Loading ...

Loading ...

Loading ...

• Tominimizepossibleshockhazard,thecordmustbe

pluggedintoamating,3 prong,ground-typeoutlet,grounded

inaccordancewithlocalcodesandordinances.Ifamating

outletisnotavailable,itisthepersonalresponsibilityand

obligationofthecustomertohavetheproperlygrounded

outletinstalledbyaqualifiedelectrician.

• If codespermitandaseparategroundwireisused,itis

recommendedthataqualifiedelectriciandeterminethatthe

groundpathisadequate.

• Donotgroundtoagaspipe.

• Checkwithaqualifiedelectricianifyouarenotsurethe

washerisproperlygrounded.

• Donothaveafuseintheneutralorgroundcircuit.

GROUNDING iNSTRUCTiONS

For a grounded, cord=connected washer:

This washer must be grounded. In the event of a malfunction

or breakdown, grounding will reduce the risk of electrical

shock by providing a path of least resistance for electric

current. This washer is equipped with a cord having an

equipment-grounding conductor and a grounding plug. The

plug must be plugged into an appropriate outlet that is

properly installed and grounded in accordance with all local

codes and ordinances.

WARNING: improper connection of the equipment-

grounding conductor can result in a risk of electric shock.

Check with a qualified electrician or serviceman if you are in

doubt as to whether the appliance is properly grounded.

Do not modify the plug provided with the appliance - if it will

not fit the outlet, have a proper outlet installed by a qualified

electrician.

For a permanently connected washer:

This washer must be connected to a grounded metal,

permanent wiring system, or an equipment grounding

conductor must be run with the circuit conductors and

connected to the equipment=grounding terminal or lead on

the appliance.

INSTALLATIONINSTRUCTIONS

Excessive Weight Hazard

Use two or more people to move and install washer.

Failure to do so can result in back or other injury.

IMPORTANT: Position the washer so that the rear of the washer

is within approximately 3 ft (900 ram) of its final location.

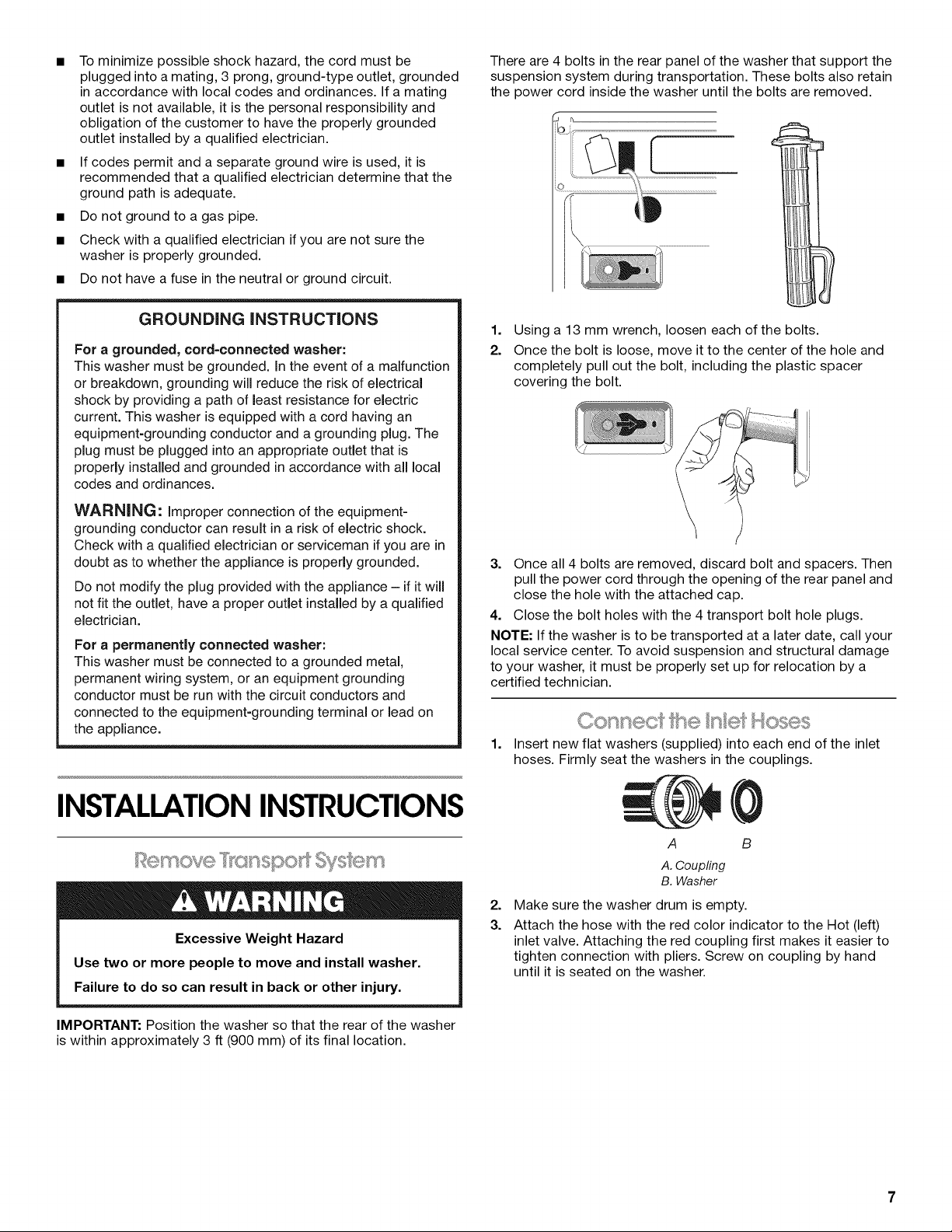

There are 4 bolts in the rear panel of the washer that support the

suspension system during transportation. These bolts also retain

the power cord inside the washer until the bolts are removed.

1.

2.

Using a 13 mm wrench, loosen each of the bolts.

Once the bolt is loose, move it to the center of the hole and

completely pull out the bolt, including the plastic spacer

covering the bolt.

3. Once all 4 bolts are removed, discard bolt and spacers. Then

pull the power cord through the opening of the rear panel and

close the hole with the attached cap.

4. Close the bolt holes with the 4 transport bolt hole plugs.

NOTE: If the washer is to be transported at a later date, call your

local service center. To avoid suspension and structural damage

to your washer, it must be properly set up for relocation by a

certified technician.

1.

2.

3.

Insert new flat washers (supplied) into each end of the inlet

hoses. Firmly seat the washers in the couplings.

A B

A. Coupling

B. Washer

Make sure the washer drum is empty.

Attach the hose with the red color indicator to the Hot (left)

inlet valve. Attaching the red coupling first makes it easier to

tighten connection with pliers. Screw on coupling by hand

until it is seated on the washer.

Loading ...

Loading ...

Loading ...