Loading ...

Loading ...

Loading ...

18

EXHAUST PORT AND SILENCER

Depending on the type of fuel used,the type and amount of oil used,and/or your operating conditions,the

exhaust port and silencer may become blocked with carbon deposits.Ifyou notice a power loss with your

petrol powered tool. A qualified service technician will need to remove these deposits to restore

performance.

ADJUSTING CARBURETOR

NOTE: Do not adjust carburetor unless necessary. If you have trouble with the carburetor, see your

dealer. Improper adjustment may cause engine damage and void warranty.

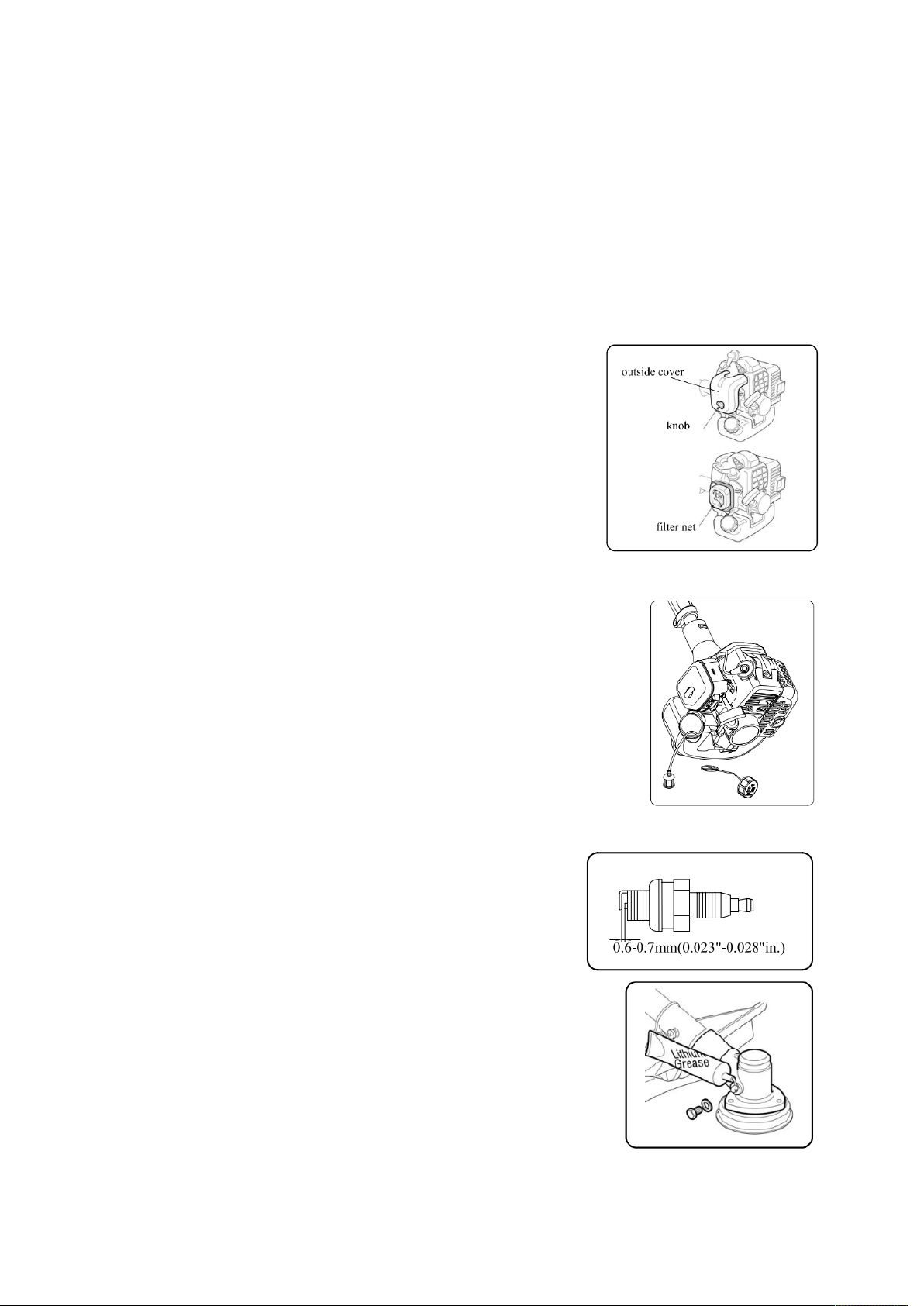

AIR FILTER

Accumulated dust in the air filter will reduce engine efficiency.

Increase fuel consumption and allow abrasive particles to pass into

the engine. Remove the air filter as often as necessary to maintain

in a clean condition.

Light surface dust can readily be removed by tapping the filter.

Heavy deposits should be washed out in suitable solvent.

Remove filter cover by loosening air filter cover knob (See fig.20).

FUEL FILTER

Fuel tank is fitted with a filter.Filter is situated at the free end of fuel pipe

and can be picked out through fuel port with a piece of hooked wire or the

Like (See fig.21).

Check the fuel filter periodically. Do not allow dust to enter into fuel

tank.Clogged filter will cause difficulty in starting engine or

abnormalities in engine performance.

When filter is dirty, replace the filter.

When the inside of the fuel tank is dirty, it can be cleaned by rinsing the

tank out with gasoline.

SPARK PLUG

Do not attempt to remove the plug from a hot engine in order

to avoid possible damage to the threads.

Clean or replace the plug if fouled with heavy oily deposits.

Replace the plug if the center electrode is worn rounded at the

end.

Spark gap 0.6-0.7mm (.023”.028") (See fig.22).

Fastening torque =14-15Nm(125-135in.lb)

BEVEL GEAR

After working (40-50) hours, fill with the right quantity of grease.

Remove the screw and put in the lithium-based grease. turning the shaft

manually until grease emerges, then refit the wash the screw (See fig.23).

Fig.21

Fig.23

Fig.20

Fig.22

Loading ...

Loading ...

Loading ...