Loading ...

Loading ...

Loading ...

Front Tine Tiller » Operator's Manual

MAINTENANCE

Maintaining your

YARD

MAX

front

tine

tiller

will ensure long life

to

the machine

and

its components.

PREVENTIVE

MAINTENANCE

Clean the

tiller

underside

of

the tine shield after

each

use.

The

dirt

washes

off

tines easier

if

rinsed

off

immediately instead

of

after

it

dries.

1.

Turn

off

the engine

and

disengage all command levers. The

engine must

be

cool.

2.

Keep the engine's

throttle

lever in its SLOW position and

remove the spark plug

wire

from the spark plug

and

secure.

3.

Inspect the general condition

of

the

front

tine tiller. Check

for

loose screws, misalignment

or

binding

of

moving parts,

cracked

or

broken parts,

and

any

other

condition

that

may

affect its safe operation.

4.

Use

a soft brush, vacuum

or

compressed air

to

remove all

contaminants from the machine. Then

use

high quality light oil

to

lubricate all moving parts.

5.

Replace the spark plug wire.

\.

Never

use

a

"pressure

washer" to

clean

your unit.

Water

can

penetrate tight

areas

of

the

machine

and

its

transmission

case

and

cause

damage

to

spindles,

gears,

bearings,

or the

engine.

The

use

of

pressure

washers will result

in

shortened life and reduce

serviceability.

LUBRICATION

Remove the tine assemblies

to

lubricate the tine shafts

at

least

once every

season.

The worm gear housing

is

pre-lubricated

and

sealed at the factory.

At

the beginning

of

each

season,

make

sure there

is

enough lubricant inside the worm gear housing.

Use

portable tool lithium

#0

grease such

as

Lubricate 6300AA ,

Lubricate GR-132,

or

Multifak,

e.g.

EP-0.

1.

Remove right side tines

and

place the

tiller

on level surface.

Allow

the transmission

to

cool before filling

with

grease.

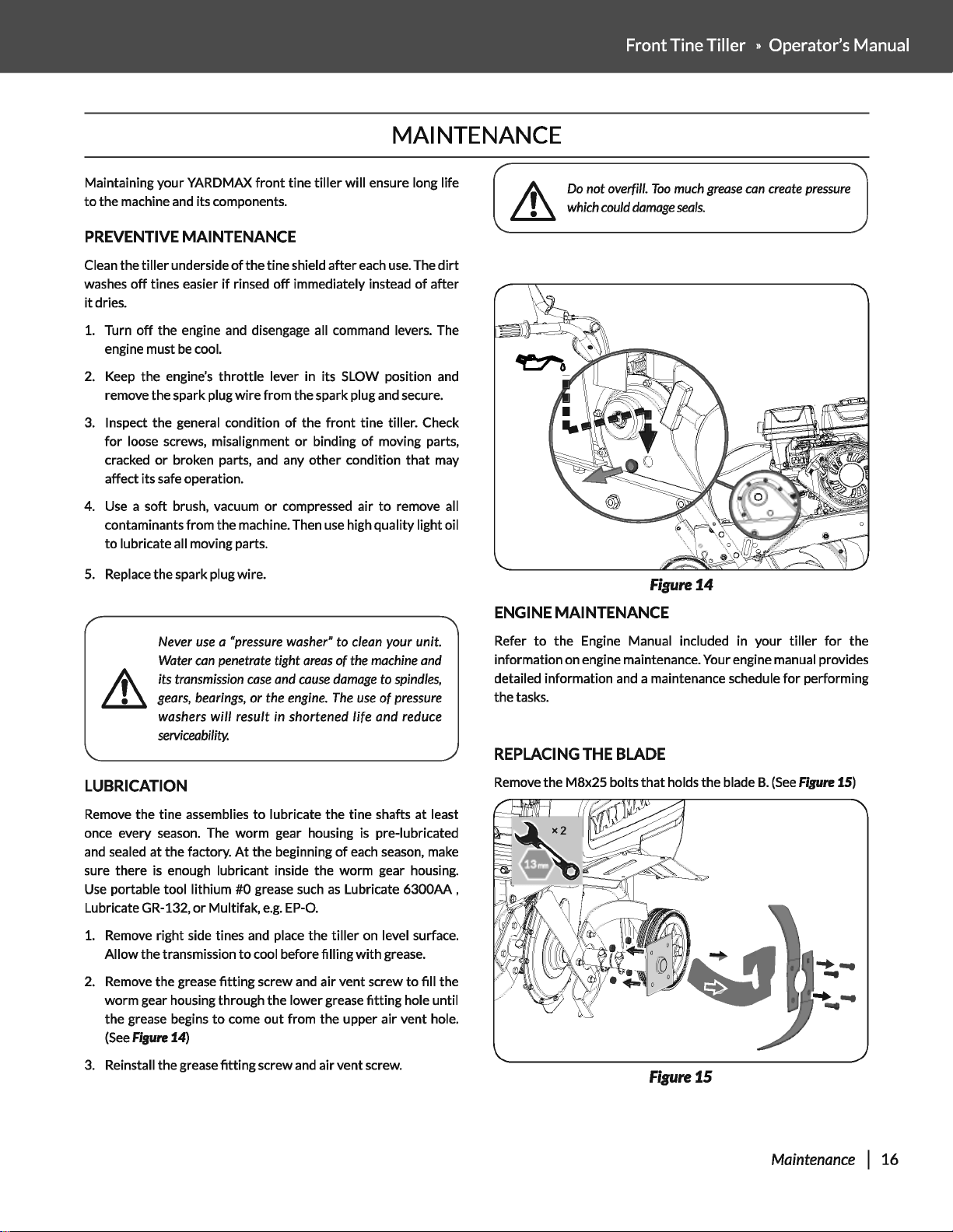

2.

Remove the grease

fitting

screw

and

air vent screw

to

fill the

worm gear housing through the lower grease fitting hole until

the grease begins

to

come

out

from the upper air vent hole.

(See

Fipre

14)

3.

Reinstall the grease fitting screw

and

air vent screw.

Do

not overfill.

Too

much

grease

can

create

pressure

which

could

damage

seals.

Figure14

ENGINE

MAINTENANCE

Refer

to

the Engine Manual included in your

tiller

for

the

information on engine maintenance. Your engine manual provides

detailed information

and

a maintenance schedule

for

performing

the tasks.

REPLACING THE BLADE

Remove the M8x25 bolts

that

holds the blade

B.

(See

Fipre

15)

Figure

15

Maintenance

I 16

Loading ...

Loading ...

Loading ...