Loading ...

Loading ...

Loading ...

ENGLISH

4

Technical Specifications

Model WBP26HT

Engine type Air-cooling, 2-stroke

Engine model SK1E34F-LE

Power 0.7kW

Displacement 25.4 cm3

Volumes of fuel tank 600 cm³

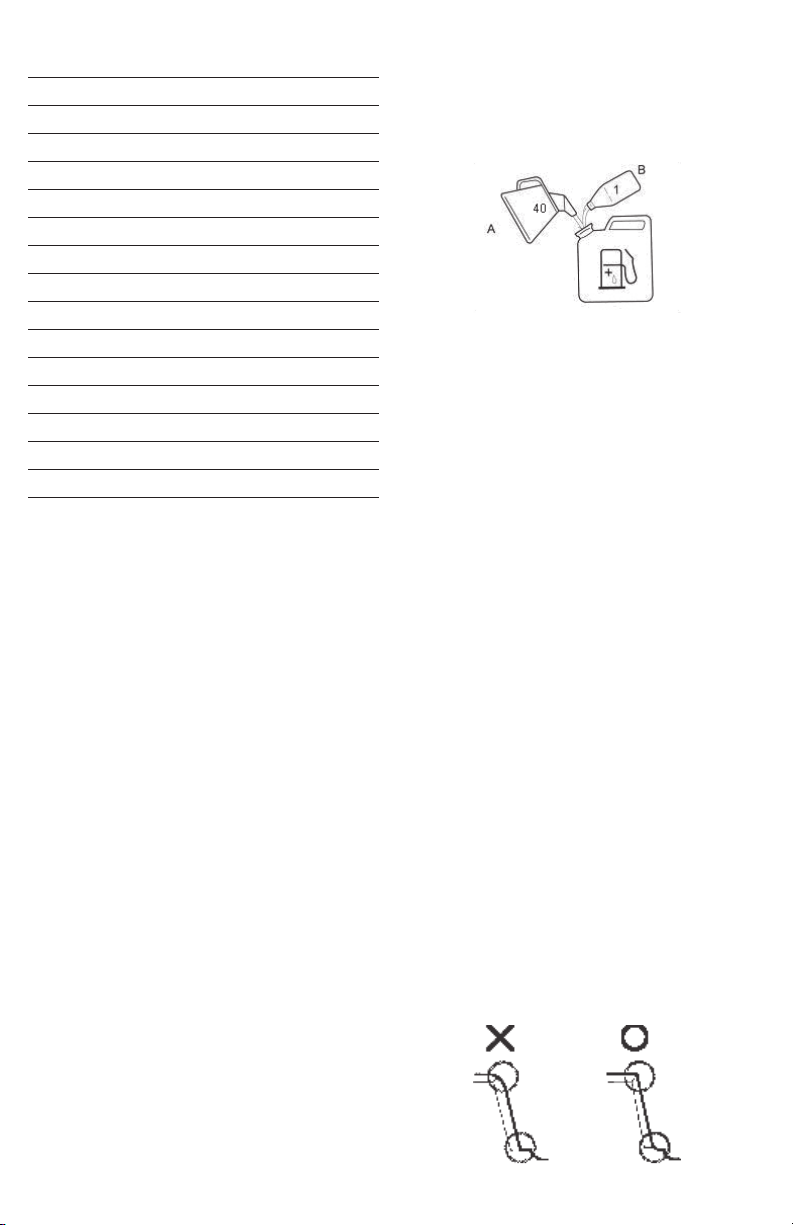

Fuel ratio 40:1

Max engine speed 11500 min

-1

cutting speed 2250 min

-1

Min. Clutch speed 4200min

-1

Engine idling speed 3000±300 min

-1

Blade length 780 mm

Cutting length 600 mm

Max. Cutting dia. 27mm

Unit weight (empty tanks 6.4 kg

Engine Fuel

WARNING: The hedge trimmer is fitted with a

two-stroke engine; use fuel mixed with oil only.

Only fuel the machine in well-lit areas. Avoid fuel

spillage. Never refuel the machine during operation.

WARNING: Do not refill fuel while engine is

running or hot. Let the engine cool down for about

two minutes before refueling. Refueling must not

be carried out near flames, control lamps or spark

producing electrical equipment such as electric

tools, welders or sanders.

Use quality two-stroke oil and make a mixture of 40 parts

petrol to one part oil only (2,5% oil mixed in fuel).

Never use two-stroke oil intended for water-cooled engines.

Never use oil intended for four-stroke engines.

A poor oil quality and/or too high oil/fuel ratio may jeopardise

function and decrease the life time of catalytic converter.

Use at least 90 octane fuel. Unleaded petrol recomended as it

leaves less residues inside the motor and on the ignition plug,

and prolongs the life cycle of the exhaust system. Never use old

or dirty petrol or oil/petrol mixtures.

Avoid contamination with dirt or water in the tank.

1. Make sure the machine is turned off, by turn the engine

switch to the “off” position.

2. Check the fuel level visually by removing the fuel cap and

verifying the fuel level.

3. Shake the fuel container well to ensure the correct mixture

before filling the tank.

4. Fill with unleaded fuel mixed with oil from an approved fuel

container into the fuel tank, because of fuel expands, fill

the tank to the neck of tank only.

5. Turn the fuel cap clockwise to close the fuel tank.

Make sure fuel is not leaking from the rear outlet tube.

Occasionally ignition knocking or clanging can be heard with

high loads. This is normal and no cause for alarm. If ignition

knocking or clanging occurs during normal loads and with

constant motor speed you should change the petrol quality. If

this does not solve the problem contact an authorized specialist

dealer.

When working at continuous high revs a higher octane rating

is recommended.

Check the hand guard

The hand guard prevents hands from coming into contact with

the moving blades, for example, if the operator loses grip on the

front handle.

CAUTION: Check that the hand guard is fitted

correctly. Check that the hand guard is undamaged.

Check the Blade

To ensure good cutting results it is important that the

contact pressure between the blades is correct. The contact

pressure is adjusted by turning the screws on the underside

of the bar clockwise.

When the blades are correctly adjusted the play between

the blades should be 0,6 mm, measured at the screws.

Replace the blades if they are bent or damaged.

Check the cutting edges and reform with flat and round file.

1. Keep the end corner sharp. The best cutting angle should

be 45º.

2. Round the root of the edge.

3. Do not use water during grinding.

Loading ...

Loading ...

Loading ...