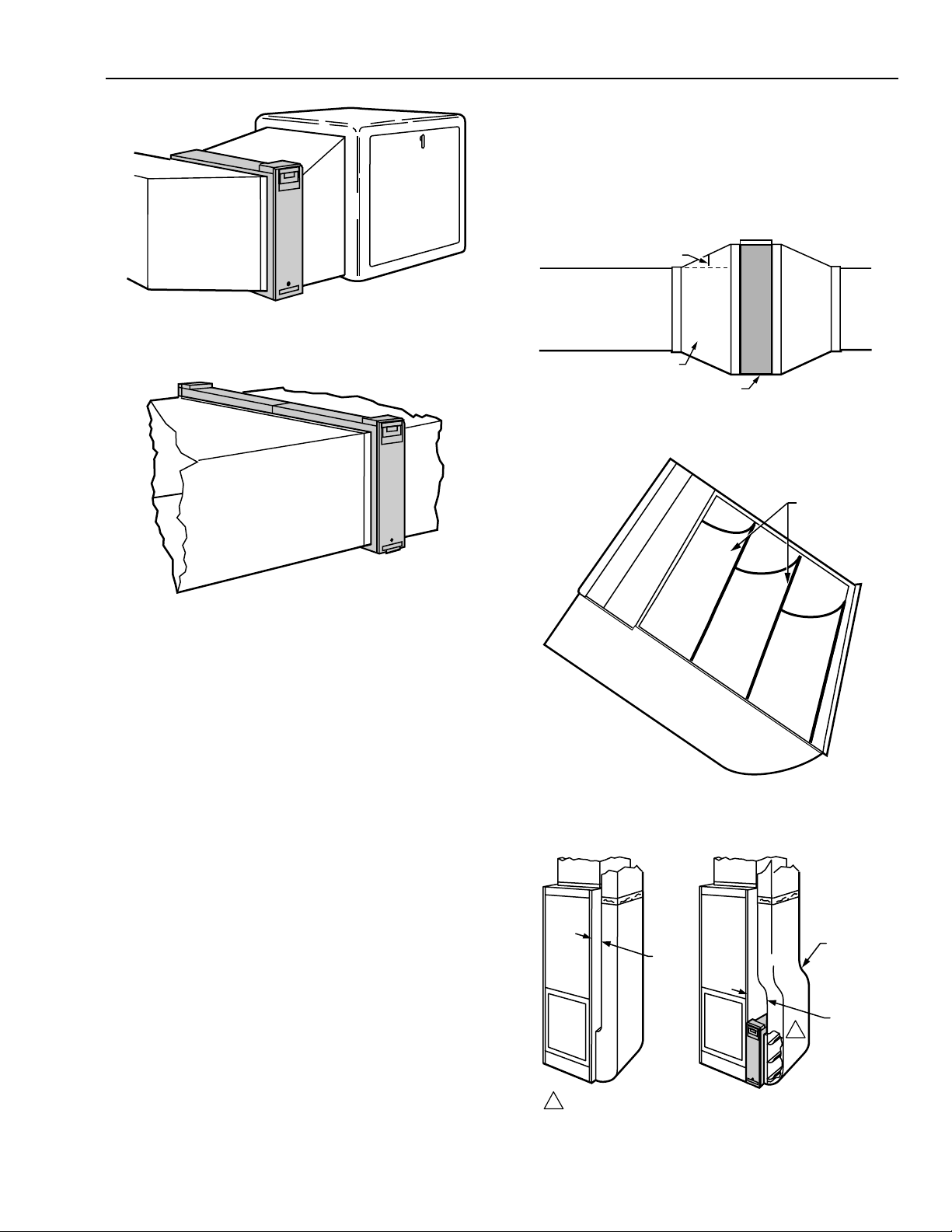

Fig. 9. Horizontal furnace, with media air filter mounted

vertically in return duct near furnace.

Fig. 10. Two or more media air cleaners used in a high

capacity system.

Determining Sheetmetal Requirements

The media air cleaner is adaptable to all new or existing

forced air heating and cooling systems used in residential

applications. Transitions or turning vanes may be required in

some applications for effective media air cleaner operation.

Transitions

Transitions are needed when the duct is a different size than

the media air cleaner cabinet. Follow these guidelines when

fabricating:

1. Use gradual transitions to reduce air turbulence and

increase efficiency. See Fig. 11.

2. Use no more than 20 degrees (about 4 in. per running

ft. (100 mm per 300 linear mm)) of expansion on each

side of a transition fitting.

Turning Vanes

If the media air cleaner is installed next to an elbow or angle

fitting, add turning vanes inside the angle to distribute airflow

more evenly across the face of the media. See Fig 12.

Offsets

If the duct connection to the furnace in a side installation

allows less than 7 in. (178 mm) for mounting media air

cleaner cabinet, attach an offset to the elbow. See Fig. 13.

Fig. 11. Duct size changed gradually to prevent

turbulence.

M945A

M946A

20 DEGREE EXPANSION PER SIDE PER

FITTING (4 IN. PER RUNNING FOOT

[100 MM PER 300 LINEAR MM])

RETURN AIR

DUCT

TRANSITION FITTING

MEDIA AIR CLEANER CABINET

M947B

DUCT SIZE CHANGED GRADUALLY TO PREVENT TURBULENCE.

M948A

LESS

THAN

7 in.

(178 mm)

OFFSET

AT LEAST

7 in.

(178 mm)

1

1 REQUIRED TURNING VANES HELP DISTRIBUTE AIRFLOW EVENLY.

TURNING

VANES

M565

1

Fig. 12. Turning vanes installed in bend help distribute

airflow evenly over face of media.

Fig. 13. Typical use of duct offset to make room for

media air cleaner.

Loading ...

Loading ...

Loading ...