Loading ...

Loading ...

Loading ...

NON-CANADIAN ELECTRICLaundry Center

1. Remove the screw securing the

terminal block access cover to the

rear panel and remove cover.

2. Install a U.L approved strain relief

connector in the entry hole on the

back panel.

J

3. Remove the neutral ground wire from the green ground

screw located above the termial block.

INSTALLATION

Run some water from the hot and cold faucets to flush the

water lines and remove particles that might clog up the

water valve screens.

.

3.

Check inlet hoses to ensure the rubber washers are installed

in each end.

Carefully connect the inlet hoses to the water valve (on the

left sideof the washer cabinet), tighten byhand, then tighten

another 2/3 turn with pliers.

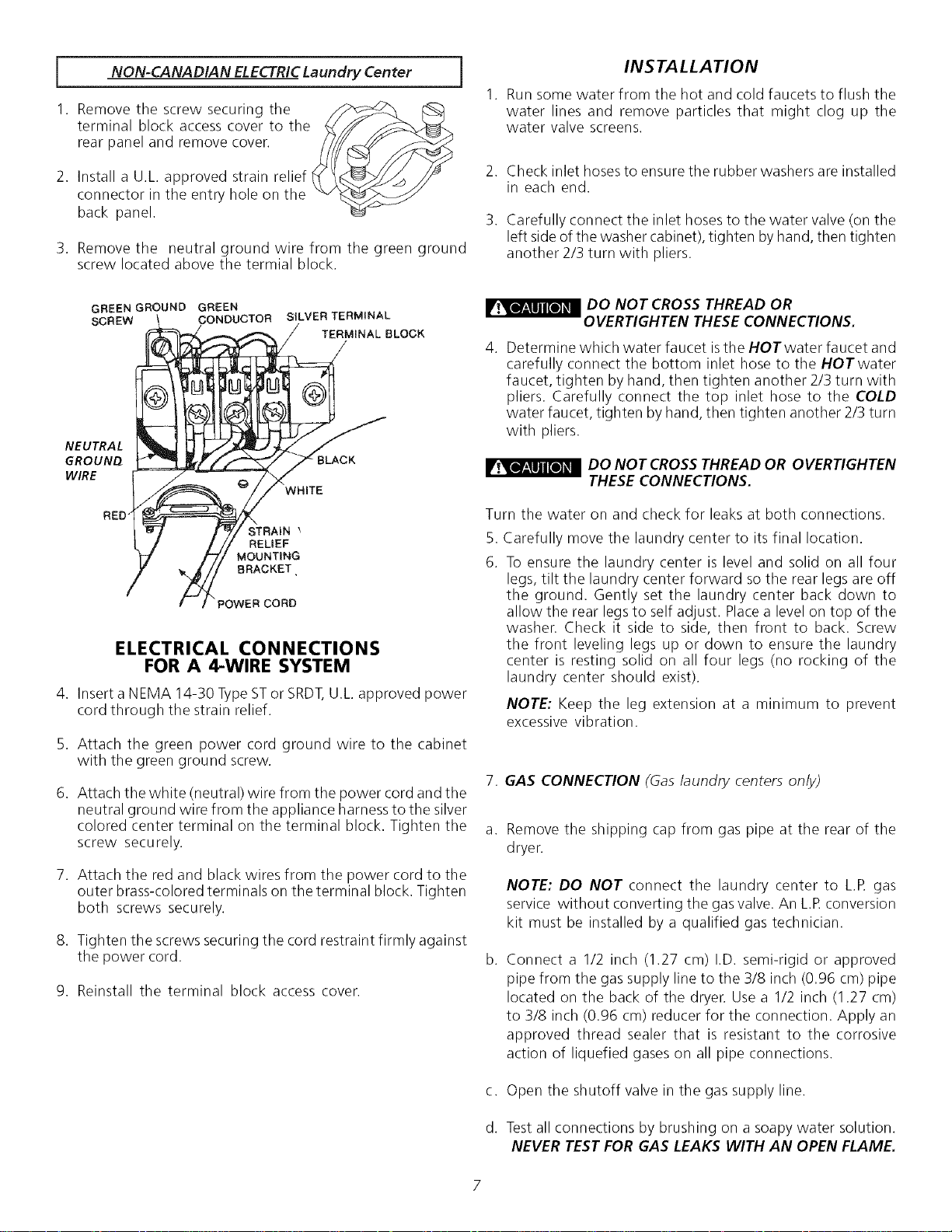

GREEN GROUND GREEN

SCREW CONDUCTOR SILVER TERMINAL

TERMINAL BLOCK

NEUTRAL

GROUNQ

WIRE

BLACK

WHITE

STRAIN

RELIEF

MOUNTING

BRACKET,

POWER CORD

ELECTRICAL CONNECTIONS

FOR A 4-WIRE SYSTEM

4. Insert a NEMA 14-30 TypeSTor SRDT,U.L approved power

cord through the strain relief.

5. Attach the green power cord ground wire to the cabinet

with the green ground screw.

6. Attach the white (neutral) wire from the power cord and the

neutral ground wire from the appliance harnessto the silver

colored center terminal on the terminal block. Tighten the

screw securely.

7. Attach the red and black wires from the power cord to the

outer brass-colored terminals on the terminal block. Tighten

both screws securely.

8. Tighten the screws securing the cord restraint firmly against

the power cord.

9. Reinstall the terminal block access cover.

_ DO NOT CROSS THREAD OR

OVERTIGHTEN THESE CONNECTIONS.

4. Determine which water faucet isthe HOTwater faucet and

carefully connect the bottom inlet hose to the HOTwater

faucet, tighten by hand, then tighten another 2/3 turn with

pliers. Carefully connect the top inlet hose to the COLD

water faucet, tighten by hand, then tighten another 2/3 turn

with pliers.

DO NOT CROSS THREAD OR OVERTIGHTEN

THESE CONNECTIONS.

Turn the water on and check for leaks at both connections.

.

6.

Carefully move the laundry center to its final location.

To ensure the laundry center is level and solid on all four

legs, tilt the laundry center forward so the rear legs are off

the ground. Gently set the laundry center back down to

allow the rear legs to self adjust. Placea level on top of the

washer. Check it side to side, then front to back. Screw

the front leveling legs up or down to ensure the laundry

center is resting solid on all four legs (no rocking of the

laundry center should exist).

NOTE: Keep the leg extension at a minimum to prevent

excessive vibration.

7. GAS CONNECTION (Gas laundry centers only)

a.

b.

c.

d.

Remove the shipping cap from gas pipe at the rear of the

dryer.

NOTE: DO NOT connect the laundry center to L.R gas

service without converting the gas valve. An LR conversion

kit must be installed by a qualified gas technician.

Connect a 1/2 inch (1.27 cm) I.D. semi-rigid or approved

pipe from the gas supply line to the 3/8 inch (0.96 cm) pipe

located on the back of the dryer. Use a 1/2 inch (1.27 cm)

to 3/8 inch (0.96 cm) reducer for the connection. Apply an

approved thread sealer that is resistant to the corrosive

action of liquefied gases on all pipe connections.

Open the shutoff valve in the gas supply line.

Test all connections by brushing on a soapy water solution.

NEVER TEST FOR GAS LEAKS WITH AN OPEN FLAME.

Loading ...

Loading ...

Loading ...