Loading ...

Loading ...

Loading ...

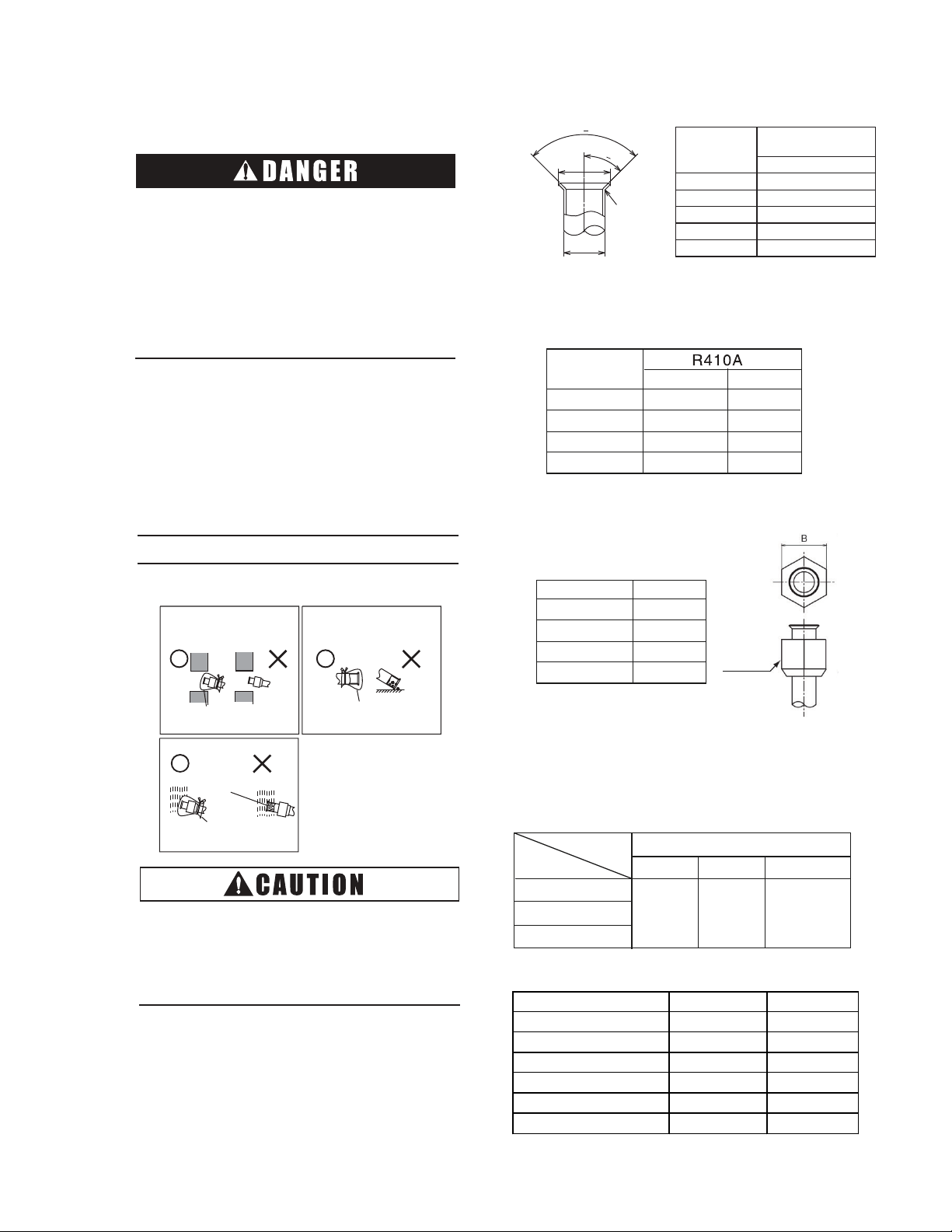

● Piping Thickness and Material

Use the pipe as below.

Thickness Material

Diameter

● Flare Nut Dimension

Use the flare nut as below.

<Flare Nut Dimension B in(mm)

Diameter R410A

Flare Nut

8

Use refrigerant R410A in the refrigerant cycle.

Do not charge oxygen, acetylene or other

flammable and poisonous gases into the

refrigerant cycle when performing a leakage

test or an air-tightness test. These types of

gases are extremely dangerous and can

cause an explosion. It is recommended that

compressed air, nitrogen or refrigerant be

used for these types of tests.

5.1 Piping Materials

(1) Prepare locally-supplied copper pipes.

(2) Select the piping size from the Table 5.1.

(3) Select clean copper pipes. Make sure

there is no dust and moisture inside of the

pipes. Blow the inside of the pipes with

nitrogen or dry air, to remove any dust or

foreign materials before connecting pipes.

NOTE

● Cautions for Refrigerant Pipe Ends

When installing pipe through

the wall, secure a cap at the

end of the pipe.

Correct

CorrectIncorrect Incorrect

Correct Incorrect

HoleHole

Attach a cap

or vinyl tape.

Attach a cap

or vinyl tape.

Attach a cap

or vinyl bag with

rubber band.

Do not place the pipe

directly on the ground.

Rain water can

enter.

5. Refrigerant Piping Work

O

O

O

O

● Flaring Dimension

Perform the flaring work as shown below.

● Cap the end of the pipe when the pipe is to

be inserted through a hole.

● Do not put pipes on the ground directly

without a cap or vinyl tape at the end of the

pipe.

work according to the tables.

Table 5.2 Limitation of Outdoor Unit

Outer Diameter of Pipe

Gas Liquid

5.2 Refrigerant Piping Work

(1) Ensure that the directions for refrigerant piping

Diameter

Branch Pipe

B-102H

Capacity

(Btu/h)

36

48

60

Table 5.3 Indoor Unit Pipe Model

Table 5.1 Piping Size

in (mm)

Diameter

(d)

A

+0

-0.02 (-0.4)

R410A

1/4 (6.35) 0.36 (9.1)

3/8 (9.52) 0.52 (13.2)

1/2 (12.7) 0.65 (16.6)

5/8 (15.88) 0.78 (19.7)

3/4 (19.05) (

)

1/64 ~ 1/32R

A

d

90

o

+

2

o

45

o

+

2

o

in (mm)

1/4 (6.35)

3/8 (9.52)

1/2 (12.7)

5/8 (15.88)

0.031 (0.8)

0.031 (0.8)

0.039 (1.0)

0.031 (0.8)

1/4 (6.35)

21/32 (17)

3/8 (9.53)

7/8 (22)

1/2 (12.7)

1-1/32 (26)

5/8 (15.88)

1-5/32 (29)

5/8 (15.88)

3/8 (9.53)

in (mm)

in (mm)

Capacity(kBtu/h) Gas Pipe Liquid Pipe

0~17 1/2(12.7) 1/4(6.35)

19~22(4-Way Cassette) 1/2(12.7) 1/4(6.35)

19(Ducted) 5/8(15.88) 1/4(6.35)

22(Ducted) 5/8(15.88) 3/8(9.53)

18~22(Wall-Mounted) 5/8(15.88) 3/8(9.53)

24~ 5/8(15.88) 3/8(9.53)

Loading ...

Loading ...

Loading ...