Loading ...

Loading ...

Loading ...

Mounting and Using Cutting

(Type 1) Wheels

Cutting wheels include diamond wheels and abrasive discs. Abrasive

cutting wheels for metal and concrete use are available. Diamond

blades for concrete cutting can also be used.

WARNING: A closed, 2-sided cutting wheel guard is not included

with this tool but is re quired when using cutting wheels. Fail ure to use

proper flange and guard can re sult in injury resulting from wheel

breakage and wheel contact. See the Accessories Chart for more

information.

MOUNTING CLOSED (TYPE 1) GUARD (FIG. 18 – 20)

WARNING: If present, the ONE TOUCH™ guard screw, lever and

spring must be removed before attempting to mount the closed

(Type1) guard. The removed parts must be retained and reinstalled

to use the ONE TOUCH™ guard. Noting the position of these parts

before disassembly will aid in reassembly.

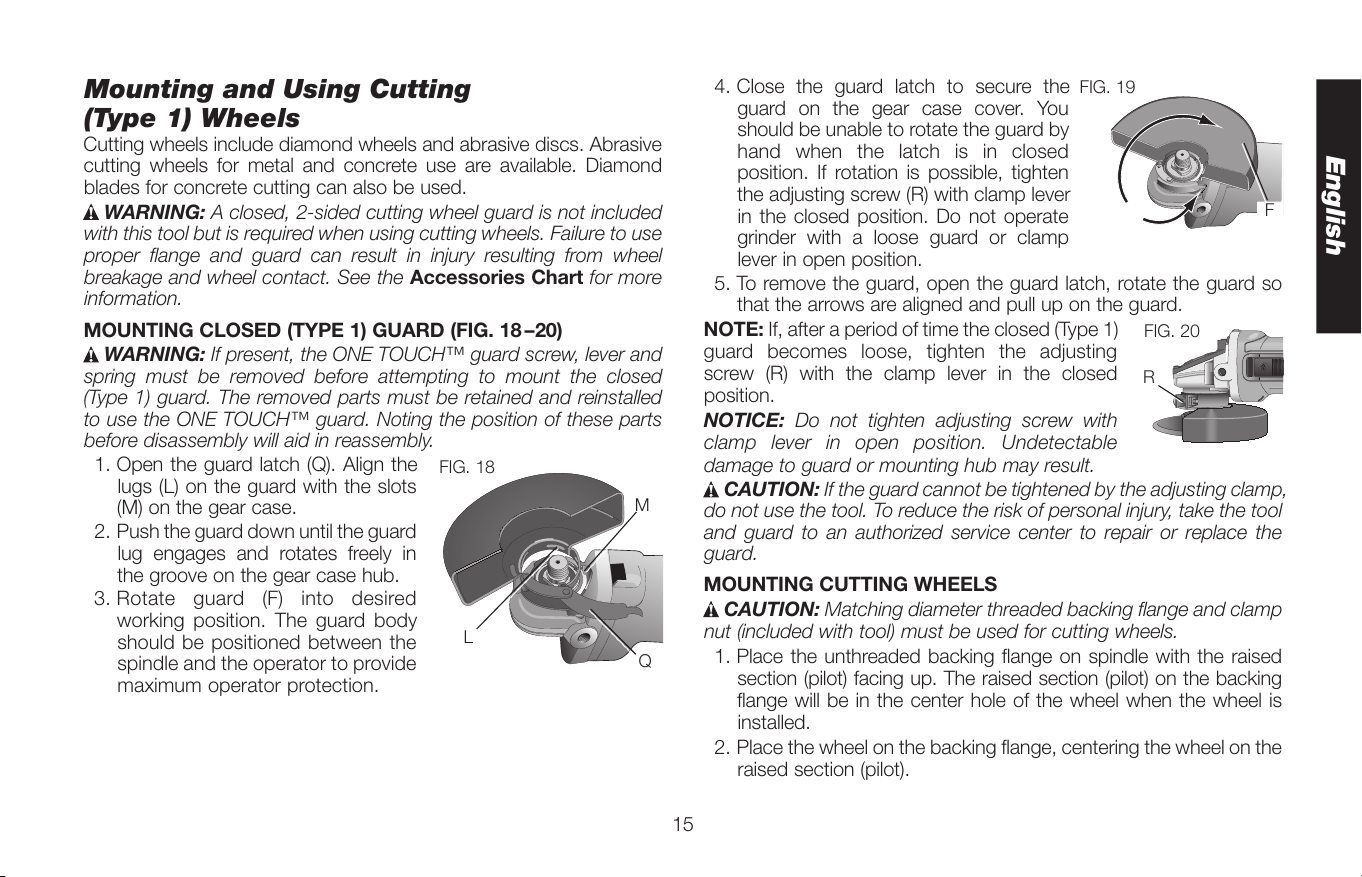

1. Open the guard latch (Q). Align the

Q

L

M

FIG. 18

lugs (L) on the guard with the slots

(M) on the gear case.

2. Push the guard down until the guard

lug engages and rotates freely in

the groove on the gear case hub.

3. Rotate guard (F) into desired

working position. The guard body

should be positioned between the

spindle and the operator to provide

maximum operator protection.

4. Close the guard latch to secure the

F

FIG. 19

guard on the gear case cover. You

should be unable to rotate the guard by

hand when the latch is in closed

position. If rotation is possible, tighten

the adjusting screw (R) with clamp lever

in the closed position. Do not operate

grinder with a loose guard or clamp

lever in open position.

5. To remove the guard, open the guard latch, rotate the guard so

that the arrows are aligned and pull up on the guard.

NOTE: If, after a period of time the closed (Type 1)

R

FIG. 20

guard becomes loose, tighten the adjusting

screw (R) with the clamp lever in the closed

position.

NOTICE: Do not tighten adjusting screw with

clamp lever in open position. Undetectable

damage to guard or mounting hub may result.

CAUTION: If the guard cannot be tightened by the adjusting clamp,

do not use the tool. To reduce the risk of personal injury, take the tool

and guard to an authorized service center to repair or replace the

guard.

MOUNTING CUTTING WHEELS

CAUTION: Matching diameter threaded backing flange and clamp

nut (included with tool) must be used for cutting wheels.

1. Place the unthreaded backing flange on spindle with the raised

section (pilot) facing up. The raised section (pilot) on the backing

flange will be in the center hole of the wheel when the wheel is

installed.

2. Place the wheel on the backing flange, centering the wheel on the

raised section (pilot).

English

15

Loading ...

Loading ...

Loading ...