Loading ...

Loading ...

Loading ...

24

CHECKING THE GAS SUPPLY

1. Check the manometer zero point is correct.

2. Connect the manometer to the cooktop pressure

point. This is located on the regulator.

3. Turn on the gas supply and electricity and try to

ignite the gas.

NOTE! It will take additional time to light the gas for the

first time as air needs to be purged from the pipes.

4. With the appliance operating check the outlet pressure

• whenallburnersoftheapplianceareoperating

atmaximum,

• whenthesmallestburneroftheapplianceis

operating at minimum.

Under these conditions the outlet pressure should not

vary from the nominal outlet pressure of 1.00kPa by

more than

±

0.20kPa.

Iftheregulatorappearstonotbeperformingsatisfactorily,

then check the following points:

1. If the outlet pressure is consistently too low then the

inlet pressure may be too low and adjustment of an

upstreamregulatormaybeneeded,oranupstream

regulatororvalvewithinsufcientowcapacitymay

be present in the gas supply line. If this is suspected

then it may be necessary to repeat the checks whilst

measuring both the inlet and outlet pressure to

determine if the inlet pressure is in the range

1.13 – 5kPa.

2. Checkthattheregulatorhasbeenttedtothegas

supplylineinthecorrectorientation,thearrowonthe

base of the body indicates the direction of gas flow.

Oncethesecheckshavebeencompleted,ifthe

regulator still fails to perform in a satisfactory manner it

should be replaced.

LP Conversion – Important

This appliance is fitted with Natural Gas

burner injectors.

Please follow the procedure below if a conversion to suit

LP gas is required.

The conversion kit contains appropriate LPG injectors

and 1 LPG sticker.

1. Remove the hotplate burners to access the hotplate

injectors.ReplacethefactoryttedNGinjectorswith

theappropriateinjectors,assupplied(seeTable3).

Table 3

burner type

natural gas (nominal test point pressure: 1.00kPa) LPG (nominal test point pressure: 2.60kPa)

injector size (mm) gas consumption (MJ/h) injector size (mm) gas consumption (MJ/h)

Small burner 1.00 5.1 0.55 4.2

Medium burner 1.35 9.0 0.70 6.5

Large burner 1.60 12.1 0.90 10.7

Wok burner 0.85 + 2 x 1.25 17.0 0.46 + 2 x 0.73 17.0

OPERATION ON N.G./S.N.G.

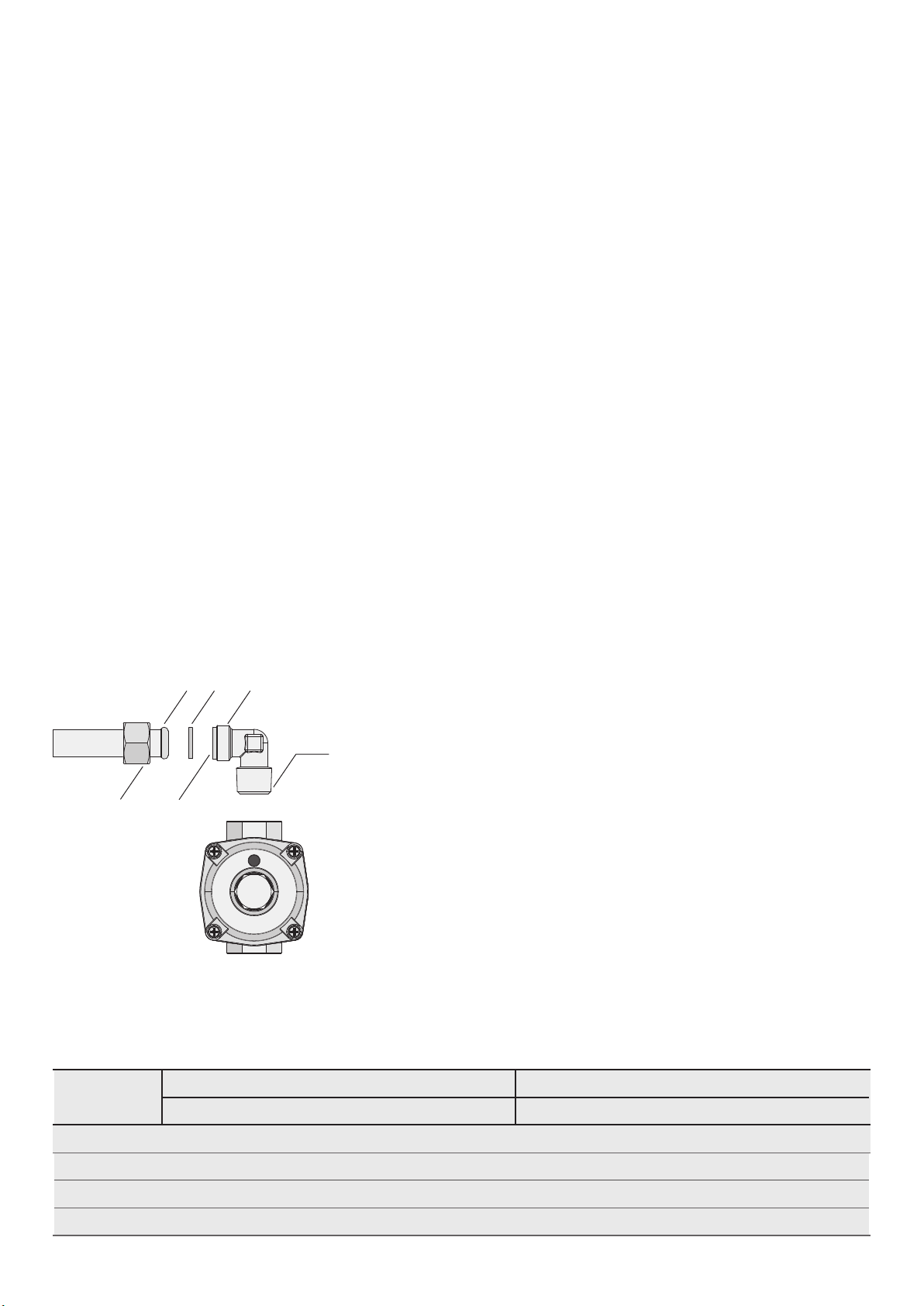

Assembly of Regulator

The assembly of the regulator to the cooktop manifold

is achieved via the elbow union and sealing washer

supplied,refertogure9.

The½”parallelthreadconnectstothemanifold,andthe

sealing washer is placed between the manifold end and

the flat face on the elbow.

The ½” tapered thread connects to the outlet of

theregulator,andissealedonthethreadusing

approved thread sealing tape or approved thread

sealing compound.

The inlet of the regulator is a ½” parallel thread and

is connected to consumer piping or hose assembly.

Regulatorsaresuppliedpre-adjustedandcongured

by the component maker for use with Natural Gas.

The appliance installer is not required to make an

adjustment to obtain the correct outlet pressure setting.

An arrow on the base of the regulator indicates the

direction of gas flow when the inlet and outlet of the

regulator is orientated correctly. When the regulator has

beenttedcheckforleaksfromtheconnectionswith

soapy water.

Figure 9

½” Tapered thread

Seal using approved

sealing tape or

approved thread

sealing compound

Manifold

endform

Female nut Flat face

Sealing

washer

½” Parallel

thread

Regulator

Outlet

Inlet

Loading ...

Loading ...

Loading ...