Loading ...

Loading ...

Loading ...

18

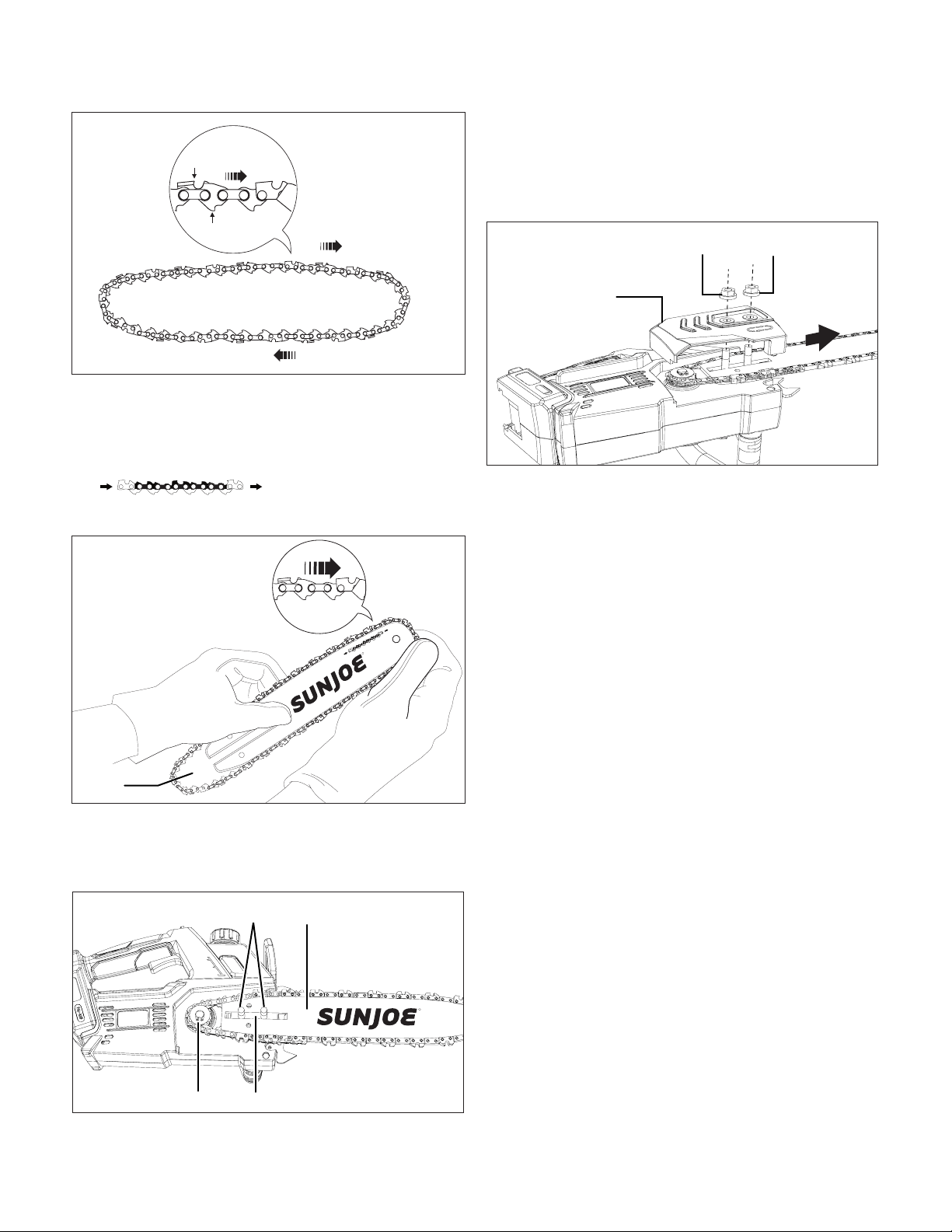

5. Starting at the tip, mount the chain drive links into the

bar groove, leaving a loop at the back of the bar. The

chain will loosely t until it is placed on the sprocket

(Fig. 19).

NOTE: Make certain of the direction of the chain

. If the chain is mounted

backwards, the saw will vibrate abnormally and will

not cut.

6. Mount the guide bar by inserting the studs into the long

slot on the guide bar; arrange the chain loop on the back

of the bar to ensure the sprocket is inserted in the loop

(Fig. 19).

7. Adjust the chain tension by pulling the guide bar + chain

forward, and make sure the chain is fully stretched. Using

your other hand, Fit the sprocket/chain end cover back

on by inserting the studs into the holes on the sprocket/

chain end cover. Replace the end cover nuts and screw to

tighten. (Fig. 20).

8. Lift up the guide bar tip slightly. Use the other end

of the hex key wrench/blade screwdriver to turn the

chain adjusting screw clockwise to tighten, turn it

counterclockwise to loosen (Fig.4).

NOTE: A new chain tends to stretch; check the chain

tension frequently, and adjust tension as required.

Chain Tension

Check the chain tension before using the saw when the chain

is cold. The correct tension of a cold chain is when there is no

slack on the underside of the guide bar; the chain is snug, but

you can rotate it by hand without binding.

During normal saw operation, the temperature of the chain

will increase. The drive links of a correctly tensioned warm

chain will hang approximately 0.050 in. (1.25 mm) out of the

bar groove (Fig. 21). Be aware that a chain tensioned while

warm, may be too tight upon cooling. Check the “cold tension”

before next use. The chain must be re-tensioned whenever the

ats on the drive links hang out of the bar groove (Fig. 21).

Fig. 17

Chain rotation

Sharp cutting edge

Chain drive link

R

Fig. 18

Loop

R

Fig. 19

Guide bar

Sprocket

Studs

Slot

Fig. 20

Sprocket/chain

end cover

End cover nuts

Pulling

forward

Loading ...

Loading ...

Loading ...