Loading ...

Loading ...

Loading ...

The term ″ power tool ″ in the warnings refers to your mains-operated (corded) power tools or

battery-operated (cordless) power tools.

The term residual current device (RCD) may be replaced by the term ground fault

circuit interrupter (GFCI) or earth leakage circuit breaker (ELCB)

Do not operate power tools in explosive atmospheres, such as in the pres- ence of flammable

Keep children and bystanders away while operating a power tool. Distrac- tions can cause you

Power tool plugs must match the outlet. Never modify the plug in any way. Do not use any

adapter plugs with grounded power tools. Unmodified plugs and match- ing outlets will reduce

Avoid body contact with grounded surfaces such as pipes, radia- tors, ranges and refrigerators.

Do not expose power tools to rain or wet conditions. Water entering a power tool will increase

Do not abuse the cord. Never use the cord for carrying, pulling or unplug- ging the power tool.

Keep cord away from heat, oil, sharp edges or moving parts. Damaged or entangled cords

When operating a power tool outdoors, use an extension cord suit- able for outdoor use. Use

of a cord suitable for outdoor use reduces the risk of elec- tric shock.

If operating a power tool in a damp location is unavoidable, use a residual current device

(RCD) protected supply.Use of a RCD reduces the risk of elec- tric shock.

Stay alert, watch what you are doing and use common sense when operating a power tool. Do

dust mask, non-skid safety shoes, hard hat, or hearing protec- tion used for appropriate condi-

Prevent unintentional starting. Ensure the switch is in the off-position before connecting to

Do not overreach. Keep proper footing and balance at all times. This enables better control of

the power tool in unexpected situations.

Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing and gloves

away from moving parts. Loose clothes, jewellery or long hair can be caught in moving parts.

If devices are provided for the connection of dust extraction and collection facili- ties, ensure

these are connected and properly used. Use of dust collection can reduce dust-related

Do not force the power tool. Use the correct power tool for your application. The correct power

tool will do the job better and safer at the rate for which it was de- signed.

Do not use the power tool if the switch does not turn it on and off. Any power tool that cannot

Disconnect the plug from the power source and/or the battery pack from the power tool before

Store idle power tools out of the reach of children and do not allow persons unfa- miliar with

Maintain power tools. Check for misalignment or binding of moving parts, break- age of parts

and any other condition that may affect the power tools operation. If damaged, have the power

DANGER: Keep hands away from cutting area and blade. Keep your second hand on auxiliary

handle or motor housing. If both hands are holding the saw, they cannot be cut by the Original

Do not reach underneath the workpiece. The guard cannot protect you from the blade below

Adjust the cutting depth to the thickness of the workpiece. Less than a full tooth of the blade

Never hold piece being cut in your hands or across your leg. Secure the work- piece to a stable

platform. It is important to support the work properly to minimize body exposure, blade binding,

exposed metal parts of the power tool “live” and shock the operator.

When ripping always use a rip fence or straight edge guide. This improvesthe accuracy of cut

Always use blades with correct size and shape (diamond versus round) of arbor holes. Blades

that do not match the mounting hardware of the saw will run eccen- tri- cally, causing loss of

Kickback is a sudden reaction to a pinched, bound or misaligned saw blade, caus- ing an

uncontrolled saw to lift up and out of the workpiece toward the opera- tor;

When the blade is pinched or bound tightly by the kerf closing down, the blade stalls and the

motor reaction drives the unit rapidly back toward the operator;

If the blade becomes twisted or misaligned in the cut, the teeth at the back edge of the blade

When blade is binding, or when interrupting a cut for any reason, release the trigger and hold

the saw motionless in the material until the blade comes to a com- plete stop. Never attempt to

remove the saw from the work or pull the saw back- ward while the blade is in motion or

When restarting a saw in the work-piece, centre the saw blade in the kerf and check that saw

Do not use dull or damaged blades. Unsharpened or improperly set blades pro- duce narrow

kerf causing excessive friction, blade binding and kickback.

Blade depth and bevel adjusting locking levers must be tight and secure before making cut. If

Use extra caution when sawing into existing walls or other blind areas. The protruding blade

Check lower guard for proper closing before each use. Do not operate the saw if lower guard

position. If saw is accidentally dropped, lower guard may be bent. Raise the lower guard with

Check the operation of the lower guard spring. If the guard and the spring are not operating

properly, they must be serviced before use. Lower guard may operate sluggishly due to

damaged parts, gummy deposits, or a build-up of debris.

is in its path. Be aware of the time it takes for the blade to stop after switch is released.

their meanings. Proper interpretation of these sym- bols will allow for more efficient and safer

Before any work on the machine itself, keep the mains plug out of the supply.

To avoid accidental starting, make sure Lock-Off button is not engaged prior to plugging in tool

Press the lock button (19) and keep it pressed.

The The spindle lock button (19) may be actuated only when the saw spindle is at a standstill.

Otherwise, the power tool can be damaged.

With the allen wrench (9), unscrew the bolt (13) turning in rotation direction.

Tilt back the retracting blade guard (2) and hold firmly.

Remove the clamping flange (13) and the saw blade (1) from the ma- chine.

Clean the saw blade (1) and all clamping parts to be assembled. b.Tilt back the retracting blade

guard (2) and hold firmly.

Place the saw blade (1) on to the mounting bolt (13). The cutting direc- tion of the teeth (direc-

tion or arrow on saw blade) and the direction-of-rota- tion arrow on the blade guard (2) must

Mount the blot & screw (13) in turning in rotation direction. e.Press the spindle lock button (19)

Observe correct main voltage! The voltage of the power source must agree with

the voltage specified on the nameplate of the ma- chine.

Before engage the ON/OFF switch (15), check that the saw blade is prop- erly fitted and run

To start the machine, press the ON/OFF switch (15) and keep it pressed. To stop the machine,

release the ON/OFF switch (15) or when it is locked with the lock-off button (14), briefly press the

ON/OFF switch (15) and then release it.

Do not stare directly at the laser beam, do not deliberately aim the beam at

person- nel and ensure that it is not directed towards the eye of a person for longer than 0.25s.

When you make the line of the cut on the work piece, the laser can help you get better alignment.

With the allen wrench( ) (13)turning in rota- tion direction.

Insert the rip guide (7) through all three slots on the base plate (3) at the front of the saw,

Slide the left guide (7) through the slots until it extends out the right side of the base plate(3).

Adjust the rip guide for the desired width of cut and then securely tighten the rip guide locking screw (12).

Connect the small end of the vacuum adap- tor (8)

to the dust extraction port (5) on the tool.

Connect the other end of the vacuum adap-

tor(8) to the end of a vacuum hose.

Cutting Methods Parallel Cut Adjustment

a.

b.

d.

Pocket Cuts

A pocket cut is a cut that must be made inside the area of the work-piece rather than starting from

an outside edge and working inward. Pocket cuts can be very danger- ous for the novice to

attempt because of the need to manually retract the lower guard and perform a plunge cut which

is potential hazardous.

a.

b.

c.

d.

WARNING:Always cut in a forward direction when pocket cutting. Cutting in the reverse

direction could cause the saw to climb up on the work-piece and back toward you.

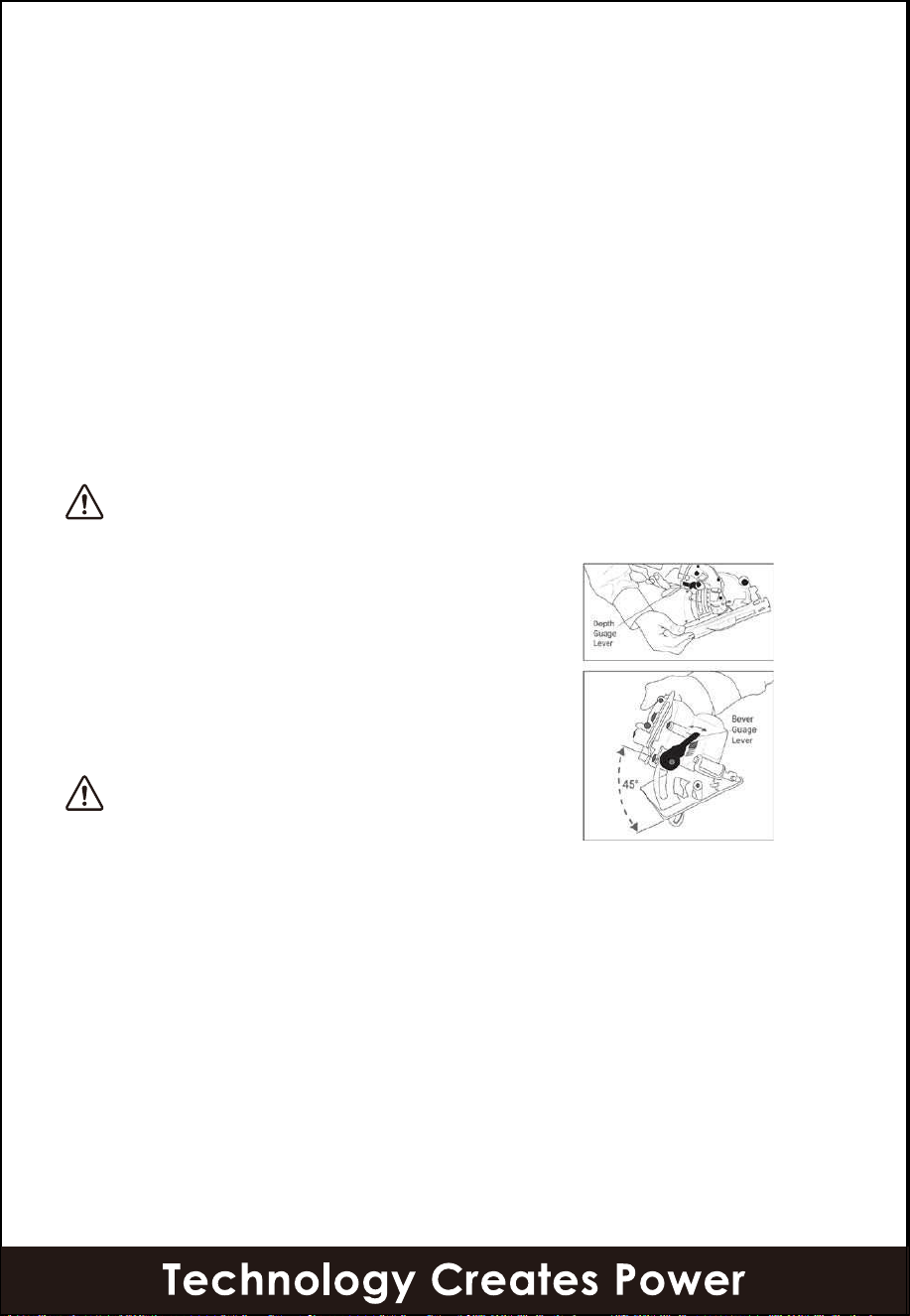

Depth Adjustment

a.

b.

c.

ATTENTION : Always maintain the correct blade depth

setting. For all cuts the blade depth should not exceed 1/4”

below the material being cut. Excessive blade depth increases

the chance of saw KICKBACK.

Angle Adjustment

a.

b.

9.

Never use aggressive detergents or solvents for cleaning.

a.

b.

Loosen the lock knob of edge guide.

Slide the edge guide through the slots in the shoe to the desired width. c.Tighten the lock bolt

to secure it in the position.

Ensure that the edge guide rests against the wood along its entire length to give a consistent

parallel cuts.

Hold the lower blade guard by the handle.

Rest the front of the base flat against the work-piece with the rear handle related so the blade

does not touch the work-piece.

Start the saw and let the blade reach full speed.

Guide the saw down into the work-piece and make the cut.

Unplug your circular saw.

Loosen the depth clamp lever (17)on the depth guide

at the back of saw.

Hold the base plate (3) against the edge of the work piece

and lift the body of the saw until the blade is at the right

depth determined by the depth gauge (align the scale

line). d.Secure the base plate(3) by tightening the lever(17).

Loosen the bevel scale bracket (10) for angle adjustment.

Adjust the base plate(3) to the desired angle between 0°to45° Tighten the bevel scale brack-

et(10).

Maintenance

To prevent accidents, always unplug the saw from the power source before cleaning or

performing any maintenance the saw may be cleaned most effectively using compressed

air.Always wear safety goggles when using compressed air. If compressed air is not available,

use a brush to remove dust and chips from the saw.

Motor ventilation vents and switch levers must be kept clean and free of foreign matter. Do not

Do not use cleaning agents to clean the plastic parts of the tool. A mild detergent

on a damp cloth is recommended. Water must never come into contact with the tool.

Turn the motor off and disconnect the mains plug. While transporting, be careful not to drop, or

shock the machine. For transport, the machine has to be fixed against slipping and tipping over.

Do not place objects on the machine.

This device complies with part 15 of the FCC rules. Operation is subject to the following two

conditions: (1) This device may not cause harmful interference, and (2) this device must accept

attempt to clean by inserting pointed objects through open- ings.

Never use any caustic agents to clean plastic parts. Such as: gasoline, carbon tetrachloride,

chlorinated cleaning solvents, ammonia and household cleaners containing ammonia. Do not

Have an authorized service center examine and/or replace the worn carbon brushes in the

event of excessive parking.

Blades become dull even when cutting regular lumber, a sure sign of a dull blade is the need

If you discover any damage, consult the exploded drawing and parts list to de- termine exactly

Clean the housing only with a damp cloth. Do not use any solvents! Dry thor- oughly

If the supply cord of this power tool is damaged, it must be replaced by a similar cord available

through the service organization or a qualified authoritative techni- cian.

- 07 -

Loading ...