Loading ...

Loading ...

Loading ...

6

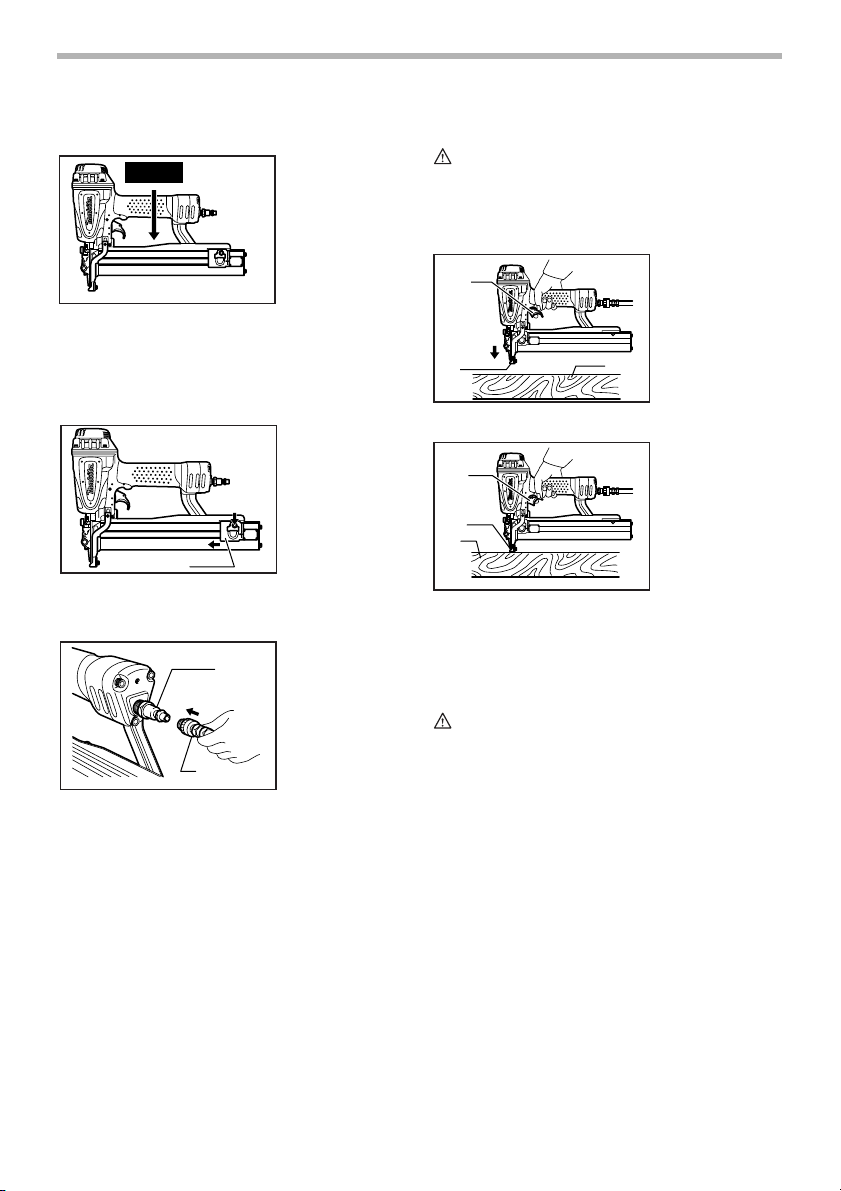

2. Insert strip of staples into the magazine. Two strips

of staples can be loaded.

3. Depress the lock pin lightly and pull the pusher to

unhook it.

With the lock pin depressed, return the pusher

slowly and gently to the original position.

Keep depressing the pusher until it passes through.

Connecting air hose

Slip the air socket of the air hose onto the air fitting on the

stapler. Be sure that the air socket locks firmly into posi-

tion when installed onto the air fitting. A hose coupling

must be installed on or near the tool in such a way that

the pressure reservoir will discharge at the time the air

supply coupling is disconnected.

OPERATION

CAUTION:

• Make sure all safety systems are in working order

before operation.

1. Pull the trigger first and then place the contact ele-

ment against the workpiece.

2. To drive a staple, you may place the contact ele-

ment against the workpiece and pull the trigger, or

No. 1 method is for continuous stapling.

No. 2 method is for intermittent stapling, when you wish

to drive a staple carefully and very accurately.

CAUTION:

• However when the tool is set to the “Intermittent

Staplling” mode, WITH THE TRIGGER HELD IN A

HALF-PULLED POSITION, an unexpected stapling

could occur, if contact element is allowed to re-con-

tact against the workpiece or the other surface

under the influence of recoil.

In order to avoid this unexpected stapling, perform

as follows;

A. Do not place the contact element against the work-

piece with excessive force.

B. Pull the trigger fully and hold it on for 1-2 seconds after

stapling.

For No. 2 method, the OPTIONAL SEQUENTIAL TRIP

TRIGGER (SINGLE SHOT PART) is used . Replace the

trigger part with this.

1. Pusher

1. Air fitting

2. Air socket

007212

1

007213

1

2

007197

1. Trigger

2. Contact element

3. Workpiece

1. Trigger

2. Contact element

3. Workpiece

1

2

3

007199

1

2

3

007198

Loading ...

Loading ...

Loading ...