Loading ...

Loading ...

Loading ...

www.manitowocfsusa.com 800-225-9916 9

Oil Traps:

To ensure proper oil return to the compressor, a P-type oil trap should be installed at

the base of each suction riser of four feet or more. The suction trap must be the same

size as the suction line. Additional traps are necessary for long vertical risers. Add a

trap for each length of pipe (approximately 20 feet) to insure proper oil return. Suction

lines must slope ¼” per 10 feet toward the compressor. Install a suction line trap at the

evaporator outlet if the suction line rises to a point higher than the connection on the

evaporator.

CAUTION

Failure to properly install oil traps can prevent sufficient oil return to the compressor

resulting in premature compressor failure.

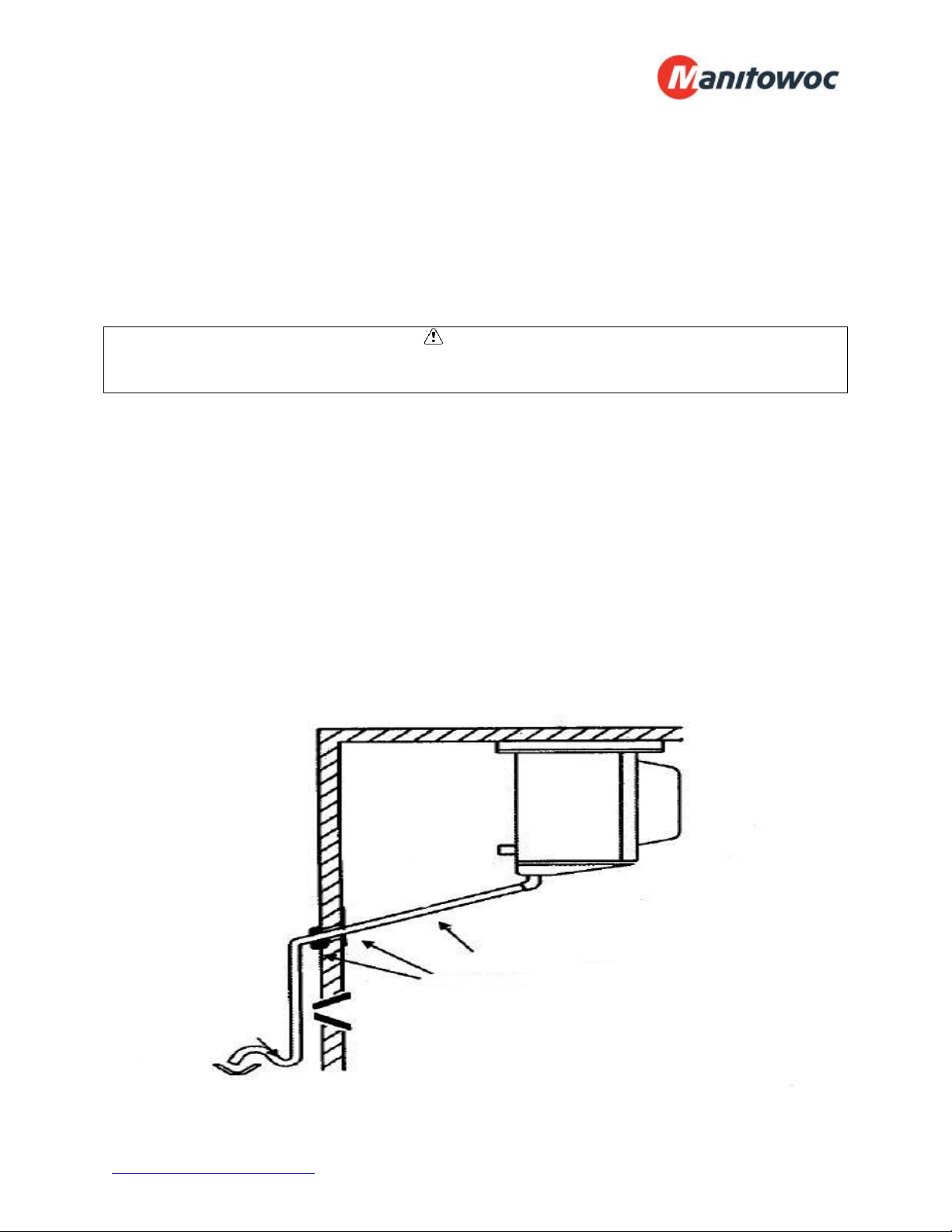

Drain Lines:

Evaporator coil drain lines should be pitched a minimum of ½” per foot to allow proper

drainage and exit the walk-in as quickly as possible. Insulate and seal the drain line

where it passes through the wall. Copper drain line is required. If the refrigerated

space is 33°F or lower, drain line insulation and heat tape are required. Drain lines

must be insulated with minimum ½” thick armaflex. The drain line heat tape must be

wrapped around the copper drain line. Do not locate bends, elbows, or drain traps

within the refrigerated space. Do not reduce the drain line size. Locate a drain line P-

trap outside of the refrigerated space. Any traps exposed to low ambient temperatures

should be wrapped with a drain line heater (provide 20 watts of heat per foot of drain

line at 0°F, 30 watts per foot at -20°F.

P-Trap

Pitch drain line

½” per foot

Seal and

Insulate

Typical Drain Installation

Loading ...

Loading ...

Loading ...