Loading ...

Loading ...

Loading ...

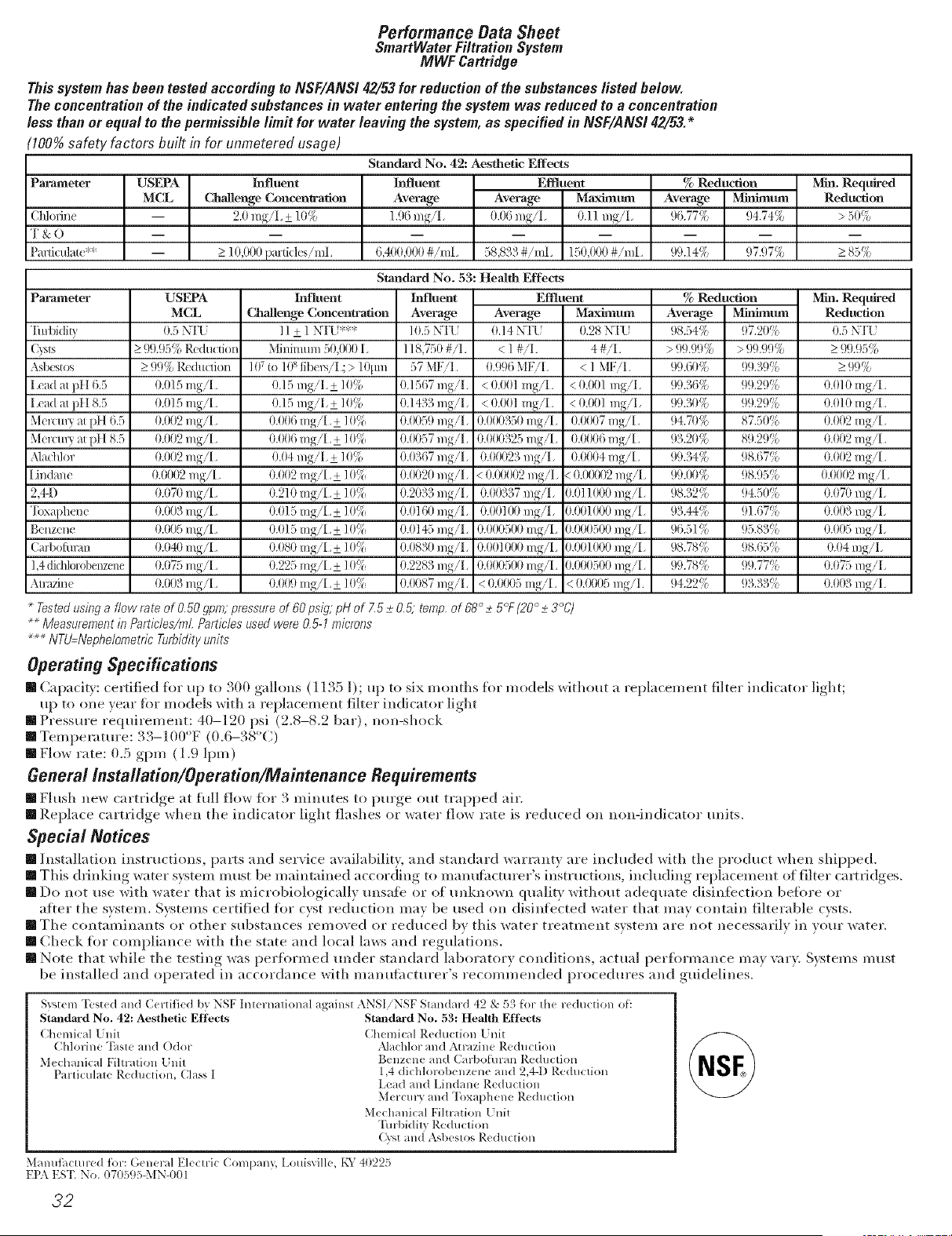

Performance Data Sheet

SmartWater Filtration System

MWF Cartridge

This systemhas been tested accordingto NSF/ANSI42/53for reductionof the substanceslisted below.

The concentration of the indicated substances in water enteringthe systemwas reduced to a concentration

less thanor equal to the permissible Ibnit for water leaving the system, as specified in NSF/ANSI42/53.*

€100%safety factors built in for unmetered usage)

USEPA

MCL

Parameter

Chlofin_

T&O

Panicttlat_ **

m

m

m

Influent

Challenge Concenlrafion

2.0 mg/L + ]0%

_>10,000 pardck s/mI,

Stmldard No. 42: Aesthetic Effects

hffluent Effluent

Average Average Maximum

].96 rag/I, 0.06 rag/I, 0.11 rag/I,

6,4(10,000 #/mL 58,833 #/mL 130,000 #/mL

Standard No. 53: Health Effects

Parameter USEPA

MCL

05 NT_

"Ihrbklit_

Cvsls _>99.95% Reduction

Asbestos _>99% Rcducfiola

1;:ad at pI {6.5 0.0] 5 mg/L

I_ead at pl {8.5 0.012,mg/L

Mert ur} at pH 6.5 0.002 mg/L

.\ler_ my at pH 8.5 0.002mg/L

Alachlor 0.002 rag/I,

l in(lane 0.0002mg/L

]xffluent

Challenge Concentration

] ] + ] KI'/5"**

Minim(m( 50,000 I<

] (F to ] 0s tibe/_/I; > ]0tim

0.12, rag/l< + ]0%

0.12, rag/I, + ]0%

0.006 mg/L + ]05(

0.006mg/L + ]0{(

0.04 rag/I, + ]0!(

0.002 mg/L + ]0{(

0.210 mg/L + ]0{(

0.015 mg/L + ] 0{(

0.015 mg/L + ] 0{(

hffluent

Average

] 0.5 NT[ 5

]] 8,75(} #/1,

57 MF/I<

0.1567 rag/l<

0.1433 rag/I,

0.0059 rag/I,

0.0057 rag/I,

0.0367 rag/I,

0.0020 rag/I,

Effluent

Average Maximum

0.14 NT/ 0.28 NT{

< ] #/I, 4 #/L

0.996 MF/L < ] \IF/I<

< 0.001 mg/L < 0.(}01 mg/L

< (}.001 mg/L < (}.(}01 rag/I,

0.000350 mg/L 0.0007 mg/L

0.000325mg/L 0.0006mg/L

0.00023 rag/I, 0.0{X)4 mg/L

< 0.00{)02 rag/I, < 0.00002 mg/L

2,44) 0.070mg/L 02033mg/I, 0.00337mg/I, 0.0]]000mg/I,

"Ibxaph_ne 0.003mg/L 0.0]60rag/I, 0.00]00rag/I, 0.(_)]000mg/I,

Benz_ne 0.005 mg/L 0.0145 rag/I, 0.000500 mg/L 0.()00500 mg/I,

Carbofimm 0.040mg/L 0.080mg/l,+]0!( 0.0830rag/I, 0.00]000mg/I, 0.00]000mg/I,

],4di&lorol>enzene 0.075mg/L 0.225mg/L+]0[_( 0.2283mg/L 0.0005(X)mg/L 0.(X)0500mg/L

Atmzine 0.003mg/L 0.009mg/L+_]0!_( 0.0087mg/L <0.0005mgq_ <0.0005rag/l.

% Reduc6on

Average

96.77%

99.14%

_Ulffl

94.74%

{)7.97%

% Reduction

Average Minlmtml

98.54% 97.20%

> 99.99% > 99.{)9%

99.6(1% {)9.39%

99.36% 99.29%

99.30% 99.29%

94.70% 87.50!_(

93.20% 89.29!_(

99.34% 98.67%

99.00% 98.95[(

98.32!( 94.50!_(

93.44[( 91.67[(

96.5] {( 95.83!(

98.78!( !)8.65!(

9!).78!( 99.77{_(

94.22!( 93.33!(

Min. Required

ReducGon

> 50%

_>85%

Min. Required

Reduction

0.5 NT/5

_>99.95%

_>99%

0.010 mg/L

0.010 mg/L

0.002mg/L

0.002mg/L

0.002 mg/L

0.0002mg/L

0.070mg/I,

0.003 rag/I,

0.005 rag/I,

0.04 rag/I,

0.075 mg/L

0.003 rag/l,

* Testedusinga flowrateofO.5Ogpm;pressure of GOpsigpHofZS_+ 0.5, temp. of 68°_+ 5°F{20°_+3°C1

** Measurement b Particles/ml. Particles used were 0.5-1 microns

*_ NTU=Nephelometric Turbidity units

Operatino Specifications

[] Capa(it? : cerGfied tot up to 300 gallons (I 135 1); up to six months h)r models _dthout a replacement tiher indicator light;

up to one }ear fi)r models with a replacement fiher indicator light

[] Pressure requirement: 40-120 psi (2.8-8.2 bar), non-shock

[] Tempera(re'e: 33-100°F (0.6-38°(2)

[] Fhwv rate: 0.5 gpm ( 1.9 lpm)

General Instaflation/Operation/Maintenance Requirements

[] Fhlsh new cartridge at hill f]o_ for ,, minutes to purge ()tit trapped air.

[] Replace cartridge when the indicator light flashes or water flow rate is reduced (m non-indicator units.

Special Notices

[] Installation instructions, parts and service availabilit}, and standard x<arrant) are included *_ith the product when shipped.

[] This drinking >,ater s}stem must be maintained according to mamffactmer's instructions, inchlding replacement of filter carQJdges.

[] Do not use Mth water that is microbiologicall} unsafe or of unknown qualit} without adequate disinfectioil before or

after the sxstem. Sxstems certified for c}st reductioil max be used on disinfected water that me} contain filterable cxsts.

[] The contaminants or other substances l'enioved o1" reduced b} this water treatment s}stem are not necessaril} in xour water.

[] Check for compliance with the state and local laws and regulations.

[] Note that while the testing *sas performed under standard laborator} conditions, actual performance me} Xr_*'}i S}stems must

be installed and operated in accordance with manuihcturer's recommended procedures and guidelines.

Standard No. 42: Aesthetic Effects

Chemical Unit

Chlorine Taste and Odor

Mechanical Fihration Lnit

Particulate Reduction, Class I

System "[\,sted and Certified by NSF International against ANSIiNSF Standard 42 & 53 for the reduction of:

Standard No. 53: Health Effects

Chemical Reduction Unit

Alachlor and Atrazine Reduction

Benzene and (iarbofllran Reduction

1,4 dichlorobenzene and 2,44) Reduction

Lead and Lindane Reduction

Mercury and Toxaphene Reduction

Mechanical Filtration [nit

Turhidity Reduction

Cyst and Asbestos Reduction

Manufactul-ed fin-: General Electric Compal_y, Louisville, t\T 40225

Elt\ ES'IL No. 070595-MN-001

32

Loading ...

Loading ...

Loading ...