Installation

Instructions

ElectricDryer

37

I

Questions on Installation? Call: 1-8OO-GECARES (US)

or Visit our Web site at: www.GEAppliances.com (US)

BEFOREYOU BEGIN

Read these instructions completely and carefully.

•IMPORTANT -Savethese

instructions for local inspector's use.

•IMPORTANT -Observeall

governing codes and ordinances.

• Note to Installer - Be sure to leave these instructions with

the customer.

• Note to Customer - Keep these instructions with your Use

and Care Book for furore reference.

• Exhausting the dryer to the outdoors is strongly recom-

mended to prevent large amounts of moisture from being

blown into the room.

• Before the old dryer is removed from service or discarded,

remove the dryer door.

• Service information and the wiring diagram are located in

the control console.

• Do not allow children on or in the appliance. Close

supervision of children is necessary when the appliance is

used near children.

FORYOUR SAFETY:

WARNING

• Use only rigid metal or flexible metal 4-in. diameter

ductwork for exhausting to tile outdoors. Never

use plastic or other combustible, easy-to-puncture ductwork.

• This appliance must be properly grounded and installed

as described in these instructions.

• Do not install or store appliance in an area where it

will be exposed to water and/or weather

• Install tile dryer where the temperature is above ,50°F

for satisfactory operation of the dryer control system.

NOTE: Installation and service of this dryer

requires basic mechanical and electrical skills.

It is your responsibility to contact a qualified

installer to make the electrical connections,

I

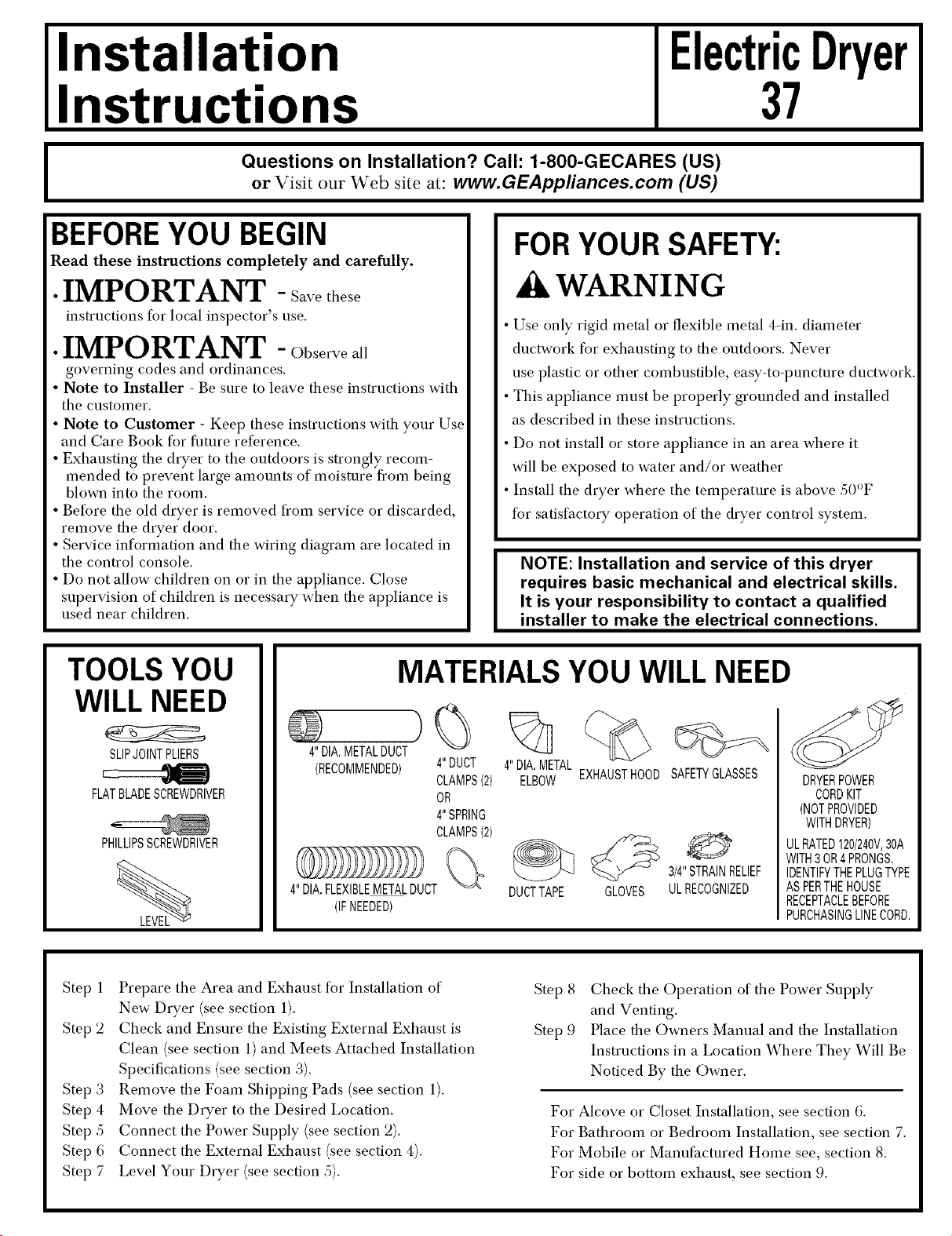

TOOLS YOU

WILL NEED

SLIPJOINTPLIERS

[_

FLATBLADESCREWDRIVER

PHILLIPSSCREWDRIVER

MATERIALSYOU WILL NEED

4" DIA.METALDUCT

4"

(RECOMMENDED) DUCT

CLAMPS(2)

OR

4"SPRING

CLAMPS(2)

4"DIA.FLEXIBLEMETALDUCT

(IFNEEDED)

%

4"DIA.METAL

ELBOW

EXHAUSTHOOD SAFETYGLASSES

_ 3/4"_RELIEF

DUCTTAPE GLOVES ULRECOGNIZED

DRYERPOWER

CORDKIT

(NOTPROVIDED

WITHDRYER)

ULRATED120/240V,30A

WITH3OR4PRONGS.

IDENTIFYTHEPLUGTYPE

ASPERTHEHOUSE

RECEPTACLEBEFORE

PURCHASINGLINECORD.

Step 1

Step 2

Step 3

Step 4

Step 5

Step 6

Step 7

Prepare the Area and Exhaust for Installation of

New Dryer (see section 1).

Check and Ensure the Existing External Exhaust is

Clean (see section 1) and Meets Attached Installation

Specifications (see section 3).

Remove the Foam Shipping Pads (see section 1).

Move the Dryer to the Desired Location.

Connect the Power Supply (see section 2).

Connect the External Exhaust (see section 4).

Level Your Dryer (see section ,_).

Step 8

Step 9

Check the Operation of the Power Supply

and Venting.

Place the Owners Manual and the Installation

Instructions in a Location Where They Will Be

Noticed By tile Owner.

For Alcove or Closet Installation, see section 6.

For Bathroom or Bedroom Installation, see section 7.

For Mobile or Manufactured Home see, section 8.

For side or bottom exhaust, see section 9.

Loading ...

Loading ...

Loading ...