Loading ...

Loading ...

Loading ...

– 13 – – 14 – – 15 – – 16 –

–

17 – – 18 –

– 19 – – 20 –

– 21 – – 22 – – 23 –

Out-of-Beam Indication

The receiver has an out-of-beam (OOB) function. When it is turned on, the LED

grade display indicates that the receiver has moved beyond the vertical laser-reception

range. A sequence of LEDs indicates which direction to move the blade or cutting

edge to pick up the laser beam. If the receiver is above the beam, move the edge down.

If the receiver is below the beam, move the edge up. The sequence stops as soon as a

laser signal is received. Otherwise, the function shuts off after two minutes.

The factory default setting is for the out-of-beam function to be on. The LED display

sequences inward toward on-grade to indicate that the function is on. To turn the

function off, press the two outside buttons (Blade Tilt and Display Brightness) at the

same time. The LED display sequences outward from on-grade to indicate that the

function is off.

Slope Matching

The blade-tilt indicator can be nulled or set to zero for a blade slope other than

level. This function is used for matching an existing slope or setting the blade to a

predetermined slope.

The factory default setting for the blade-tilt indicator is level.

To change the blade-tilt indicator at a slope other than level:

1. Position the blade at the desired slope. Make sure the receiver is properly aligned

with the blade from side to side and front to back.

2. With the receiver on, press and hold the power button and immediately press

and hold both the blade-tilt button and the display-brightness button. Continue

holding all three buttons until a “0” symbol followed by a “Y” symbol briefly

displays. The blade slope is now nulled at the existing slope.

3. To reset the blade-tilt indication back to level, position the blade to level using a

four-foot level or other method. Repeat the above procedure with the blade level.

This procedure may also be used to correct the display when a mast is not aligned

properly to the blade.

Excavating

When an excavator or backhoe is being used, the dipper arm should be vertical or near

vertical and the bucket positioned so that it can easily be put in the same position each

time a grade reading is taken. The bucket can be fully extended or curled as long as

the position is consistent when grade readings are taken. The receiver can be set up in

the trench or out of the trench if the cut elevation can be determined.

In-Trench Setup

7. Mount the receiver on the mast, and adjust the dipper arm so that the receiver is

within the plumb range—LEDs solid. Adjust the plumb-accuracy indication if

desired.

8. Slide the receiver up or down until you get a solid on-grade display.

9. Select the desired deadband and begin excavating.

10. Take grade readings with the bucket in the grade-checking position and the grade-

display LEDs solid.

11. Take a sample reading with the bucket “on-grade” and check to make sure the

elevation is correct.

Out of Trench Set-Up

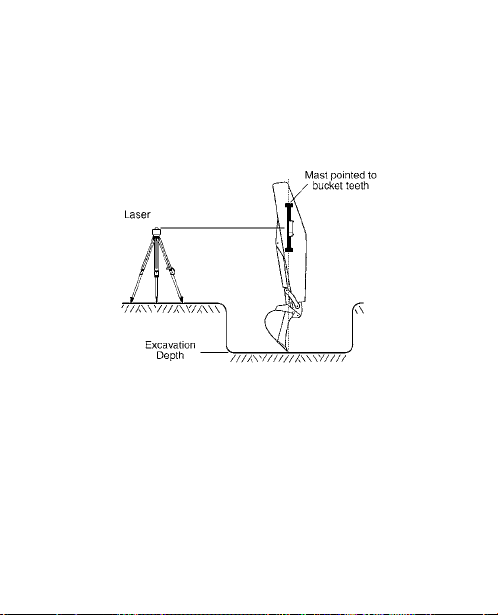

3. Determine the distance from the laser to the bottom of the trench (L). This is the

setup length. The length is the height of the instrument (HI) plus the depth of cut

from the benchmark to the bottom of the trench (C).

4. Mount the mast on the side of the dipper arm.

5. Point the mast at the bucket teeth as illustrated if checking grade with the bucket

fully extended. (If checking grade with the bucket curled or other position, point

the mast to the point of the bucket that makes contact with the ground.)

6. Position the receiver so the setup length (L) is the distance from the point of the

bucket that makes contact with the ground to the offset on-grade symbol on the

back label. (Set up to center on-grade symbol if center on-grade is being used).

7. Turn on the receiver and select offset on-grade and the desired deadband.

8. Adjust the plumb-accuracy indication if desired. (Select center on-grade if set to

center symbol).

9. Begin excavating.

10. Take grade readings with the bucket in the grade-checking position and the grade-

display LEDs solid.

11. Take a sample reading with the bucket “on-grade” and check to make sure the

elevation is correct.

Installation

General

WARNING: Follow all safety precautions as discussed in the machine’s user

guide. Also follow all excavation and safety requirements and practices.

1. Set up the laser in an appropriate location for receiver visibility and efficient

machine operation. For more information about laser setup, please refer to the

laser’s user guide. Turn on the laser.

Note: Operating distances depend on the rotating laser power. The receiver can

pick up the beam from all directions (360°), but it requires a clear line of sight to

the laser.

2. If your laser has selectable rotation speeds, select a high rotation speed. The receiver

can process speeds up to 1200 RPM.

3. To mount the receiver on the mast, turn the top and bottom mounting knobs

counterclockwise until the clamps in back open enough to fit around the mounting

mast. Place the receiver on the mast. Turn the knobs clockwise to tighten the

clamps.

Note: The receiver will mount to round tubing that has a 42 mm to 50 mm

(1.66 in. to 2.00 in.) outside diameter or to 38 mm (1

1

/2 in.) square tubing.

4. To remove the receiver from the mast, loosen the two clamps.

The blade-tilt and plumb indications are measured

inside the receiver. The blade tilt indicates side-to-side

position. Plumb indicates front-to-back position. Masts

and receivers must be properly aligned to the machinery

for accurate indications.

2. Set up the laser in an appropriate location for receiver visibility and efficient

machine operation. Turn on the laser.

3. Turn on the receiver, select center on-grade (grading mode), and select the smallest

deadband.

4. To mount the receiver on the mast, turn the top and bottom mounting knobs

counterclockwise until the clamps in back open enough to fit around the mounting

mast. Place the receiver on the mast.

5. Slide the receiver up or down until on-grade is indicated. Adjusting the height of

the laser may be necessary.

Note: Alternatively, if the height of instrument (laser beam) to finished elevation

length is known, the receiver can be set by measuring this distance from the cutting

edge of the blade to the center on-grade mark on the back of the receiver label.

6. Face the LED grade display toward the machine and turn the mounting knobs

clockwise to tighten the clamps

7. Select the desired deadband and brightness.

Note: The LED grade display indicates which way to move the blade using the

machine’s controls to maintain an on-grade reading.

8. Make a sample pass with the blade “on-grade” and check to make sure the

elevation is correct.

Specifications

Beam Reception Range 360 degrees

Operating Range Over 460 m (1500 ft) radius, laser dependent

Laser RPM Minimum: 105; Maximum: 1200

Vertical Reception 171 mm (6.75 in.)

Accuracy: Fine Standard Wide

Center On-Grade

(Grading)

5 mm

(0.20 in.)

10 mm

(0.40 in.)

20 mm

(0.80 in.)

Offset On-Grade

(Excavation)

12 mm

(0.50 in.)

25 mm

(1.0 in.)

50 mm

(2.0 in.)

Blade-Tilt & Plumb-Swing Accuracy

± 0.5°, ± 1.5°, ± 2.5°

Display Output Bright or Dim

Automatic Control Capability Yes, with CB20, CB25 and CB30 Control Box

Power Options Alkaline – 4 x “C” Cell – Standard

Nickel Metal Hydride – 4 x “C” Cell

Power Cable – 10 –30 V dc

LR50 Battery Life – Alkaline

LR50W Battery Life – Alkaline

(Continuous in beam)

60 hours, Display Dim / 45 Hours, Display Bright

30 hours, Display Dim / 20 Hours, Display Bright

LR50 Battery Life – Ni-MH

LR50W Battery Life – Ni-MH

(Continuous in beam)

45 hours, Display Dim / 30 hours, Display Bright

20 hours, Display Dim / 15 hours, Display Bright

Battery Recharge Time 3 – 4 hours

Automatic Shutoff 75 minutes with no laser beam

Out-of-Beam Indication High and Low, Selectable On or Off

Remote Display Option Yes

Dimensions (LxWxD)

343 mm x 142 mm x 149 mm

(13.50 in. x 5.58 in. x 5.88 in.)

Mounting Pipe

Round Tube (Outside Diameter)

Square Tube

42 mm to 50 mm (1.66 in. to 2.00 in.)

38 mm (1 ½ in.)

Operating Temperature –20 °C to +60 °C (–4 °F to 140 °F)

*Specifications subject to change without notice

Declaration of Conformity

This receiver to which this declaration relates is in conformity with the essential

requirements and other relevant requirements of the Directive 2004/108/EC (EMC),

Directive 2006/95/EC (LVD) and Council Directive 1999/5/EC R&TTE.

Safety: (article 3.1a) BS EN60950-1: 2006/A12:2011

EN 62311:2008

EMC: (article 3.1b) ETSI EN 301 489-1 V1.9.2 (2011-09) in accordance with

the specific requirements of CISPR22 Class A

ETSI EN 301 489-17 V2.1.1 (2009-05)

Spectrum: (article 3.2) ETSI EN 300 328 V1.7.1 (2006-10), EN61000-9-2,

EN61000-9-3, EN61000-9-6, EN61000-9-8

We hereby declare that the equipment specified above conforms to the above

Directive(s).

Trimble Navigation Ltd. August 24, 2012

5475 Kellenburger Road

Dayton, OH 45424-1099 U.S.A.

Warranty

Trimble warrants the receiver to be free of defects in material and workmanship for a

period of two years.

Trimble or its authorized service center will repair or replace, at its option, any

defective part for which notice has been given during the warranty period. If required,

travel and per diem expenses to and from the place where repairs are made will be

charged to the customer at the prevailing rates.

Customers should send the product to the nearest authorized service center for

warranty repairs, freight prepaid. In countries with Trimble subsidiary service centers,

the repaired product will be returned to the customer, freight prepaid.

Any evidence of negligent, abnormal use, accident, or any attempt to repair the

product by other than factory-authorized personnel using Trimble certified or

recommended parts, automatically voids the warranty.

The foregoing states the entire liability of Trimble regarding the purchase and use of its

equipment. Trimble will not be held responsible for any consequential loss or damage

of any kind.

This warranty is in lieu of all other warranties, except as set forth above, including

any implied warranty merchantability of fitness for a particular purpose, are hereby

disclaimed. This warranty is in lieu of all other warranties, expressed or implied.

Low-Battery Warning

The receiver has low-battery warning LEDs. During

normal operation with good batteries, the LEDs

are off. When the batteries are low, the LEDs begin

flashing. When the warning occurs, the receiver

continues to operate as normal, but about 90

minutes of battery life remain. When the batteries are too low for normal operation,

the LEDs remain on, the four corner grade-display LEDs flash, and the receiver no

longer receives laser signals. Replace the batteries (or recharge them if you’re using

rechargeable batteries). The warning does not operate when the receiver is connected

to machine power via a power cable.

Grading

1. Position the machine and dig to the desired finished elevation.

2. Position the bucket in the grade-checking position at the finished elevation.

3. Set up the laser in an appropriate location for receiver visibility and efficient

machine operation. Turn on the laser.

4. Mount the mast on the side of the dipper arm.

5. Point the mast at the bucket teeth as illustrated if checking grade with the bucket

fully extended. (If checking grade with the bucket curled or other position, point

the mast to the point of the bucket that makes contact with the ground.)

6. Turn on the receiver, and select the offset on-grade and the smallest deadband.

Sequence to

lower implement

Sequence to

raise implement

Out of Beam Indication ON

Typical excavator

installation

Typical dozer

installation

1. Position the machine so the blade can be set to the desired finished elevation

(typically on a benchmark or hub stake).

Laser

Center

On-grade

Finished Elevation

Benchmark

"Y" symbol "O" symbol

1. Set the laser up in an appropriate location for receiver visibility and efficient

machine operation and turn it on.

2. Place the bucket in the grade-checking position and situate the machine so a

measurement can safely be obtained on the dipper arm. The dipper arm may be

set more horizontal to the ground for convenient measurements if necessary.

Notice to Our European Union Customers

For product recycling instructions and more information,

please go to: www.trimble.com/environment/summary.html

Recycling in Europe

To recycle Trimble WEEE,

call: +31 497 53 2430, and

ask for the ÒWEEE associate,Ó or

mail a request for recycling instructions to:

Trimble Europe BV

c/o Menlo Worldwide Logistics

Meerheide 45

5521 DZ Eersel, NL

Make sure dozer mast is vertically aligned with the blade (both front-to-back and side-

to-side) when the blade is in its normal operating position.

For excavation, the mast typically points towards the bucket teeth. For additional

installation details, see “Slope Matching.”

Plumb axis

rotation

Blade tilt

axis rotation

Trimble

Spectra Precision Division

5475 Kellenburger Road

Dayton, Ohio 45424-1099

U.S.A.

+1-937-245-5600 Phone

www.trimble.com

© 2005-2013, Trimble Navigation Limited. All rights reserved.

Reorder PN 0312-0450 (04/13)

Loading ...

Loading ...

Loading ...