Loading ...

Loading ...

Loading ...

CULINARIAN SERIES

39

CAUTION!

When connecting unit to Propane (LP)

gas. Make certain the propane tank is equipped

with

i

ts own

high

-

pressure regulator in addition to

the

pressure regulator supplied with the appliance t

he

pressure & the gas

supplied

to the appliance

regulator

must not, exceed 14"

(

37 mb) water

column. A

pressure test point is provided near

the regulator

behind the kick plate

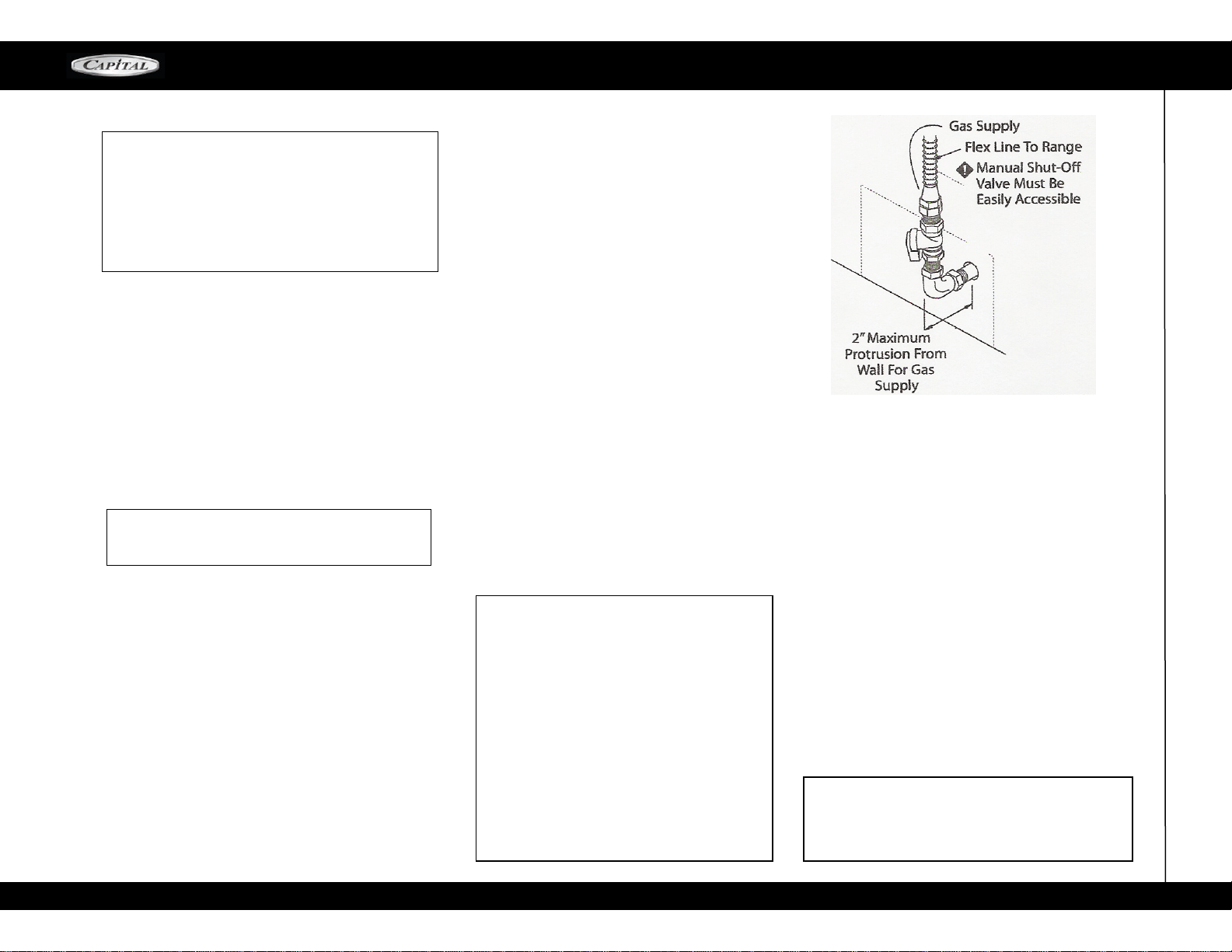

A manual shut off valve must be installed external

to

the range in an accessible location from the front

for

shutting off the gas supply when required.

The supply line MUST NOT protrude beyond the

back of the range.

Ensure that the gas supply is turned OFF at the

externalshut

-

offvalve before connecting the range.

The

gas

supply connection must be made by an

experienced technician and in accordance with

local codes or ordinances. In the absence of local

codes or ordinances, please refer to National Fuel

Gas Code ANSI Z223.1 / NFPA54

-

Current Issue.

The range is

supplied

with its ownpressureregulator

Use 5/8" diameter flex line to connect between the

gas supply and the appliance manifold pipe, which

exists at the upper left rear of the appliance. The

appliance manifold pipe connection is 1/2". Use

caution to avoid crimping the 5/8" flex line.

NOTE: the flex line for the gas supply must be

metal and approved by an approved certifying

agency (AGA, CGA, CSA, UL or CUL). NEVER use

a hose made of rubber or other synthetic material

as the heat may cause the hose to melt and de-

velop leaks, thus causing fires, physical and prop-

erty damage.

Always use pipe dope or Teflon tape on the pipe

threads, and be careful not to apply excessive pres-

sure when tightening the fittings.

Leak testing of the appliance shall be in accor-

dance with the manufacturer's instructions.

Turn on gas and check supply line connections for

leaks using a soap solution.

Never use a flame of

any sort to test for leaks.

CAUTION! The appliance must be isolated from the

gas supply piping system by closing its individual

manual shut

-

off valve during any pressure testing

of the gas supply piping system at test pressures

equal to or less than 112 psig (3.5kPa.).

The Appliance and its individual shut off valve

must be disconnected from the gas supply piping

system during any pressure testing of the system

at test pressures in excess of 1/2 psig (3.5kPa.).

When checking the manifold gas pressure, the inlet

pressure to the regulator should be at least 6.0".

DO NOT attempt any adjustment of the pres-

sure regulator.

TESTING AND ADJUSTMENTS

Install any loose components, such as burner caps

and

grates, oven racks that may have been removed

earlier to

facilitate moving the appliance. Be certain

that burner

caps seats properly

into the alignment slots in the burner

bases. Before

testing operation of the appliance, verify that

the unit

and the gas supply have been carefully

checked

for leaks and that the unit has been connected

to the electrical power supply. Turn the manual gas shut

-

off valve to the open position. Check the

operation of

the sealed gas burners by pushing

and turning each

knob counterclockwise to "Hl".

The burner igniters will

click until the flame ignites.

Burner flames should be

BLUE and stable with

no yellow tips, excessive

noise, or lifting of the

flame from the burner. If any of

these conditions exist, check that the air shutter (grill

and griddle only) or burner ports are not blocked or

clogged.

Remove any blockages that exist. If the flame is

too

yellow, indicating insufficient air, adjust the shutter

counterclockwise to increase air inlet (grill and

grid-

dle only).

CAUTION! A qualified technician must make

burner adjustments at the time of installation.

Improper or lack of adjustments may cause harmful

by

-

products or void your warranty!

WARNING! Gas line cannot be run inside back

cover of range. Run gas line in channel in back

of range.

HOOK UP

The open top burner flames should be approximately

1" to 1

-

1/4" High.

NATURAL GAS REQUIREMENTS:

PROPANE (LP) GAS REQUIREMENTS:

Inlet Connection: 1/2" N.P.T.

Min. 5/8" Dia. Flex Line.

Supply Pressure: 6" to 14" W.C.

Inlet Connection: 1/2" N.P.T.

Min. 5/8" Dia, Flex Line.

Supply Pressure: 11" to 14" W.C.

A Regulator is required at the LP source to provide

a maximum of 14" W.C. pressure to the range

regulator.

thathasbeenpermanently

mounted

totherangebody.

GAS HOOK

-

UP / TESTING AND ADJUSTMENTS

Loading ...

Loading ...

Loading ...