Loading ...

Loading ...

Loading ...

22

FUMES DISCHARGE

EXTERNAL EXHAUST HOOD SUCTION

In this version the fumes and vapours are discharged outside

through the exhaust pipe.

To this end, the hood outlet fitting must be connected via a

pipe, to an external output.

The outlet pipe must have:

• a diameter not less than that of the hood fitting.

• a slight slope downwards (drop) in the horizontal sections to prevent conden-

sation from flowing back into the motor.

• the minimum required number of bends.

• the minimum required length to avoid vibrations and reduce the suction per-

formance of the hood.

You are required to insulate the pipes if it passes through cold environments.

In the presence of motors with 800m3/h or higher, a check valve is present to

prevent external air flowing back.

ASSEMBLY INSTRUCTIONS

Intended only for qualied personnel

The hood can be installed in various congurations.

The generic assembly steps apply to all installations; for each case,

follow the specic steps provided for the required installation.

OPERATION

WHEN TO TURN ON THE HOOD?

Switch on the hood at least one minute before starting to cook to direct

fumes and vapours towards the suction surface.

After cooking, leave the hood operating until complete extraction of all

vapours and odours. By means of the Timer function, it is possible to set

auto switch-o function which will allow the hood to turn o automatical-

ly after 15 minutes of operation.

WHICH SPEED IS TO BE SELECTED?

1st speed: maintains the circulation of clean air with low electricity consumption.

2nd speed: normal conditions of use.

3rd speed: presence of strong odours and vapours.

WHEN SHOULD THE FILTERS BE WASHED OR REPLACED?

The metal filters must be cleaned every 30 hours of operation.

For further details refer to the “MAINTENANCE” section.

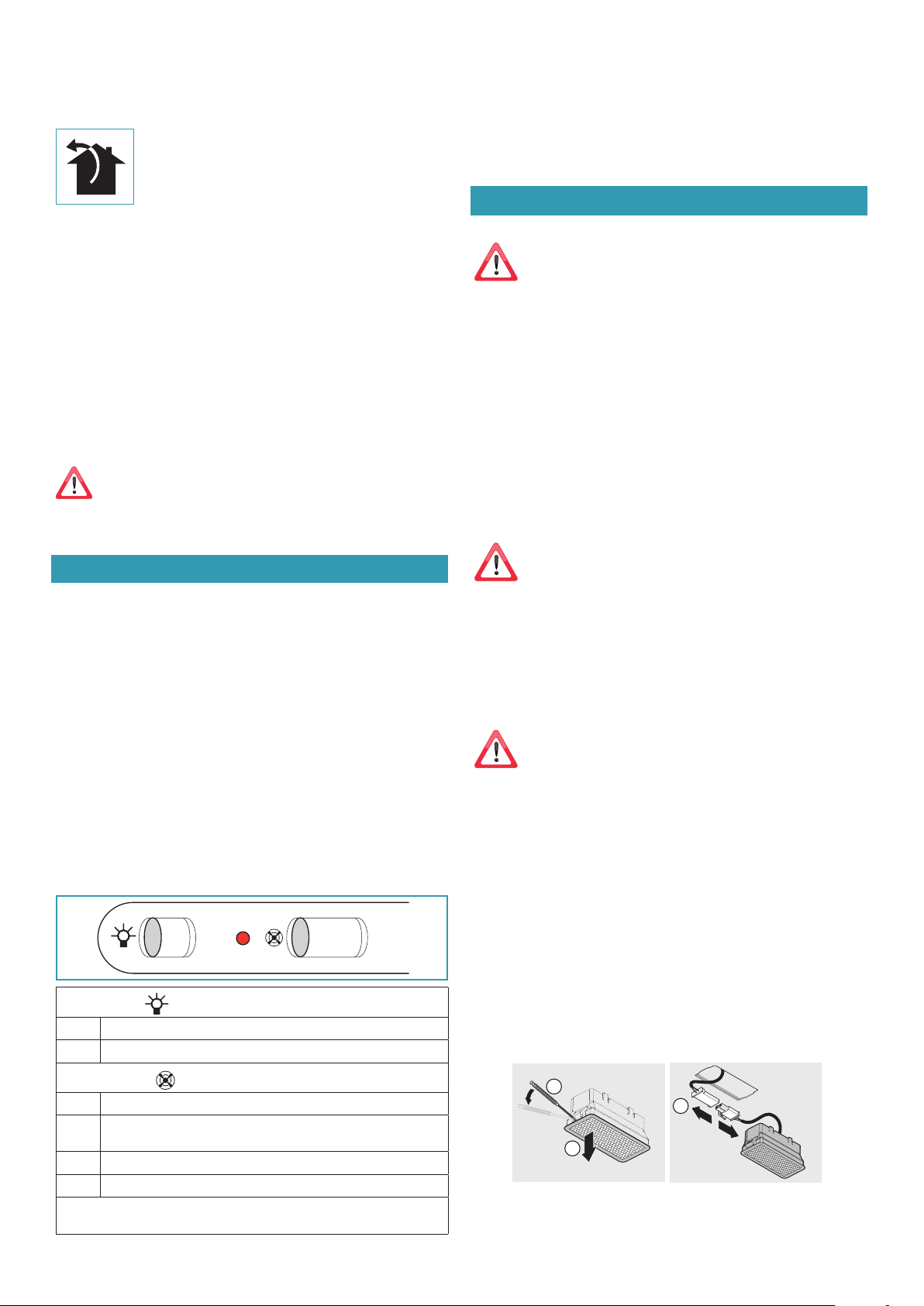

USE OF SLIDER

01 0123

LIGHT SWITCH

0

By placing the slider in position 0, the hood light is off

1

By placing the slider in position 1, the hood light is on

MOTOR SWITCH

0

By placing the slider in position 0, the hood motor is off

1

By placing the slider in position 1, the hood motor is set at minimum

speed

2

By placing the slider in position 2, the motor is set at medium speed

3

By placing the slider in position 3, the motor is set at high speed

The motor activation is signalled by the switching on of the red LED on the

slider

ONLY FOR HOODS WITH TWO MOTORS

There are two sliders in hoods equipped with double motor: each slider is asso-

ciated with a single motor.

As for lighting, in hoods with two spotlights a slider controls them both, while

the light switch of the other slider is inhibited; in the presence of three or more

spotlights, each slider controls a part of it.

MAINTENANCE

Before cleaning or carrying out maintenance operations, discon-

nect the equipment by removing the plug or switching o the

main switch. Do not use detergents containing abrasive, acidic

or corrosive substances or abrasive cloths.

Regular maintenance guarantees proper operation and performance over time.

Special attention is to be paid to the metal anti-grease lters : frequent clean-

ing of the filters and their supports ensures that no flammable grease is accu-

mulated.

CLEANING OF EXTERNAL SURFACES

You are advised to clean the external surfaces of the hood at least once every

15 days to prevent oily substances and grease from sticking to them. To clean

the brushed stainless steel hood, the Manufacturer recommends using "Magic

Steel" wipes.

Alternatively and for all the other types of surfaces, it can be cleaned using a

damp cloth, slightly moistened with mild, liquid detergent or denatured alcohol.

Complete cleaning by rinsing well and drying with soft cloths.

Do not use too much moisture or water around the push button

control panel and lighting devices in order to prevent humidity

from reaching electronic parts.

The glass panels can only be cleaned with specific, non-corrosive or non-abra-

sive detergents using a soft cloth.

The Manufacturer declines all responsibility for failure to comply with these in-

structions.

CLEANING OF INTERNAL SURFACES

Do not clean electrical parts, or parts related to the motor inside

the hood, with liquids or solvents.

For the internal metal parts, see the previous paragraph.

METAL ANTI-GREASE FILTERS

It is advised to frequently wash the metal filters (at least once a month) leav-

ing them to soak in boiling water and cleaning solution for 1 hour, taking care

not to bend them. Do not use corrosive, acid or alkaline detergents.

Rinse them well and wait for them to be completely dry before reassembling

them. Washing in a dishwasher is permitted, however, it may cause the filter ma-

terial to darken: to reduce the possibility of this problem from happening, use

low-temperature washes (131°F / 55°C max.).

To extract and insert the metal anti-grease filters see the assembly instructions.

LIGHTING

The range hood is equipped with high efficiency, low consumption LED spot-

lights with an extremely long life-span under normal use conditions.

Should the LED spotlight need to be replaced, proceed as shown in the figure.

12V

3

1

2

Loading ...

Loading ...

Loading ...