Loading ...

Loading ...

Loading ...

PH220-EU-EN V3.2 8/12

8

Electrode Maintenance and Troubleshooting

Most pH measurement difficulties are caused by the electrode. Careful handling and proper storage of

the electrode will increase measurement accuracy and electrode life.

Electrodes should be rinsed to remove all traces of storage solution, process medium, or previous test

solution.

Electrode Storage

The electrode should be stored in a soaker bottle or wetting cap filled with pH4 buffer. Never store

an electrode in distilled or deionized water as this will cause migration of the fill solution from the

electrode.

Electrode Cleaning

The type of electrode coating that occurs over time will determine the cleaning method. Soft

coatings can be removed by vigorous stirring or by using a squirt bottle. Organic chemical coating

(hard coatings) should be chemically removed. Only in extreme cases should the bulb be cleaned

mechanically.

Troubleshooting an Electrode

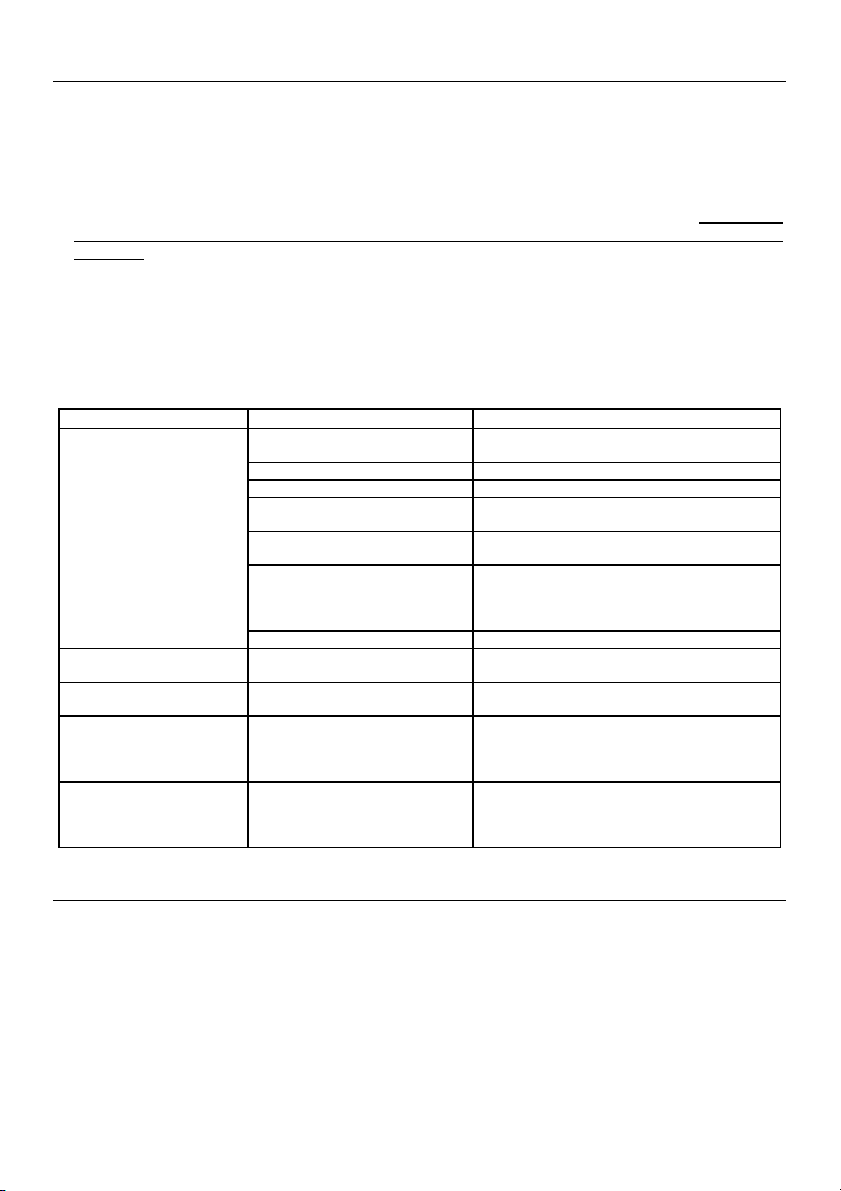

Symptom Cause Recommendation

Clogged Junction Soak in 4.07 M Potassium Chloride (KCl) @

60

o

C for 30 minutes.

Strong Alkaline measurement Soak in 0.1 M HCL overnight.

Deteriorated Gel layer Replace electrode.

Protein coating on electrode

surface

Soak in 1 gm Pepsin dissolved in 100ml of 0.1

m HCL for 30 minutes or as needed.

Oil, paint, dyes, suspended solids

etc. are on sensor

Rinse electrode alternately with a materials

solvent and a buffer 7.00.

Organic solvents are coating the

sensor

Organic mole fraction has to be less than 50%

to assure reasonable readings. Limit time of

measurement. Keep probe in the 7.0 buffer

between readings.

Long response time or

reading drift

Dehydrated membrane Read solution for dry bulb below:

Dry Bulb Long term storage without wetting Soak electrode tip in wetting cap filled with 1ml

7.00 buffer for 24 to 48 hours

Static Charge Wiping electrodes Rinse electrode in 7.0 buffer and blot. Do no

wipe electrode.

Same readings in different

buffers and samples

Cracked or broken bulb Replace electrode. Use bulb guard. Avoid

plunging electrode to bottom of container and

spinning bars. Wetting cap will protect bulb

between tests.

Erratic LCD display Samples have low ionic strength

(lacks salt); e.g. distilled, de-

ionized, boiled, lake water (high

pressure)

For each 50 ml of sample add 1 drop (50uL) of

SAT. KCl (No alteration in pH will occur using

inert KCl).

Calibration and Repair Services

Extech offers repair and calibration services for the products we sell. Extech also provides NIST

certification for most products. Call the Customer Service Department for information on calibration

services available for this product. Extech recommends that annual calibrations be performed to

verify meter performance and accuracy.

Copyright © 2012 Extech Instruments Corporation (a FLIR company)

All rights reserved including the right of reproduction in whole or in part in any form

ISO-9001 Certified

www.extech.com