Loading ...

Loading ...

Loading ...

25

ENGLISH

Main power

terminal block

Insulation sleeves

attachments

Fix firmly not

to be displaced

ODU-IDU

Communication cable

ODU-ODU

Communication cable

Main Power Connection Communication Connection

CAUTION

It should be wiring power cables or communication cables to avoid

interference with the oil level sensor. Otherwise, That oil level sensor

would be operated abnormally.

!

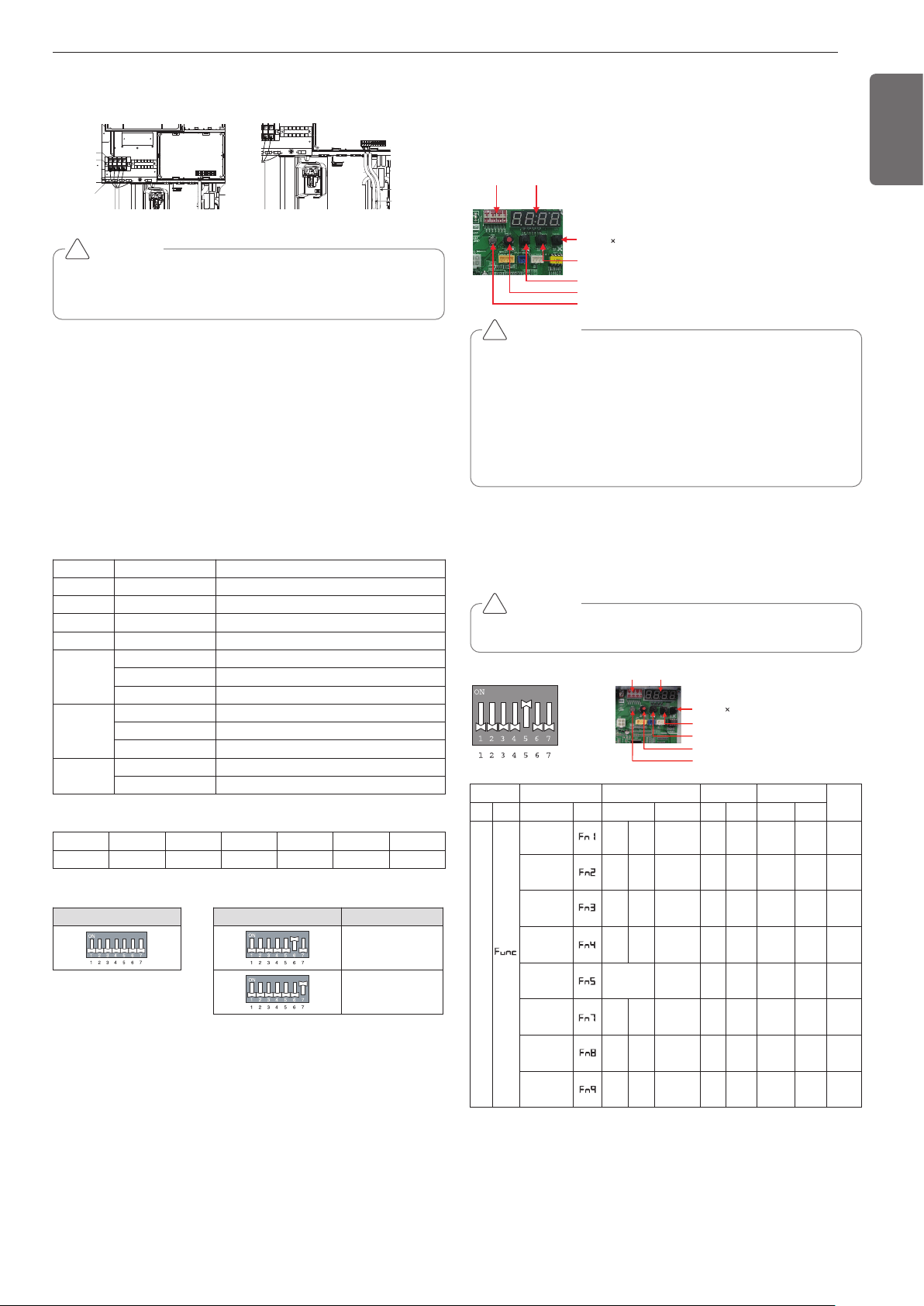

Checking the setting of outside units

Checking according to dip switch setting

- You can check the setting values of the Master outside unit from the

7 segment LED.

The dip switch setting should be changed when the power is OFF.

Checking the initial display

The number is sequentially appeared at the 7 segment in 5 seconds

after applying the power. This number represents the setting condition.

• Initial display order

• Master Unit • Slave Unit

Dip switch setting Dip switch setting ODU Setting

Slave 1

Slave 2

Order No Mean

①

8~20

Master model capacity(HP)

②

10~20

Slave 1 model capacity(HP)

③

10~20

Slave 2 model capacity(HP)

④

8~54

Total capacity(HP)

⑤

1 Cooling Only

2 Heat Pump

3 Heat Recovery

⑥

38 380V model

46 460V model

22 220V model

⑦

1 Full function

2 Core function

• Example) ARWN480DAS4

① ② ③ ④ ⑤ ⑥ ⑦

20 14 14 46 2 46 1

- After completing addressing, address of each indoor unit is indicated

on the wired remote control display window. (CH01, CH02,

CH03, ……, CH06 : Indicated as numbers of connected indoor units)

[MAIN PCB]

Automatic Addressing

The address of indoor units would be set by Automatic Addressing

- Wait for 3 minutes after supplying power.

(Master and Slave outside unit s, indoor units)

- Press RED button of the outside unit s for 5 seconds. (SW01C)

- A “88” is indicated on 7-segment LED of the outside unit PCB.

- For completing addressing, 2~7 minutes are required depending on

numbers of connected indoor units

-

Numbers of connected indoor units whose addressing is completed are

indicated for 30 seconds on 7-segment LED of the outside unit PCB.

DIP-SWITCH 7 - Segment

SW01C ( : confirm)

SW02C (ඔ : backward)

SW03C (ඖ : forward)

SW04C (

: cancel)

SW01D (reset)

CAUTION

• In replacement of the indoor unit PCB, always perform Automatic

addressing setting again (At that time, please check about using

Independent power module to any indoor unit.)

• If power supply is not applied to the indoor unit, operation error

occur.

• Automatic Addressing is only possible on the master Unit.

• Automatic Addressing has to be performed after 3 minutes to im-

prove communication.

!

Dip switch setting

Setting the function

Select the mode/function/option/value using ‘▶’, ‘◀’ Button and con-

firm that using the ‘●’ button after dip switch No.5 is turned on.

CAUTION

It is only executed when all indoor units are off.

!

DIP-SW01 7 - Segment

SW01C ( : confirm)

SW02C (ඔ : backward)

SW03C (ඖ : forward)

SW04C (

: cancel)

SW01D (reset)

* Functions save in EEPROM will be kept continuously, though the

system power was reset.

To cancel the function you need to set OFF.

Mode Function Option Value Action

Remarks

Content

Display1

Content

Display2

Content Display3

Content Display4

Implement Display5

In-

stal-

lation

Cool & Heat

Selector

oFF

op1~

op2

Selected

the option

- -

Change

the set

value

Blank

Save in

EEPROM

Geothermal

mode set-

ting

on

oFF

Selected

the option

- -

Change

the set

value

Blank

Save in

EEPROM

Sol. Valve

200 V out-

put

on

oFF

Selected

the option

- -

Change

the set

value

Blank

Save in

EEPROM

Variable

water flow

control

on

oFF

Selected

the option

- -

Change

the set

value

Blank

Save in

EEPROM

Outside unit

address

-

-

0~254

set

the

value

Change

the set

value

Blank

Save in

EEPROM

Target

pressure

adjusting

oFF

op1~

op4

Selected

the option

- -

Change

the set

value

Blank

Save in

EEPROM

Use Sump

Heater

on

oFF

Selected

the option

- -

Change

the set

value

Blank

Save in

EEPROM

IDU capacity

adjusting

on

oFF

Selected

the option

- -

Change

the set

value

Blank

Save in

EEPROM

Loading ...

Loading ...

Loading ...