Loading ...

Loading ...

Loading ...

9

Cybex Owner’s Manual

Qty Part Number Description Diagram

1 12000-560

Decal, Weight Plate

(30-290)

125

OWATONNA

MFG. APPR.

TECH. PUBS. APPR. DATE

DATE

REV.

DWG. NO.

SCALE

SIZE

CHECKED BY

DWG. BY

TITLE:

FINISH:

MATERIAL:

SHEET

OF

EXCEPT AS NOTED

GENERAL

TOLERANCES:

2 DECIMALS ± .03

3 DECIMALS ± .015

ANGLES ± 1°

FEATURES SHOWN

PERPENDICULAR OR

PARALLEL SHALL BE

SO WITHIN ± 1°

REMOVE ALL BURRS

BREAK SHARP EDGES

.005/.010 R

SURFACE FINISH

INDICATED PER

ANSI B46.1-1985

GENERAL

MACHINING

DIMENSIONS

IN INCHES

DATE

DATE

THIS NOTE REFERS TO ALL PLASTIC PARTS

AND ASSEMBLIES CONTAINING PLASTICS.

RAW MATERIAL AND COMPONENTS ON

SUB-ASSEMBLIES AND ASSEMBLIES MUST

COMPLY WITH EUROPEAN DIRECTIVE

RoHS 2002/95/EC.

REMOVE CARBURIZATION

AND SCALE FROM LASER

AND PLASMA CUT EDGES

12000-560

1:1

9/14/05

REL

DECAL, WT PLATE (30 - 290)

B

2 2

9/16/05

BB

NOTES:

1. RIGHT HAND SIDE - 40 POINT HELVETICA BOLD.

HORIZONTAL SCALE 80%.

TRACKING -50.

2. LEFT HAND SIDE - 48 POI NT FUTURA CONDENSED BOLD.

1 12000-561

Decal, Weight Plate

(310-490)

125

OWATONNA

MFG. APPR.

TECH. PUBS. APPR. DATE

DATE

REV.

DWG. NO.

SCALE

SIZE

CHECKED BY

DWG. BY

TITLE:

FINISH:

MATERIAL:

SHEET

OF

EXCEPT AS NOTED

GENERAL

TOLERANCES:

2 DECIMALS ± .03

3 DECIMALS ± .015

ANGLES ± 1°

FEATURES SHOWN

PERPENDICULAR OR

PARALLEL SHALL BE

SO WITHIN ± 1°

REMOVE ALL BURRS

BREAK SHARP EDGES

.005/.010 R

SURFACE FINISH

INDICATED PER

ANSI B46.1-1985

GENERAL

MACHINING

DIMENSIONS

IN INCHES

DATE

DATE

THIS NOTE REFERS TO ALL PLASTIC PARTS

AND ASSEMBLIES CONTAINING PLASTICS.

RAW MATERIAL AND COMPONENTS ON

SUB-ASSEMBLIES AND ASSEMBLIES MUST

COMPLY WITH EUROPEAN DIRECTIVE

RoHS 2002/95/EC.

REMOVE CARBURIZATION

AND SCALE FROM LASER

AND PLASMA CUT EDGES

12000-561

1:1

9/14/05

REL

DECAL, WT PLATE (310 - 490)

B

2 2

9/16/05

BB

.50

0

.750

1.016

2.032

3.048

4.064

5.080

6.096

7.112

8.128

9.144

1.47

1.69

Ø .406

3 PLCS

3.38

10.75

SPLIT BACKING

HERE

NOTES:

1. RIGHT HAND SIDE - 40 POINT HELVETICA BOLD.

HORIZONTAL SCALE 80%.

TRACKING -50.

2. LEFT HAND SIDE - 48 POI NT FUTURA CONDENSED BOLD.

19 4000C101 Weight Stack Plate

Move to desired location

1. Determine if you can move your machine through the required doorway(s).

2. If the machine ts through the doorway(s), move machine to desired location.

3. Attach rubber feet to each foot of the frame.

4. If weight stacks need to be installed follow procedure for installing weight stacks.

5. If the machine does not t through the doorway(s) follow door way procedures below.

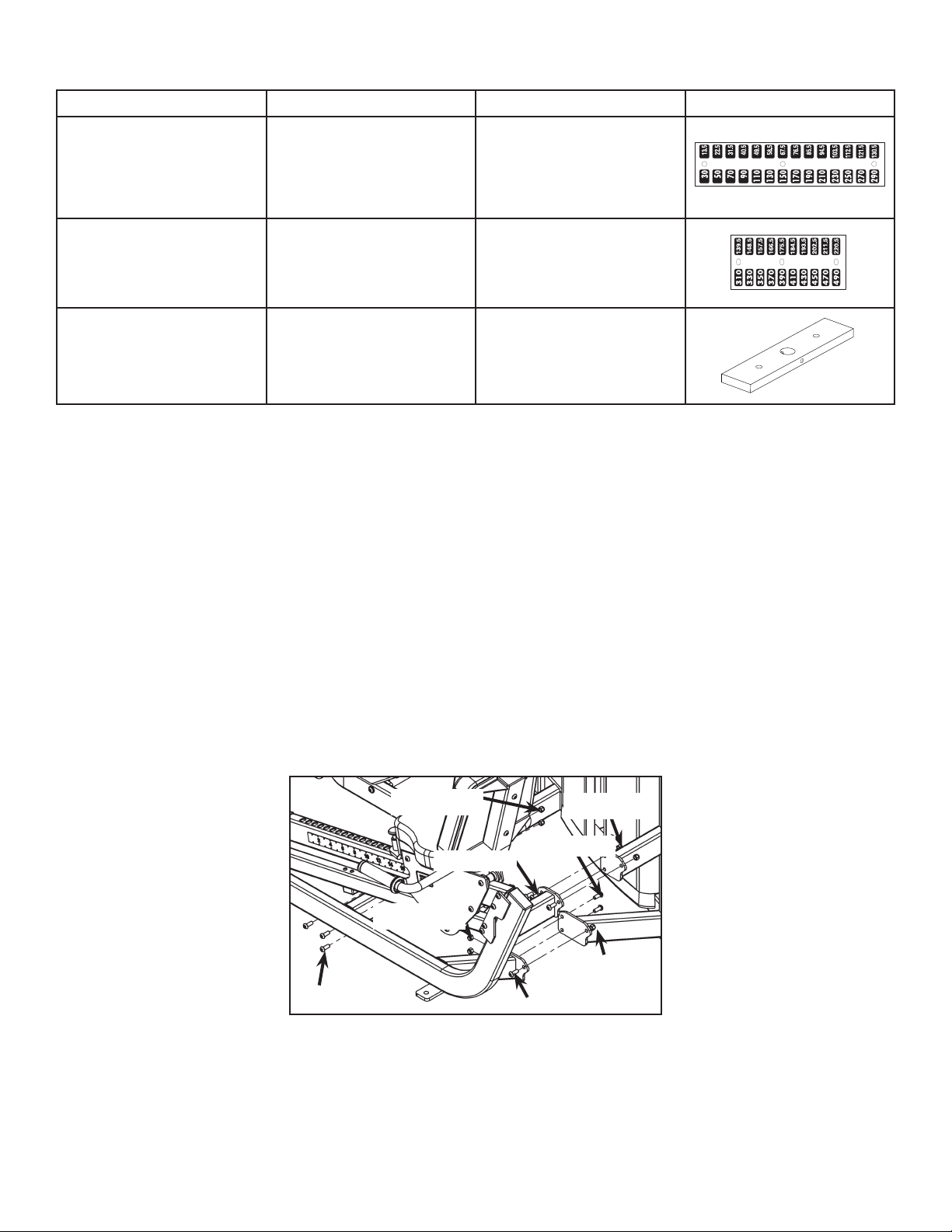

Doorway Instructions

1. Remove each (standard) cone-shaped shipping support using a 3/4” socket or wrench.

2. Remove the nine Button Head Socket Cap Screws (BHSCS) securing the two halves of the

frame.

BHSCS (3)

BHSCS (3)

Locknut (3)

Locknut (3)

BHSCS (2)

Locknut (2)

BHSCS (1)

Locknut (1)

3. Move each half through the doorway to the desired location.

Loading ...

Loading ...

Loading ...